Material collector without crushing aggregate

A technology of aggregates and aggregates, applied in the field of aggregates, can solve problems such as broken stones, affecting road construction quality, and changes in road gradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to clearly illustrate the technical characteristics of this patent, the following describes this patent in detail through specific implementation methods and in conjunction with the accompanying drawings.

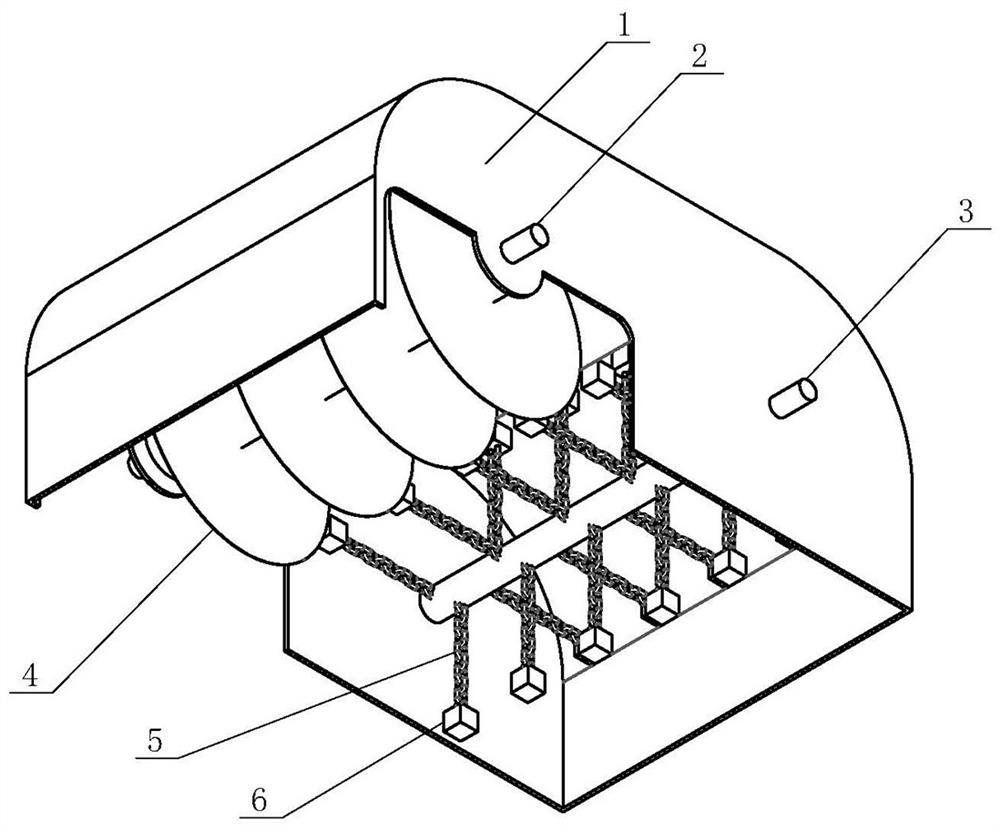

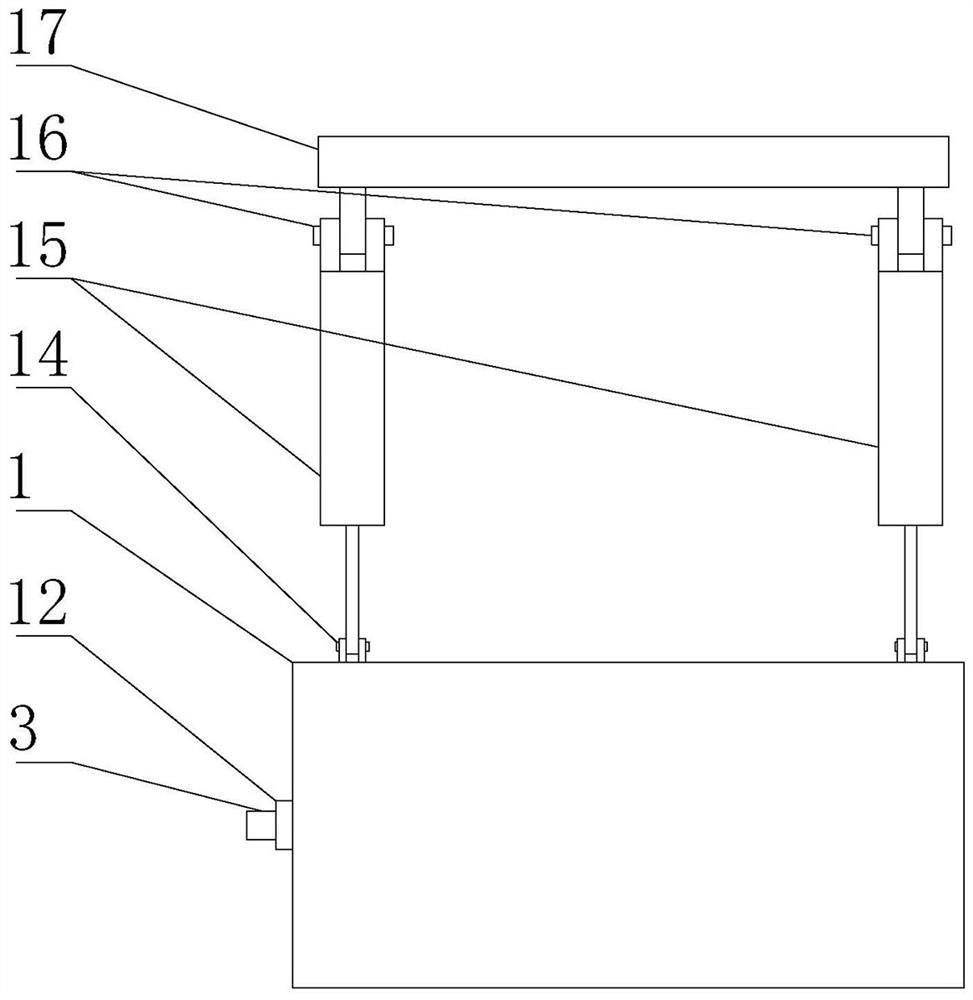

[0019] The present invention as Figure 1-2 As shown, the collector includes a casing 1, a centrifugal loosening mechanism and a spiral collecting mechanism, and the centrifugal loosening mechanism is located on the front side of the spiral collecting mechanism; when in use, the centrifugal loosening mechanism will first contact the road surface and carry out the process on the road surface. Loose, after that, the screw aggregate mechanism on the rear side transports the loose asphalt mixture to one side for collection.

[0020] The centrifugal loosening mechanism includes a rotary power source, a centrifugal hammer drive shaft 3 and a plurality of centrifugal hammers 6, the centrifugal hammer drive shaft 3 is rotatably connected in the housing 1, and is dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com