Polygonal lattice type grille-column structure sandwich panel

A polygonal, lattice-type technology, applied in the field of sandwich panels, can solve the problems of easy torsion, small stress, external buckling deformation of the grid wall, etc., and achieve the effect of improving strength, good bending stiffness and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

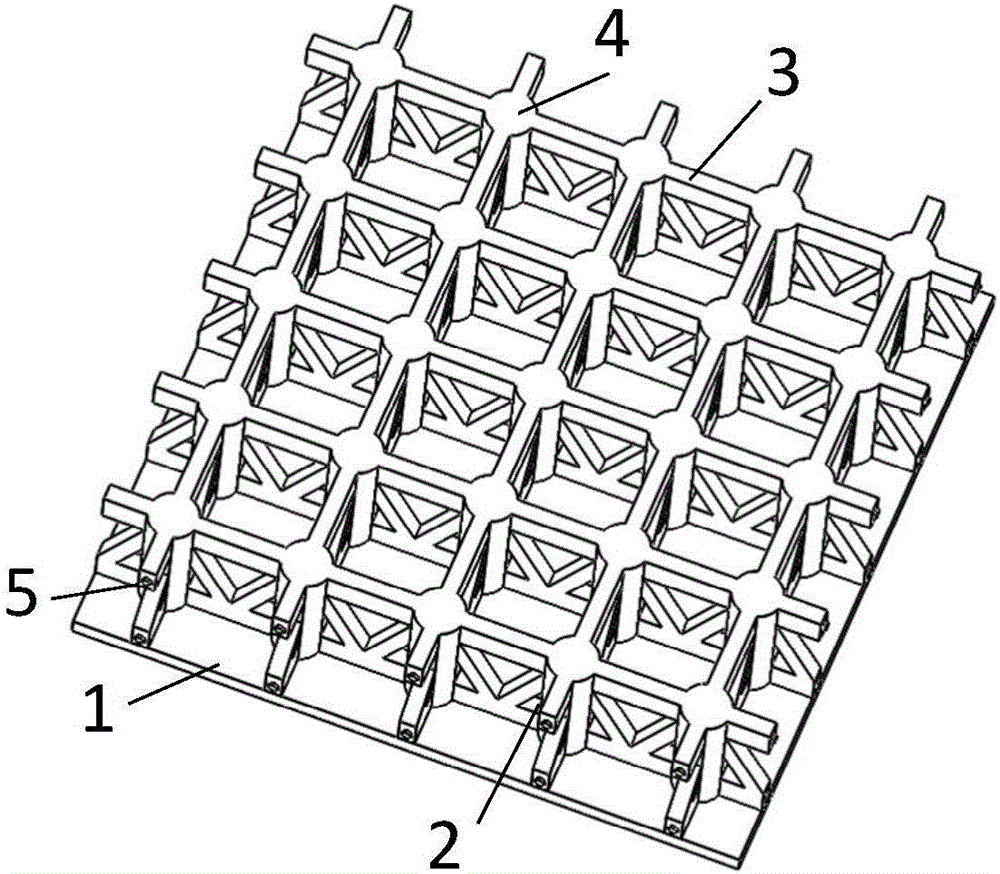

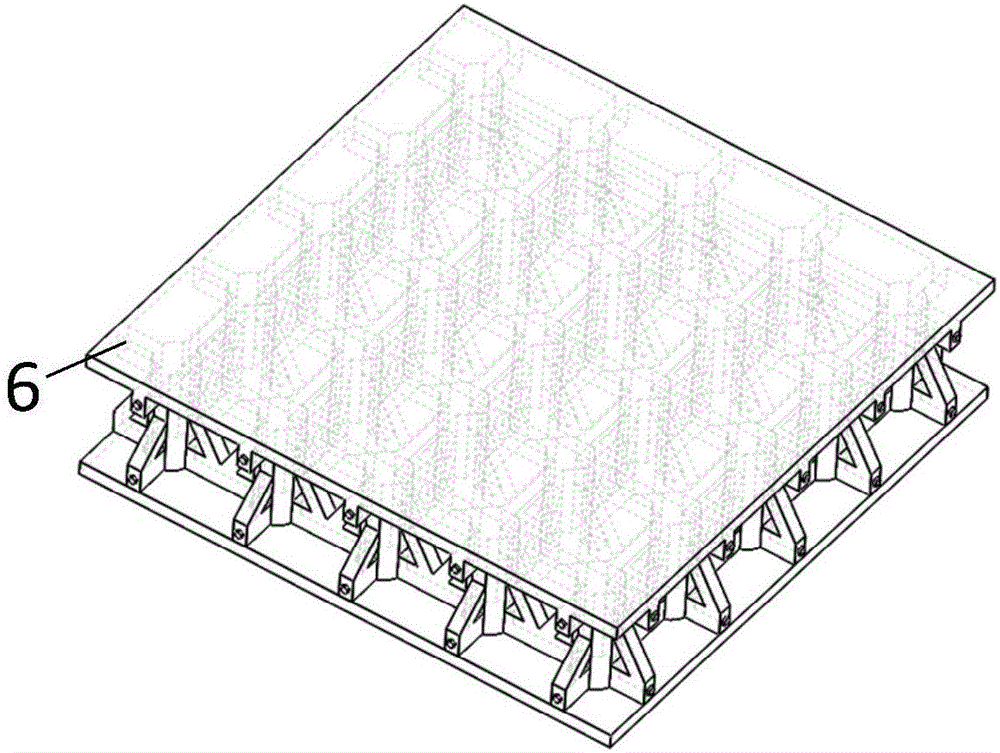

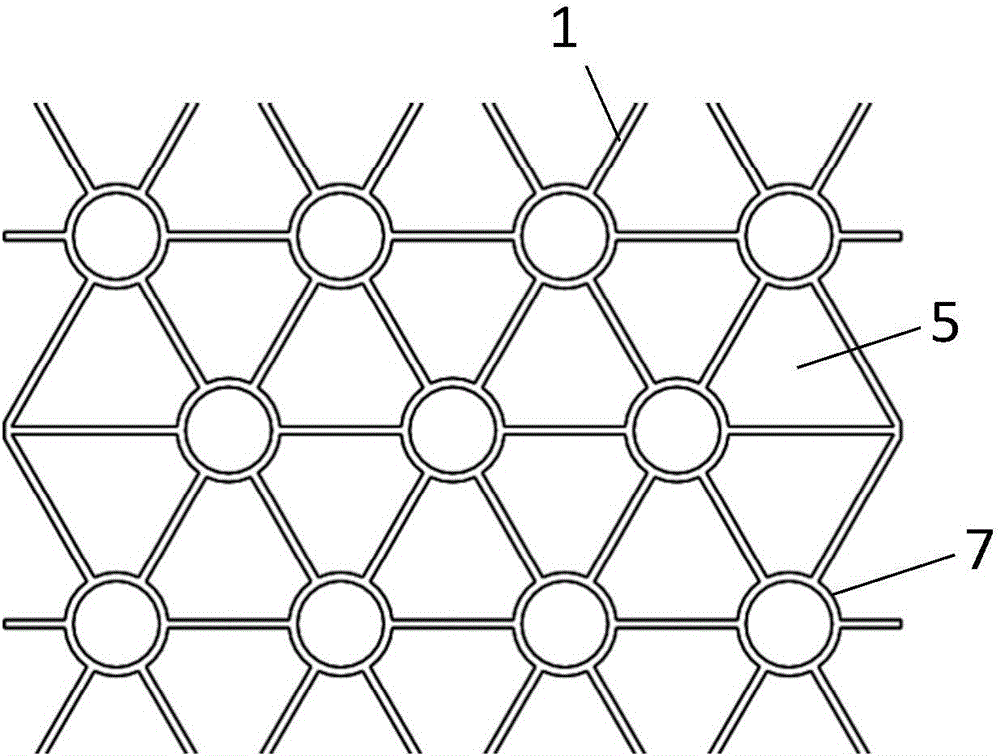

[0027] In the embodiment of the present invention, the quadrilateral grid unit is taken as an example, and the schematic diagram of the polygon grid grid-column structure sandwich panel is as follows figure 1 , figure 2 As shown, it includes an upper panel 6 , a lower panel 1 and a polygonal lattice grid-column structure 2 . The polygonal lattice grid-pillar structure 2 includes grid walls 3 and reinforcing columns 4 , and the reinforcing columns 4 are located at intersections of the grid walls 3 . The grid wall 3 is a grid structure, including a frame 31 and a space 32 inside the frame. The frame 31 is composed of an upper frame 311 , a lower frame 312 and a connecting piece 313 between the upper frame and the lower frame. The diameter or side length of the reinforcement column 4 is greater than the thickness of the grid wall 3 . Reinforcing ribs are provided in the upper frame 311 and the lower frame 312 .

[0028] The mechanical properties of the polygonal lattice grid-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com