Semi-rigid node test device with adjustable rigidity

A test device, a semi-rigid technology, applied in the direction of measuring device, strength characteristics, using stable tension/pressure test material strength, etc., can solve the problems that cannot simulate the constraints of the joints at both ends of the test member, and the force situation does not match.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

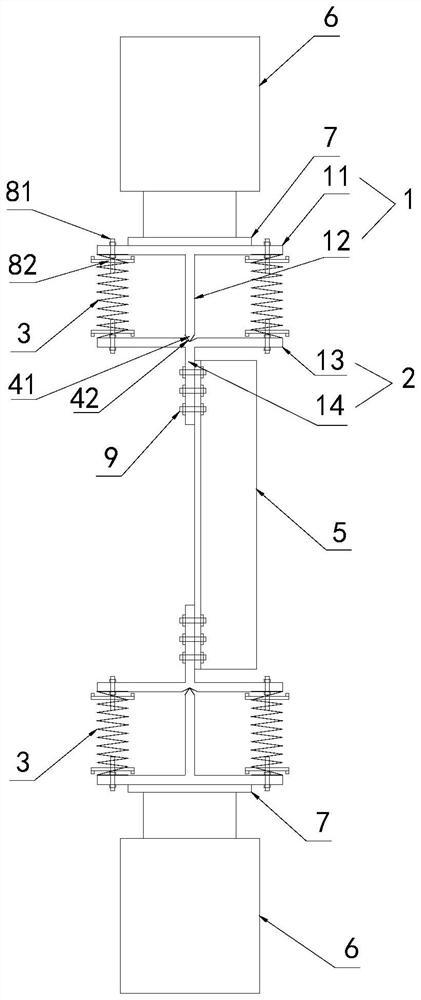

[0072] see Figure 1-Figure 2 , the present embodiment proposes a semi-rigid joint test device with adjustable stiffness, including two test assemblies arranged oppositely, a test member 5 is installed between the two test assemblies, and the two test assemblies are arranged up and down.

[0073] The upper test assembly includes a loading part 1 and a connecting part 2 , the loading part 1 is hinged to the connecting part 2 , and the loading part 1 can transfer load to the test member 5 through the connecting part 2 .

[0074] The loading part 1 includes a horizontally arranged plate one 11 and a vertically arranged plate two 12, the second plate 12 is fixedly connected to the middle position below the first plate 11, the first plate 11 and the second plate 12 form a T-shaped structure.

[0075] The connecting part 2 comprises a horizontally arranged board three 13 and a vertically arranged board four 14, the said board four 14 is fixedly connected to the middle position belo...

Embodiment 2

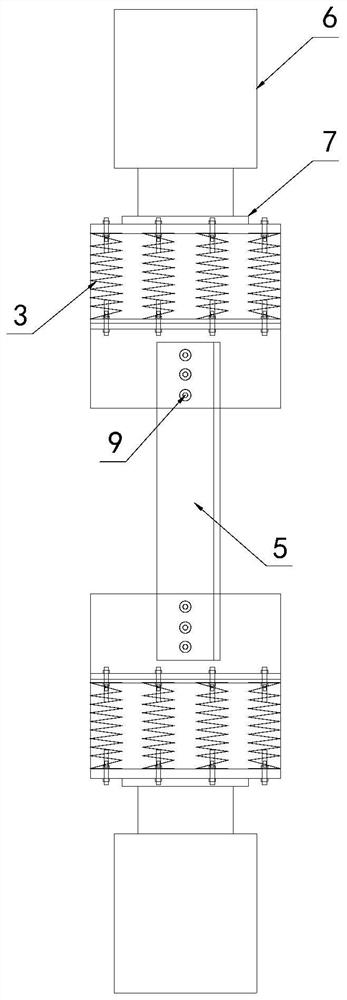

[0089] The difference between this embodiment and Embodiment 1 is that the constraining unit is fixedly connected to the first plate 11 and the third plate 13, specifically, one end of the spring is welded and fixed on the first plate 11, and the other One end is welded and fixed on the board three 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com