Self-priming non-clogging diaphragm pump

A non-clogging, diaphragm pump technology, used in pumps, pumps with flexible working elements, liquid variable-capacity machines, etc., can solve the problems of diaphragm damage, affecting the effect of pump liquid, and clogging of the liquid inlet port, to avoid excessive damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

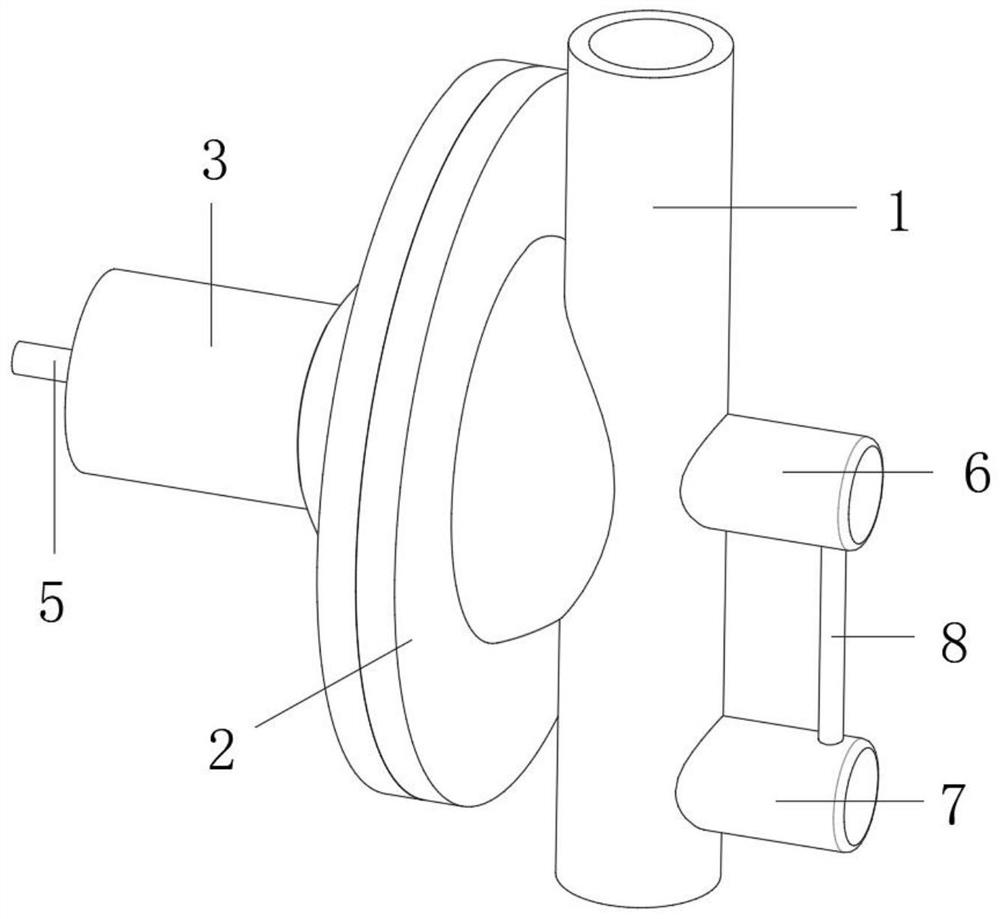

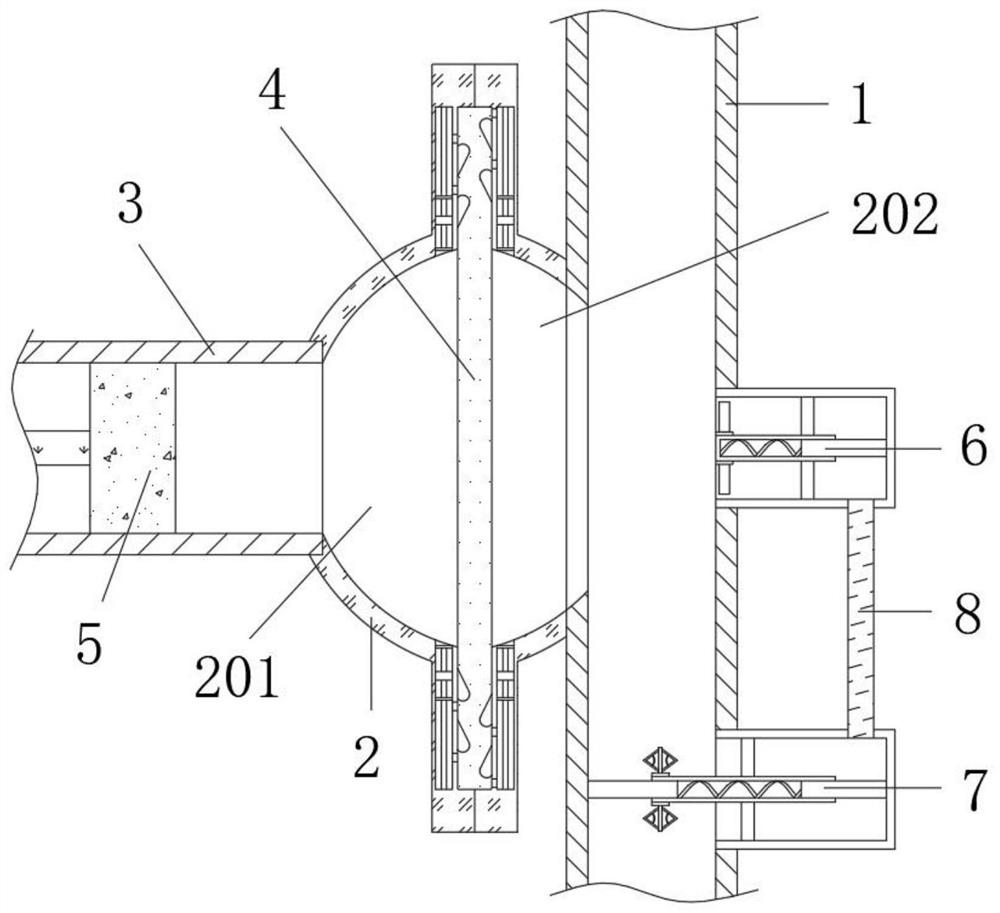

[0030] refer to figure 1 and figure 2 , a self-priming non-clogging diaphragm pump, including a pump liquid pipe 1, a diaphragm seat 2 and a fixed pipe 3 connected in sequence, a diaphragm 4 is fixed in the middle of the diaphragm seat 2, and a movable column is arranged in the fixed pipe 3 The plug 5, the side of the diaphragm 4 close to the movable plunger 5 in the diaphragm seat 2 is set as the driving cavity 201, and the side of the diaphragm 4 in the diaphragm seat 2 close to the pump liquid pipe 1 is set as the pump liquid chamber 202, and the pump liquid pipe 1 A first piston mechanism 6 is provided on the outer wall corresponding to the pump liquid chamber 202, and a second piston mechanism 7 is installed on the outer wall of the pump liquid pipe 1 close to the opening of the liquid inlet. The first piston mechanism 6 and the second piston mechanism 7 There is a connecting pipe 8 connected between them. Actually, when using this equipment to pump liquid, the diaphrag...

Embodiment 2

[0032] refer to figure 1 and figure 2, a self-priming non-clogging diaphragm pump, including a pump liquid pipe 1, a diaphragm seat 2 and a fixed pipe 3 connected in sequence, a diaphragm 4 is fixed in the middle of the diaphragm seat 2, and a movable movable pipe is arranged in the fixed pipe 3 The plunger 5, the side of the diaphragm 4 close to the movable plunger 5 in the diaphragm seat 2 is set as the driving cavity 201, and the side of the diaphragm 4 in the diaphragm seat 2 close to the pump liquid tube 1 is set as the pump liquid chamber 202, and the pump liquid A first piston mechanism 6 is provided on the outer wall of the tube 1 corresponding to the pump liquid chamber 202, and a second piston mechanism 7 is installed on the outer wall of the pump liquid tube 1 close to the opening of the liquid outlet. The first piston mechanism 6 and the second piston mechanism 7 is connected with a communication pipe 8, and the second piston mechanism 7 is used to dredge the liq...

Embodiment 3

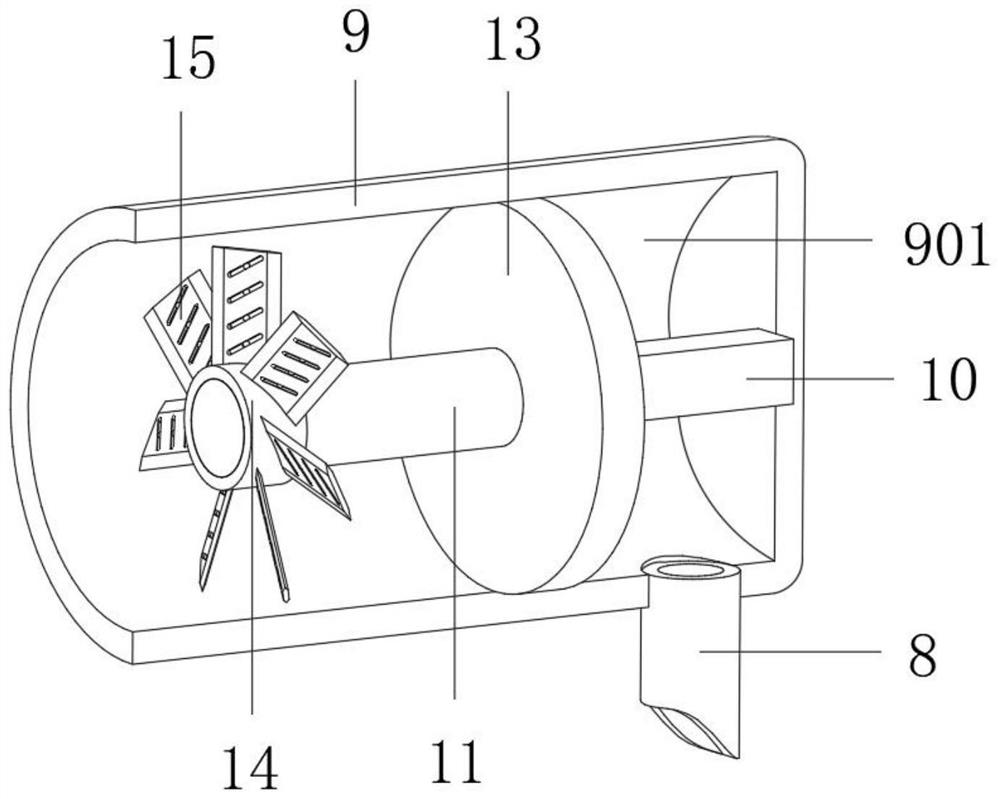

[0034] A self-priming non-clogging diaphragm pump, including a pump liquid pipe 1, a diaphragm seat 2 and a fixed pipe 3 connected in sequence, a diaphragm 4 is fixed in the middle of the diaphragm seat 2, and a movable column is arranged in the fixed pipe 3 The plug 5, the side of the diaphragm 4 close to the movable plunger 5 in the diaphragm seat 2 is set as the driving cavity 201, and the side of the diaphragm 4 in the diaphragm seat 2 close to the pump liquid pipe 1 is set as the pump liquid chamber 202, and the pump liquid pipe 1. A first piston mechanism 6 is provided at the position corresponding to the pump liquid cavity 202 on the outer wall, and a second piston mechanism 7 is provided on the outer wall of the pump liquid pipe 1 at the positions where the liquid inlet and the liquid outlet are opened. The first piston mechanism 6 and the A connecting pipe 8 is connected between the two second piston mechanisms 7, so that the change of the diaphragm 4 is used to dredge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com