A kind of method for growing indium phosphide single crystal by vgf method

An indium phosphide and single crystal technology is applied in the field of indium phosphide single crystal preparation, which can solve the problem of uneven distribution of carrier concentration and electron mobility, affecting the application life and cost of high-power microwave devices, and indium phosphide single crystal. The problem of low pass rate, etc., achieves the effect of increasing automatic temperature control and temperature adjustment functions, uniform resistivity distribution ratio, and stable vertical orientation crystallization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

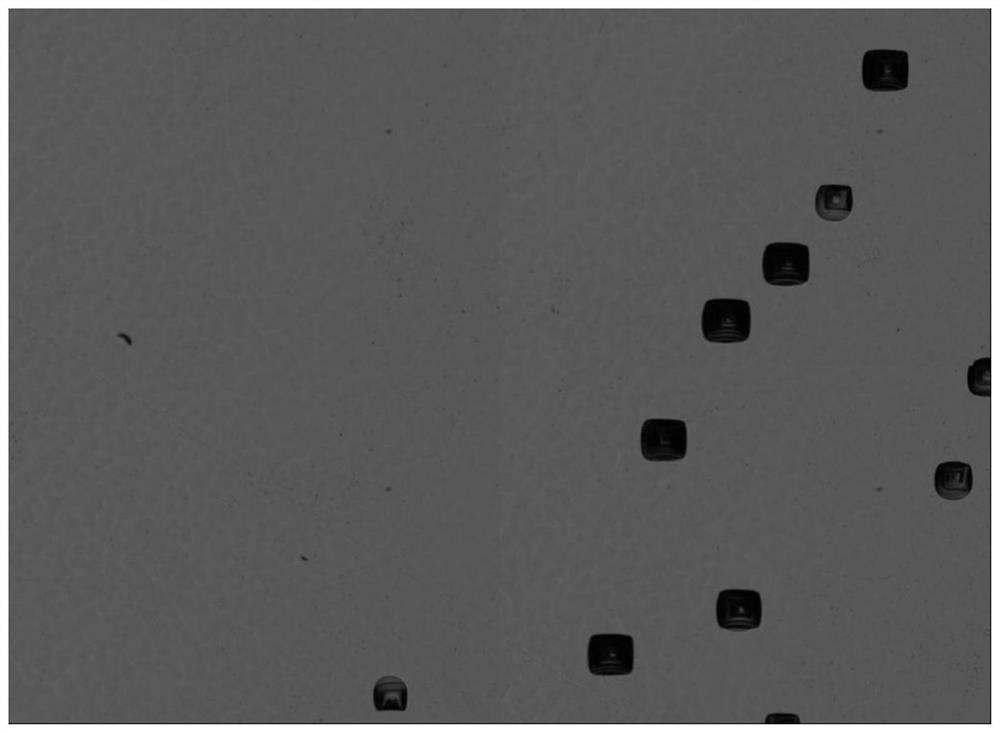

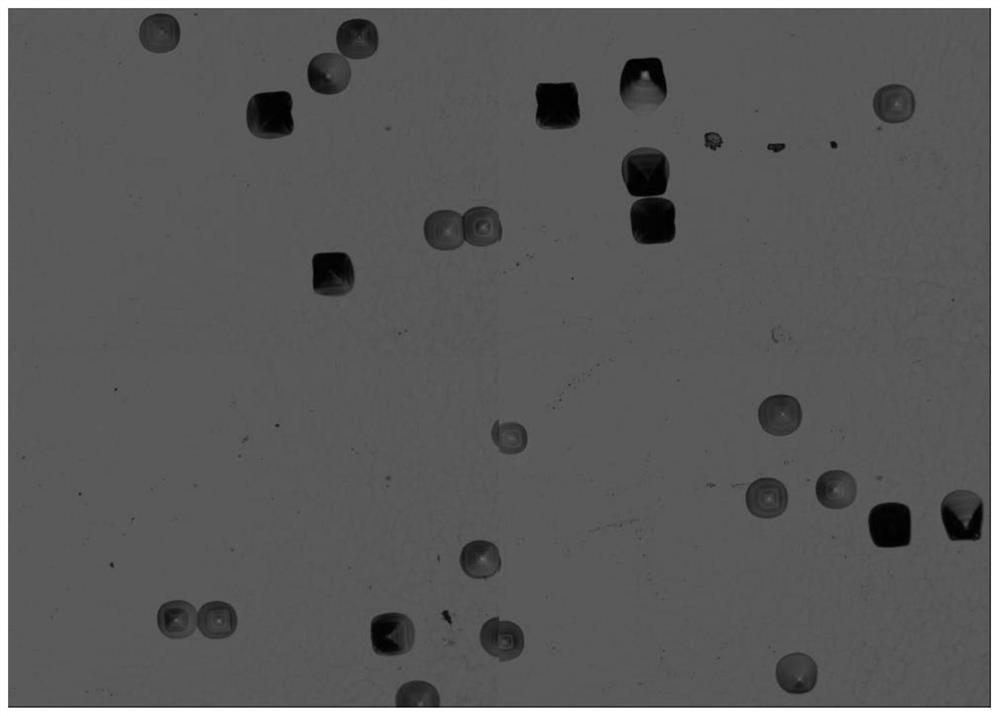

Image

Examples

Embodiment 1

[0029] The process of indium phosphide single crystal growth: material preparation → furnace preparation → furnace loading → heating melting material → melting seed → growth → cooling annealing → furnace demoulding;

[0030] 1. Material preparation: in a 100-level environment, sequentially combine seed crystal, diboron trioxide (water content less than 200PPm), high-purity red phosphorus (5N), dopant (5N indium trisulfide or 5N high-purity iron), polycrystalline material (mobility > 2000cm 2 / V.S) into the cleaned PBN crucible, cover with a quartz cap, put into a quartz material tube, vacuumize it, and then carry out oxyhydrogen flame sealing and welding for use. Note: PBN crucible must be annealed with oxygen at high temperature (1200℃).

[0031] 2. Prepare the furnace, such as Figure 4 shown:

[0032] 2.1 Install the quartz material tube 8, the quartz furnace tube 7, the heating layer 6 and other conventional structures in sequence between the PBN crucible 10 and the hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com