Locking device and gas compressor and gas turbine comprising same

A compressor and interlocking device technology, which is applied in the field of gas turbines and compressors, can solve problems affecting the stress strength of blade roots and discs, achieve rapid installation and removal, reasonable locking structure design, and reduce the loss of aerodynamic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

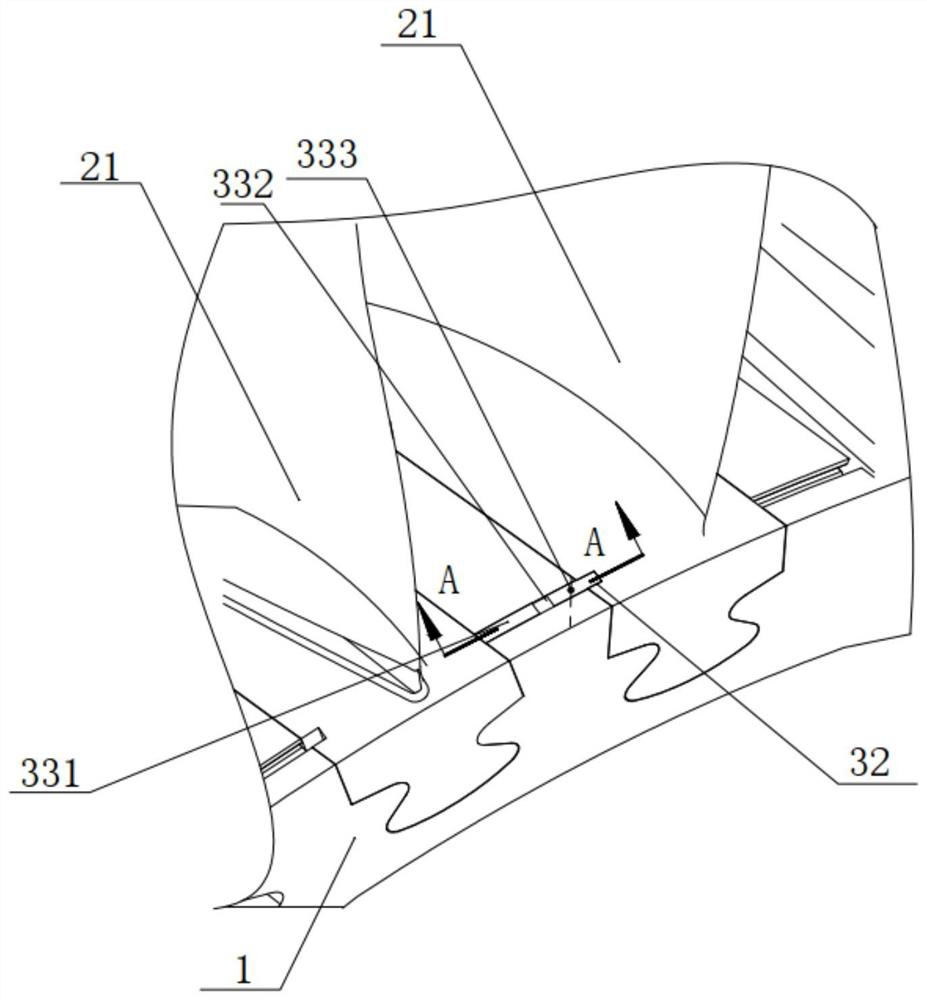

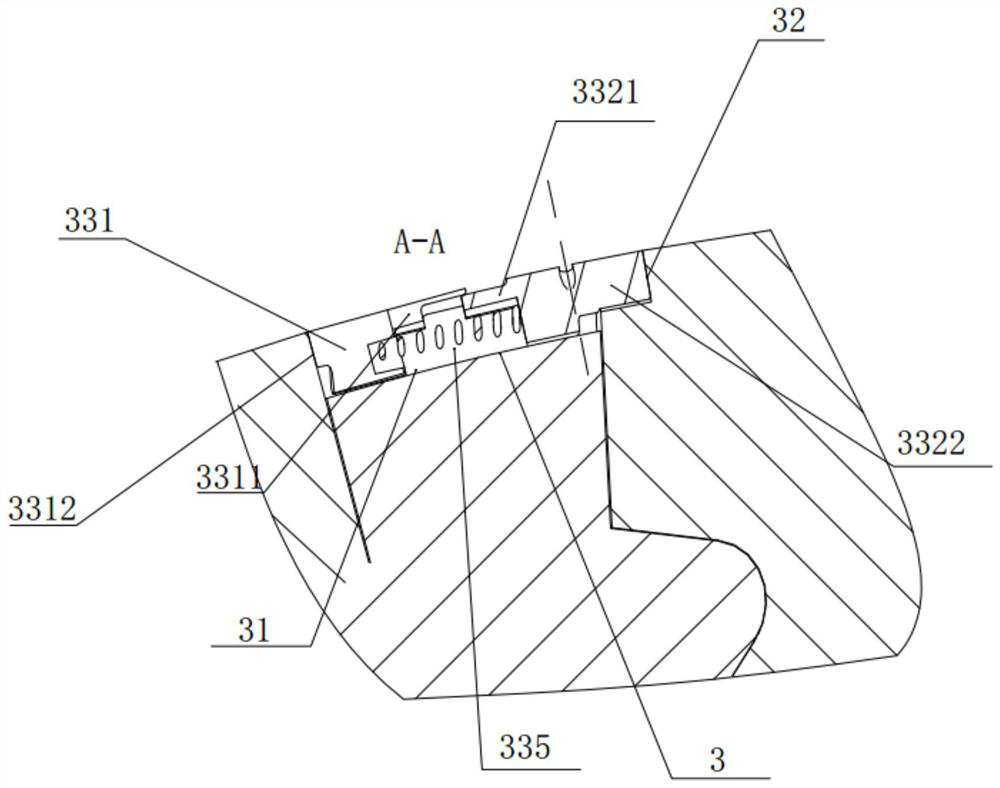

[0052] The compressor rotor blade 2 locking structure 3 provided in this embodiment includes a first installation part arranged on the wheel disk 1, a second installation part arranged on the blade root 21, and the locking structure 3 of the control blade 2 on the wheel disk 1. Interlock 33. Wherein, the interlocking device 33 is disposed between the first mounting portion and the second mounting portion, and the interlocking device 33 is operable between a locked position and an open position. In the locked position, the interlocking device 33 cooperates with the first mounting portion and the second mounting portion to limit the axial displacement of the blade 2 . That is, when in the locked position, the interlocking device 33 is locked and limited between the first installation part and the second installation part, so that the first installation part and the second installation part cannot move relative to each other, and then the blade 2 is locked on the wheel 1 superio...

Embodiment 2

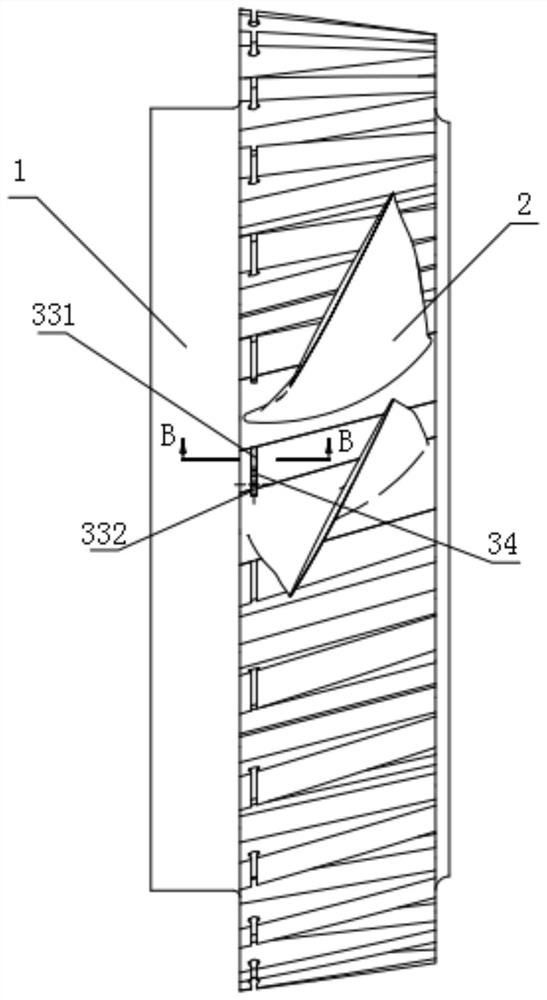

[0065] This embodiment provides a compressor and a gas turbine with the above-mentioned locking structure 3 on the basis of the above-mentioned embodiments. The compressor provided in this embodiment includes a rotor, and the rotor includes a disc 1 and blades 2 , the blade roots 21 of the blades 2 are installed on the disc 1 of the rotor, specifically arranged in the slots of the blades 2 of the disc 1 . The disc 1 is provided with a first locking groove 31 for the locking structure 3, the blade root 21 is provided with a second locking groove 32 for the locking structure 3, and the compressor also includes the locking structure as described in Embodiment 1 3.

[0066] This embodiment also provides a gas turbine with the above-mentioned compressor, and since the locking structure 3 of the compressor provided by this embodiment can reduce the impact on the strength of the compressor, it is especially suitable for heavy-duty gas turbines with higher strength requirements .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com