Fracture-vug type reservoir productivity determination method and system considering stress sensitivity

A stress-sensitive, fracture-cavity technology, applied in special data processing applications, instruments, design optimization/simulation, etc., can solve the problem of inability to accurately characterize the productivity relationship of fractured reservoirs and provide effective guidance for the development of fractured-cavity reservoirs and other issues to achieve the effect of ensuring scientificity and accuracy, accurate production capacity changes, and improved applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

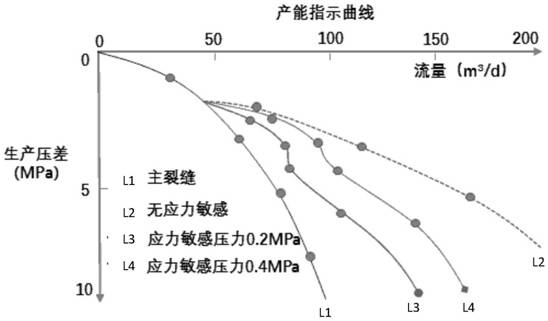

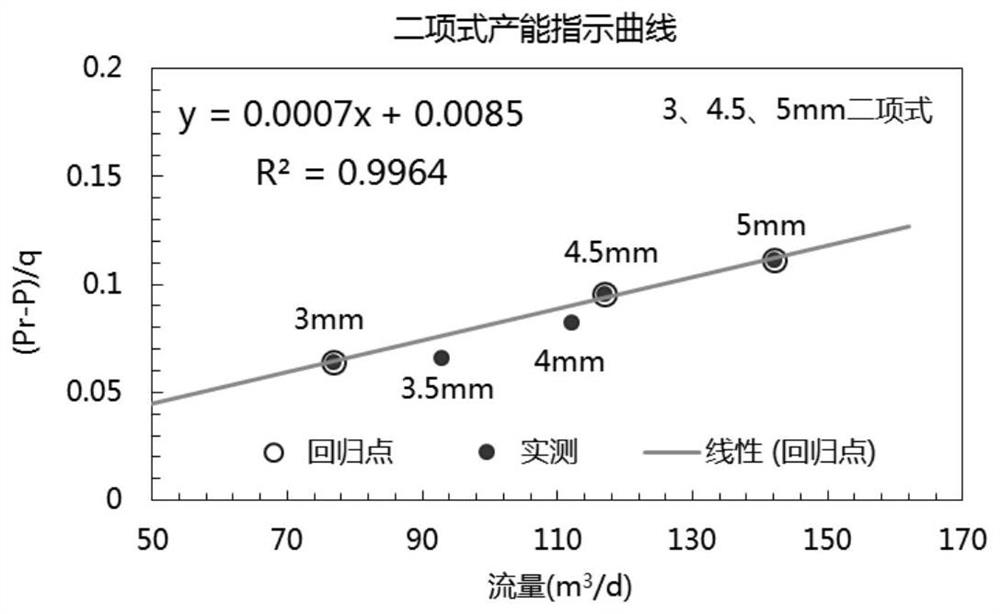

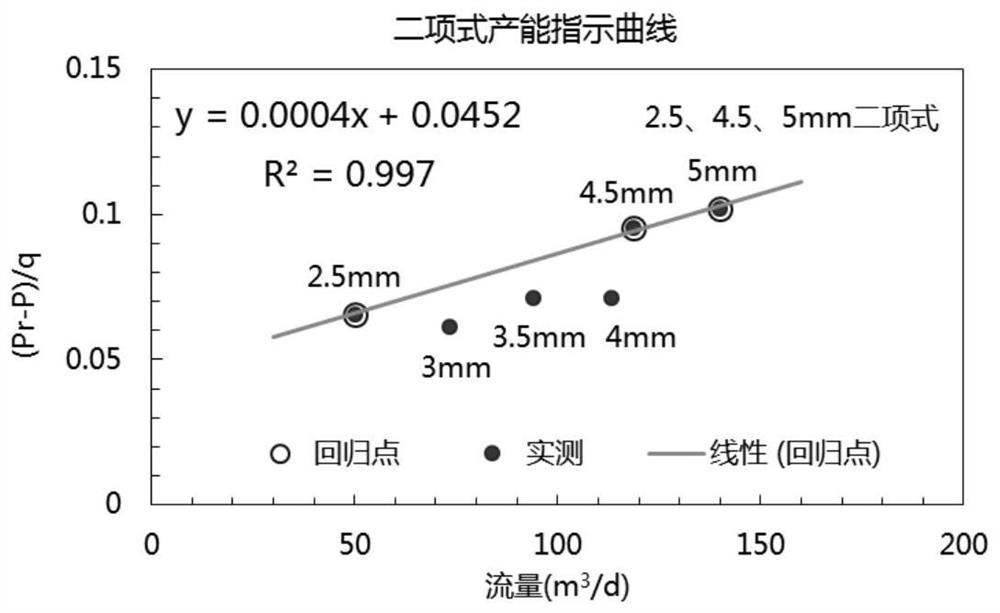

[0070] figure 2 A schematic flowchart of the method for determining the productivity of a fractured-cavity reservoir considering stress sensitivity provided in Embodiment 1 of the present invention is shown. Refer to figure 2 It can be seen that the method includes the following steps:

[0071] Step S110 , taking the single fracture-cavity physical model as the main fracture-cavity system model, and expanding the secondary fracture-cavity system model based on the main fracture-cavity model to form a parallel fracture-cavity conceptual model including the main fracture-cavity system model and the secondary fracture-cavity system model.

[0072] Specifically, in practical applications, the process of expanding the secondary fracture-hole system model based on the primary fracture-hole model may include:

[0073] Taking a fracture and a cave as a fracture-cavity unit, the sub-fractures of the secondary fracture-cave system are connected to the set position of the main fracture ...

Embodiment 2

[0167] Based on other aspects of the above embodiments, the present invention also provides a stress-sensitive fracture-vug reservoir productivity determination system, which is used to perform the methods or steps in any one or more of the above embodiments. Figure 9 A schematic diagram of the structure of the fracture-cavity reservoir productivity determination system considering stress sensitivity in the present invention is shown, such as Figure 9As shown, the system includes:

[0168] Parallel model building module 91, which is used to use the single-slit-cavity physical model as the main crack-cavity system model, expand the secondary crack-cavity system model based on the main crack-cavity model, and form a main crack-cavity system model and secondary crack-cavity system model. Conceptual model of parallel seams and holes;

[0169] A permeability model building module 93, which is used to build a corresponding permeability decrease mathematical model based on the par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com