Anti-pressing transport packaging equipment for medical composite hard sheets

A technology of composite hard sheet and packaging equipment, which is applied in the field of pharmaceutical packaging and transportation, which can solve the problems of inconvenient operation, transportation, and no protective mechanism for transportation packaging equipment, so as to avoid rotation and extrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

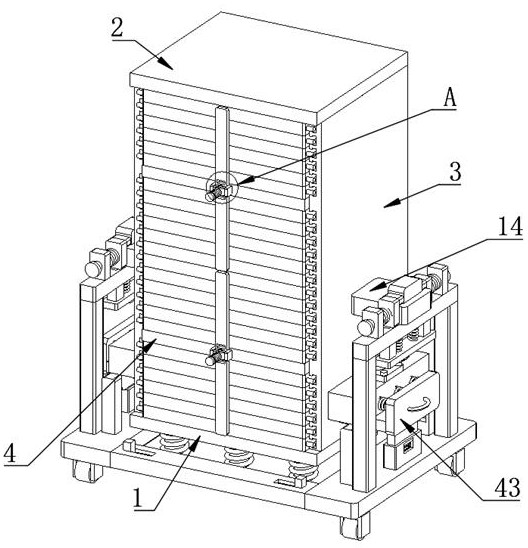

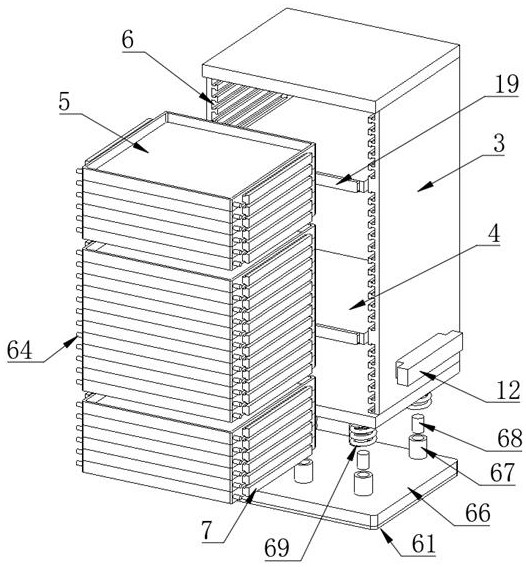

Embodiment 1

[0034] Embodiment one, by Figure 1 to Figure 8 Given, the present invention includes a support storage tray 1 and a support protection top plate 2, the support protection top plate 2 is arranged above the support storage tray 1, the top of the support storage tray 1 and the bottom of the support protection top plate 2 pass through two first limit sides The support plates 3 are connected, and the two first space-limiting side support plates 3 are connected by two fixed support partitions 4, and the sides of the two first space-limiting side support plates 3 are provided with a number of first slide grooves 6. The inner wall of one side of the first chute 6 communicates with one side of the first limiting side support plate 3, and a number of medical composite hard film storage boxes 5 are arranged between the two first limiting side support plates 3. Both sides of the composite hard sheet storage box 5 are fixedly connected with the first slide block 7, and one side of the fix...

Embodiment 2

[0037] Embodiment two, on the basis of embodiment one, by figure 1 , Figure 4 and Figure 5Provided, the anti-rotation mechanism includes a first fixed column 20 arranged on one side of the fixed support partition 4, the first fixed column 20 penetrates the storage box rotary baffle 19, and the penetration of the first fixed column 20 and the storage box rotary baffle 19 A bearing 21 is provided at the place, and one end of the first fixed column 20 is fixedly connected with the fixed support partition 4, and the other end of the first fixed column 20 is fixedly connected with the limiting plate 24, between the limiting plate 24 and the rotating baffle plate 19 of the storage box There is a first movable adjustment connection seat 22 between them, and the first fixed column 20 runs through the first movable adjustment connection seat 22. The first fixed column 20 is sheathed with a first compression spring 23, and the first compression spring 23 The two ends are respectivel...

Embodiment 3

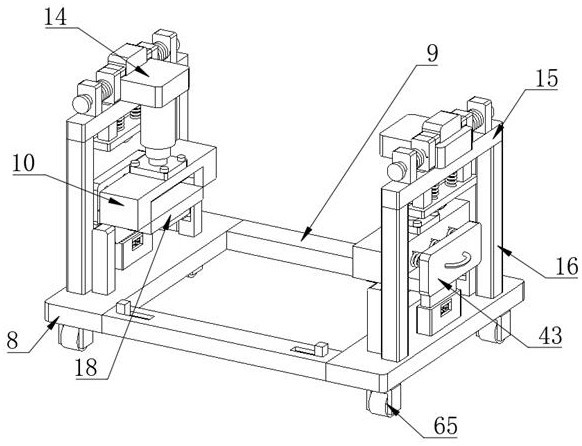

[0039] Embodiment three, on the basis of embodiment one, by image 3 and Image 6 Given, the anti-lifting mechanism includes a second movable adjustment connection seat 29 symmetrically arranged on both sides of the hydraulic telescopic cylinder fixed seat 14, and one side of the second movable adjustment connection seat 29 is fixedly connected with a first limit baffle 30, and a second The movable adjustment connecting seat 29 is provided with a second fixed plate 31 on the side away from the fixed seat 14 of the hydraulic telescopic cylinder. One side of the connection seat 29 is provided with a pull plate 32, and the side of the pull plate 32 close to the second fixed plate 31 is fixedly connected with a second fixed column 33, the second fixed column 33 runs through the second fixed plate 31, and the second fixed column One end of 33 is fixedly connected with the second movable adjustment connection seat 29, and the outside of the second fixed column 33 is sleeved with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com