A kind of waste incineration fly ash stabilizer and its processing technology

A waste incineration fly ash and processing technology, which is applied in the field of fly ash stabilizers, can solve the problems of acid-base sensitivity of the stabilization system, large dosage, and unstable stabilization effect of heavy metals in fly ash, so as to achieve stable material state and reduce sensitivity Sex, reduce the effect of leaching toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

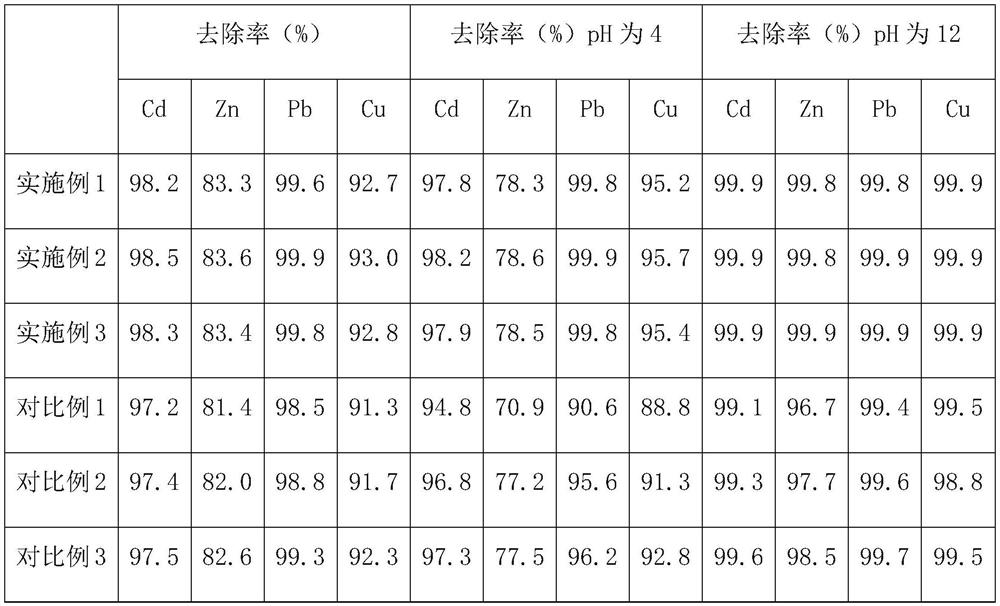

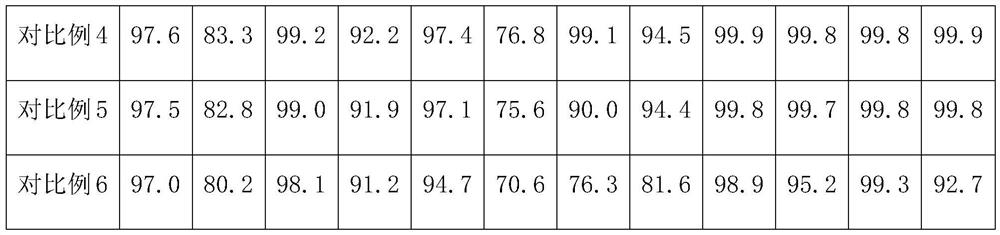

Examples

Embodiment 1

[0027] Take phytic acid, add glycidyl methacrylate and mix, pass nitrogen, add deionized water and potassium persulfate, stir and mix in nitrogen atmosphere, adjust the temperature of the system to 70 ° C, react for 7 hours, wash, and dry to obtain product A ; wherein the mass ratio of phytic acid and glycidyl methacrylate is 10:9.0;

[0028] Take product A, add methanol and mix, pass nitrogen, adjust the temperature of the system to 1 °C, in a nitrogen atmosphere, add ethylenediamine and trimethylolpropane triacrylate in turn, keep the temperature of the system at 1 °C, and under dark conditions The reaction was carried out for 72h, followed by distillation under reduced pressure. The process conditions were as follows: the temperature was 80°C and the pressure was 0.08MPa until the product had a constant weight to obtain product B; wherein the mass ratio of product A, ethylenediamine and trimethylolpropane triacrylate was 1.3 :1.8:1.0;

[0029] Mix 1-(3-dimethylaminopropyl)...

Embodiment 2

[0031] Take phytic acid, add glycidyl methacrylate and mix, pass nitrogen, add deionized water and potassium persulfate, stir and mix in nitrogen atmosphere, adjust the temperature of the system to 75°C, react for 7.5h, wash, and dry to obtain the product A; wherein the mass ratio of phytic acid and glycidyl methacrylate is 10:11.2;

[0032] Take product A, add methanol and mix, pass nitrogen, adjust the temperature of the system to 0 °C, in a nitrogen atmosphere, add ethylenediamine and trimethylolpropane triacrylate in turn, keep the temperature of the system at 0 °C, and under dark conditions The reaction was carried out for 75h, followed by distillation under reduced pressure. The process conditions were as follows: the temperature was 82°C and the pressure was 0.09MPa until the product had a constant weight to obtain product B; wherein the mass ratio of product A, ethylenediamine and trimethylolpropane triacrylate was 1.8 :2.4:1.7;

[0033] Mix 1-(3-dimethylaminopropyl)-...

Embodiment 3

[0035] Take phytic acid, add glycidyl methacrylate and mix, pass nitrogen, add deionized water and potassium persulfate, stir and mix in nitrogen atmosphere, adjust the temperature of the system to 80 ° C, react for 8 hours, wash, and dry to obtain product A ; Wherein the mass ratio of phytic acid and glycidyl methacrylate is 10:13.5;

[0036] Take product A, add methanol and mix, pass nitrogen, adjust the temperature of the system to 0 °C, in a nitrogen atmosphere, add ethylenediamine and trimethylolpropane triacrylate in turn, keep the temperature of the system at 0 °C, and under dark conditions The reaction was carried out for 80h, followed by distillation under reduced pressure. The process conditions were as follows: the temperature was 85°C and the pressure was 0.10MPa until the product had a constant weight to obtain product B; wherein the mass ratio of product A, ethylenediamine and trimethylolpropane triacrylate was 2.4 :3.0:2.5;

[0037] Mix 1-(3-dimethylaminopropyl)-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com