Bottle blowing method

A bottle blowing machine and preform technology, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of voltage fluctuation, space congestion, waste of manpower and material resources, etc., and achieve the effect of stable clamping and good support.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

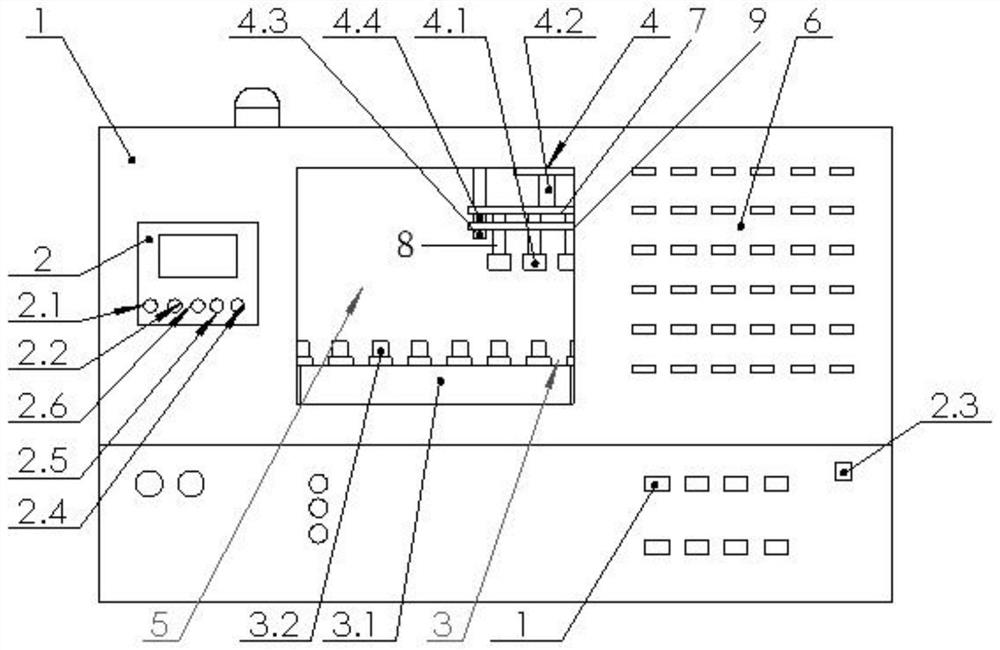

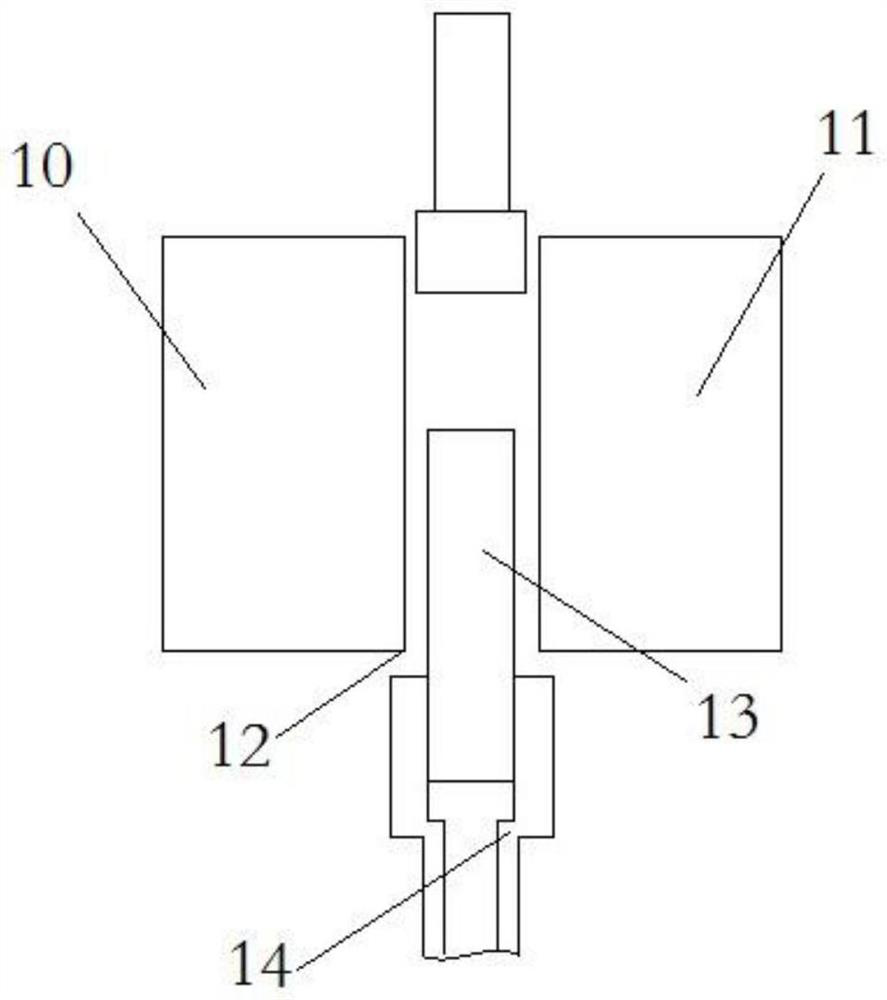

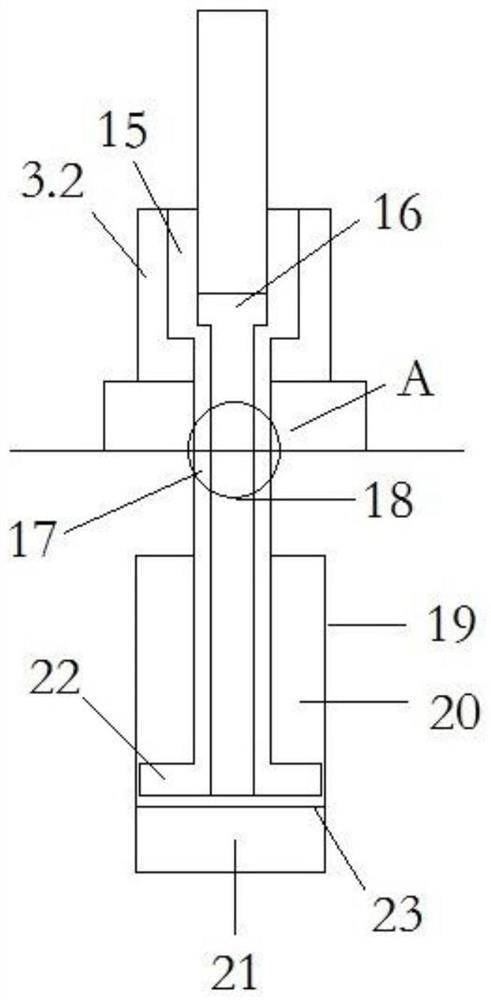

[0052] As shown in the figure: a bottle blowing method, which uses a bottle blowing machine to work. The bottle blowing machine includes a body, and the body is provided with a control module, a transmission module, a blow molding module, a heating cavity, a left mold, a right mold, and a stroke. A control device, a cooling cavity, and a heating device; the heating device is provided in the left mold and the right mold, and the control module controls the operation of the conveying module and the blowing module; the conveying module includes a conveying belt, and the conveying belt is provided with a lower Clamp; the blow molding module includes an upper frame, an upper clamp, a main rod, a three-way valve, a lower frame, a sub-rod, a wiring frame, a slide plate, and a four-way joint; the stroke control device includes a connecting part, an inner bush, a piston head , a piston rod, a lifting rod, a hydraulic cylinder, and a piston plate; the method includes the following steps:...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap