Fully spliced concrete frame reinforcement device and its construction method

A technology of reinforcement device and construction method, applied in building maintenance, construction, building construction, etc., can solve the problems of poor synergy performance and low construction efficiency, and achieve the effect of good synergy performance, high construction efficiency and high degree of civilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

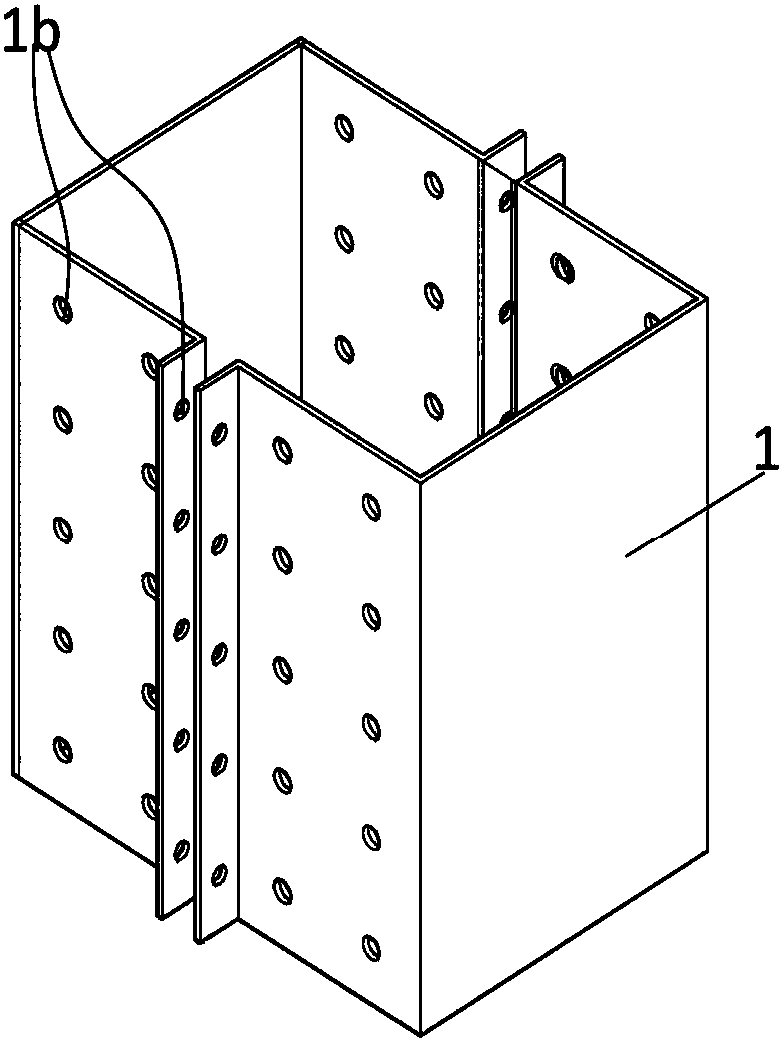

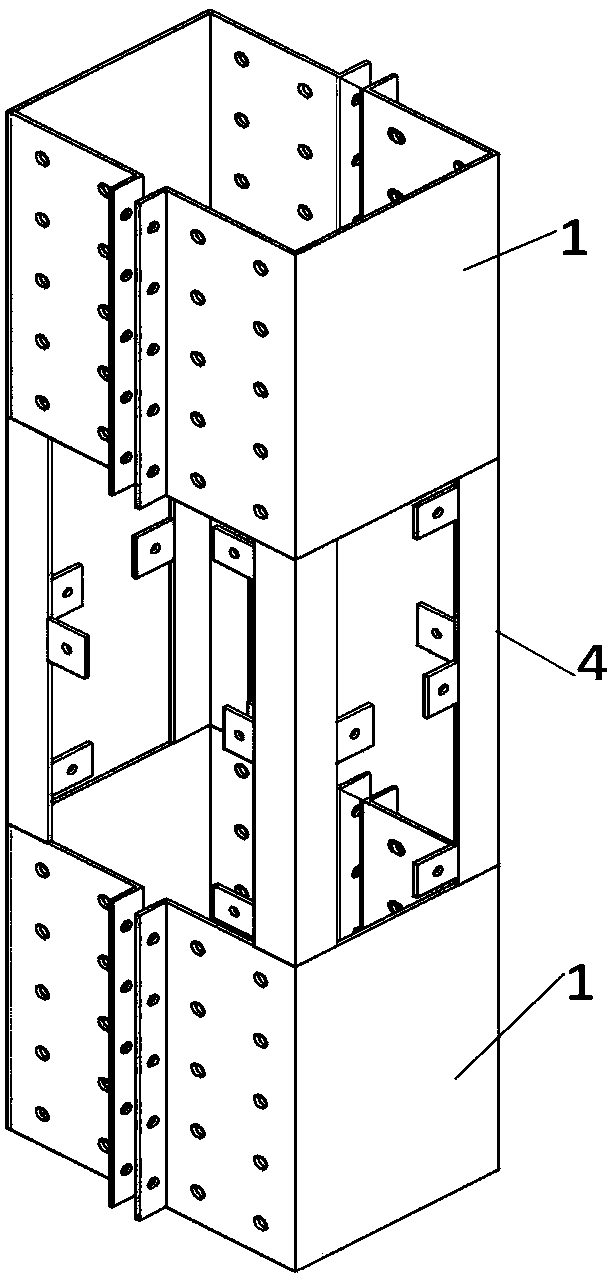

[0029] Such as figure 1 , figure 2 and image 3 As shown, the first embodiment of the present invention is introduced.

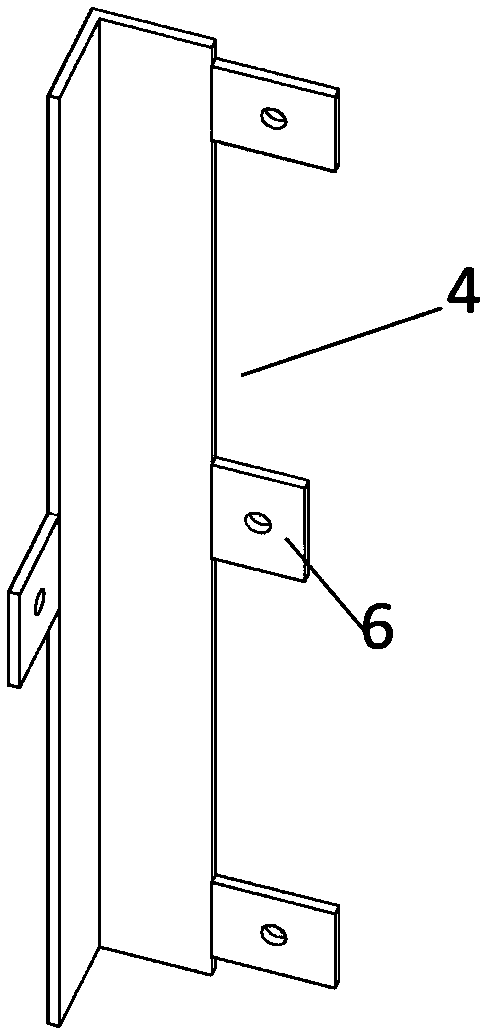

[0030] In this embodiment, the fully spliced concrete frame reinforcement device mainly includes channel steel 1, angle steel 4, tension screw 2, chemical anchor bolt 3 and strip 5, and its position is as follows image 3 shown. In this embodiment, for the convenience of description, the cavity in the channel steel used to wrap the concrete column is called the inside, and the cavity opposite to it is called the outside.

[0031] go to figure 1 , specifically describe the shape of the channel steel. The cross-section of the channel steel is generally in the shape of an oval, and the end is bent outward to form a flange portion, and a through hole 1b is provided on the flange portion and the side of the channel steel. The flange part is parallel to the central axis of the channel steel, and when the channel steel is fixed on the concrete column, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com