Automatic packaging machine for supply room

A supply room, automatic technology, applied in the directions of packaging, transportation packaging, and packaging objects, etc., can solve the problems of inconvenient automatic packaging and packaging processing of medical devices, large human resources, time-consuming and laborious, etc., to achieve the effect of convenient automatic packaging processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

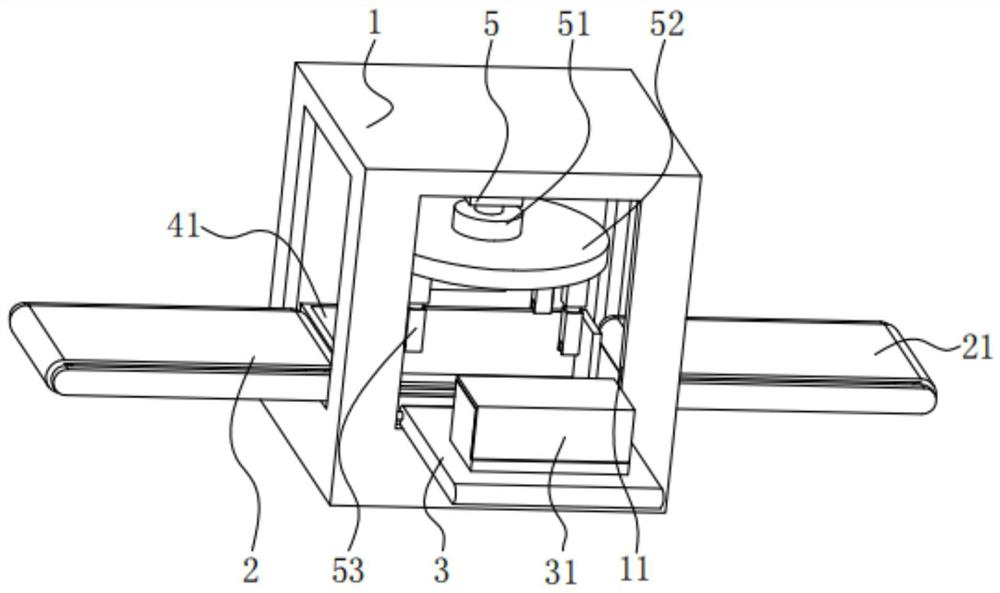

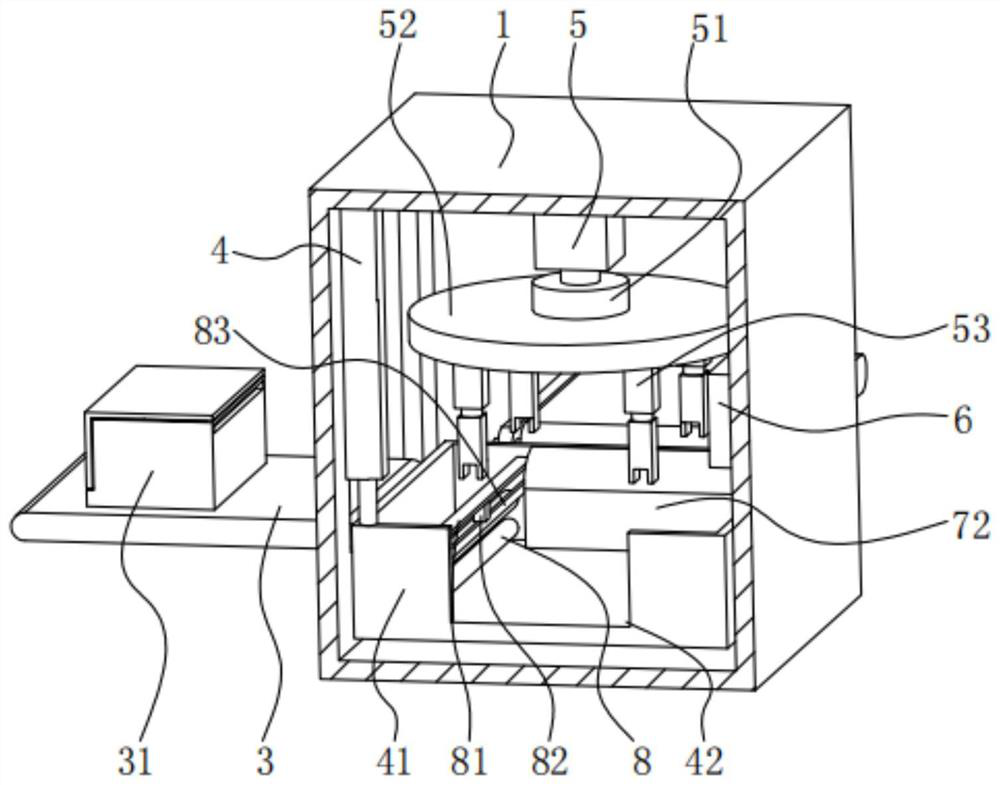

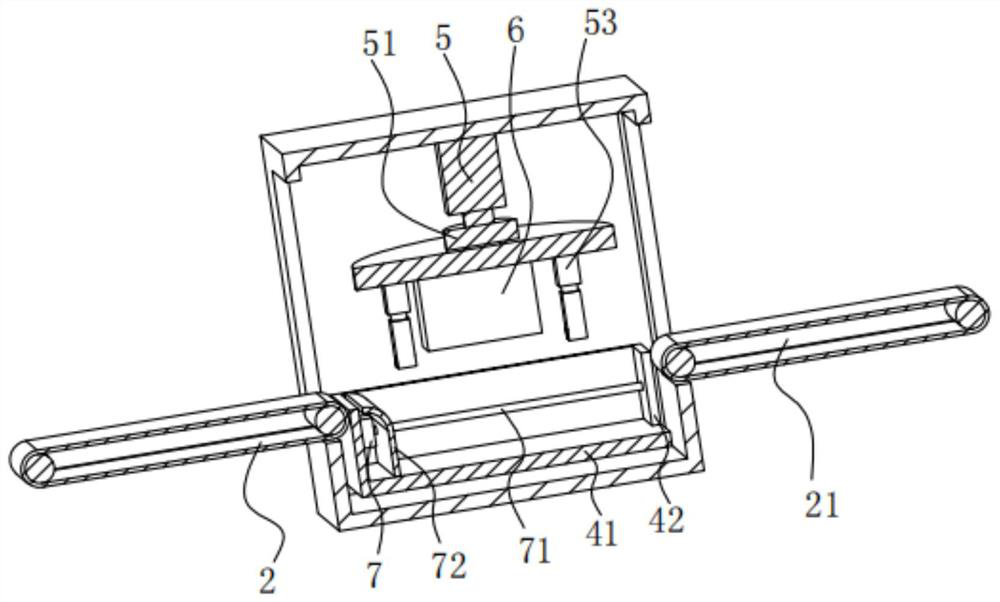

[0046] like Figure 1-Figure 3 As shown, the present invention provides a supply room automatic packing machine, including a box body 1, a first conveying assembly 2 and a second conveying assembly 21, the first conveying assembly 2 is installed at the input end of the box body 1, The first conveying assembly 2 is used for conveying the medical equipment. When the medical equipment is conveyed, it can be transmitted to the input end of the support frame 41 through the first conveying assembly 2, so as to facilitate the automatic feeding of the medical equipment. The second conveying assembly 21 is installed At the output end of the box body 1, the second conveying assembly 21 is used to receive and transport the packaged instrument package, so as to facilitate the automatic output of the packaged medical equipment. The side of the box body 1 is provided with a connection port 11 , the connection port 11 communicates with the inside of the box body 1, which facilitates the inpu...

Embodiment 2

[0052] like figure 2 As shown, the inner wall of the box body 1 is provided with a conveying roller 8, and the inner wall of the box body 1 is fixedly installed with a fixed plate 81, and the bottom of the fixed plate 81 is fixedly installed with a third telescopic member 82, and the third telescopic The output end of the piece 82 is fixedly connected with a cutting blade 83, the conveying roller 8 is a double-roller conveying structure, the cutting blade 83 is located in the output direction of the conveying roller 8, and the conveying roller 8 adopts its own rotating power , and the conveying roller 8 adopts a double-roller structure, which is mainly used for clamping and conveying the input non-woven fabric. The surface of the double-roller has a clamping effect on the non-woven fabric, providing guarantee for the transportation of the non-woven fabric, and the support frame The surface of the inner wall of 41 is smooth, which can guarantee the stability of the non-woven f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap