Bearing for a biomass pellet machine

A technology of biomass particles and bearings, which is applied to bearings, shafts, bearings, bearing components, etc., can solve the problems of bearing overheating, affecting the service life of bearings, and affecting the processing efficiency of pellets, so as to prolong the service life and reduce maintenance costs , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

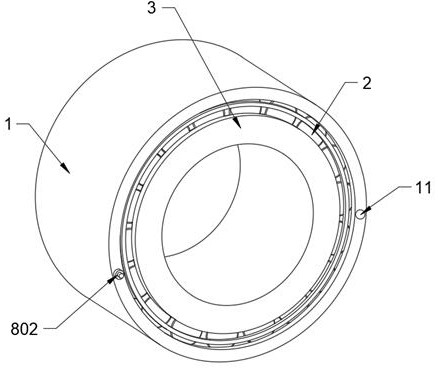

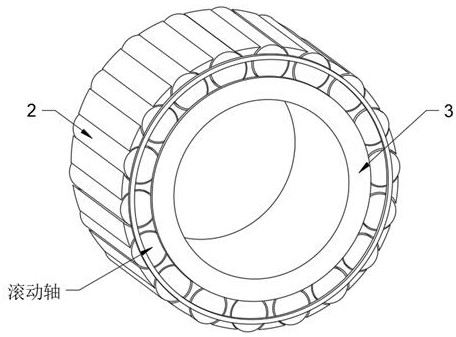

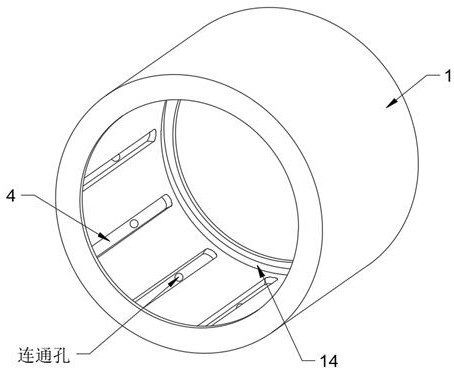

[0036] see Figure 1-4 , a bearing for a biomass pellet machine, including a stationary outer ring 1, a transmission middle layer 2, and a rotating inner ring 3 sequentially connected from outside to inside, and a lubricating oil storage tank is opened in the stationary outer ring 1, and the lubricating oil storage tank is close to the transmission The inner wall of one side of the middle layer 2 is installed with an oil replenishment mechanism 8, and the inner wall of the stationary outer ring 1 close to the transmission middle layer 2 is provided with a plurality of grease transfer grooves 4, and the inner wall of the grease transfer groove 4 near the oil replenishment mechanism 8 is fixedly installed with grease Supplementary strip 5, grease supplement strip 5 is connected with a brush oil bag 6 on the side close to the transmission middle layer 2, and the side of the grease supplement strip 5 away from the transmission middle layer 2 is fixedly installed with a one-way seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com