Fixed-torque concrete mixer and concrete mixing method

A concrete mixer and constant torque technology, which are applied in cement mixing devices, chemical instruments and methods, clay preparation devices, etc., can solve problems such as motor overload and inability to quantitatively detect the viscosity of concrete slurry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

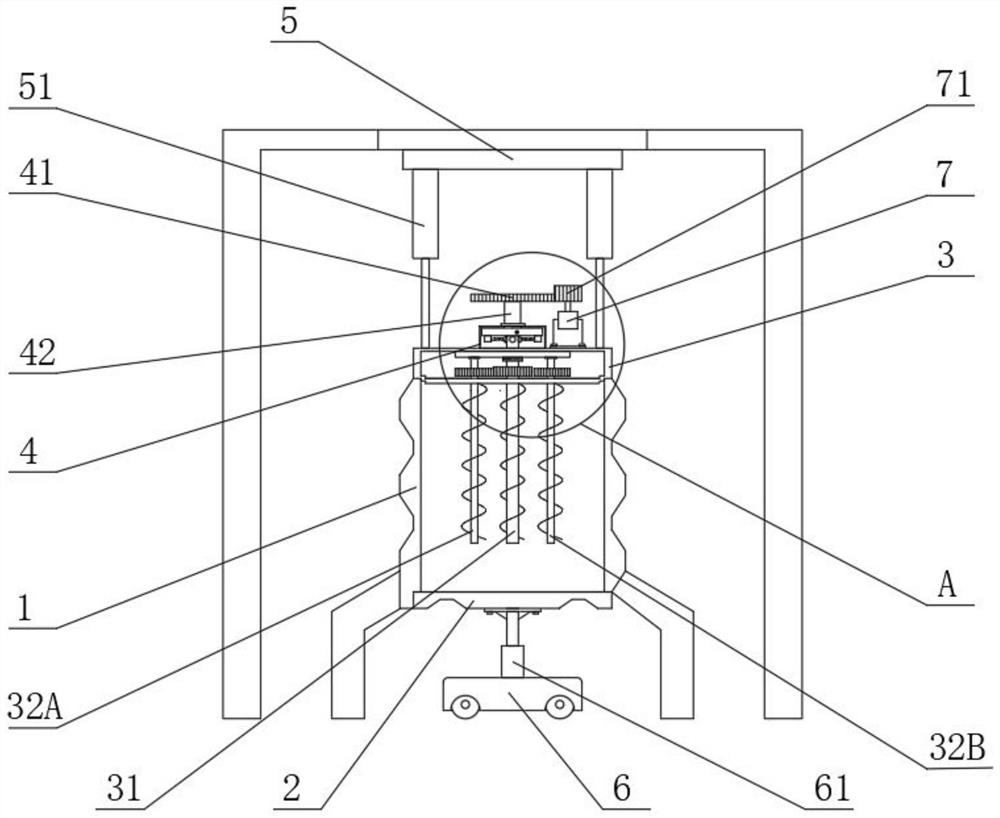

[0040] Embodiment 2: a kind of method using above-mentioned constant moment concrete mixer to stir concrete, comprises the steps:

[0041] Step 1: Put concrete of various types and proportions into the mixing tank 1 for stirring, and judge the viscosity of the concrete slurry by monitoring the output torque and rotational speed of the motor 7 during the stirring process, and record it as a database;

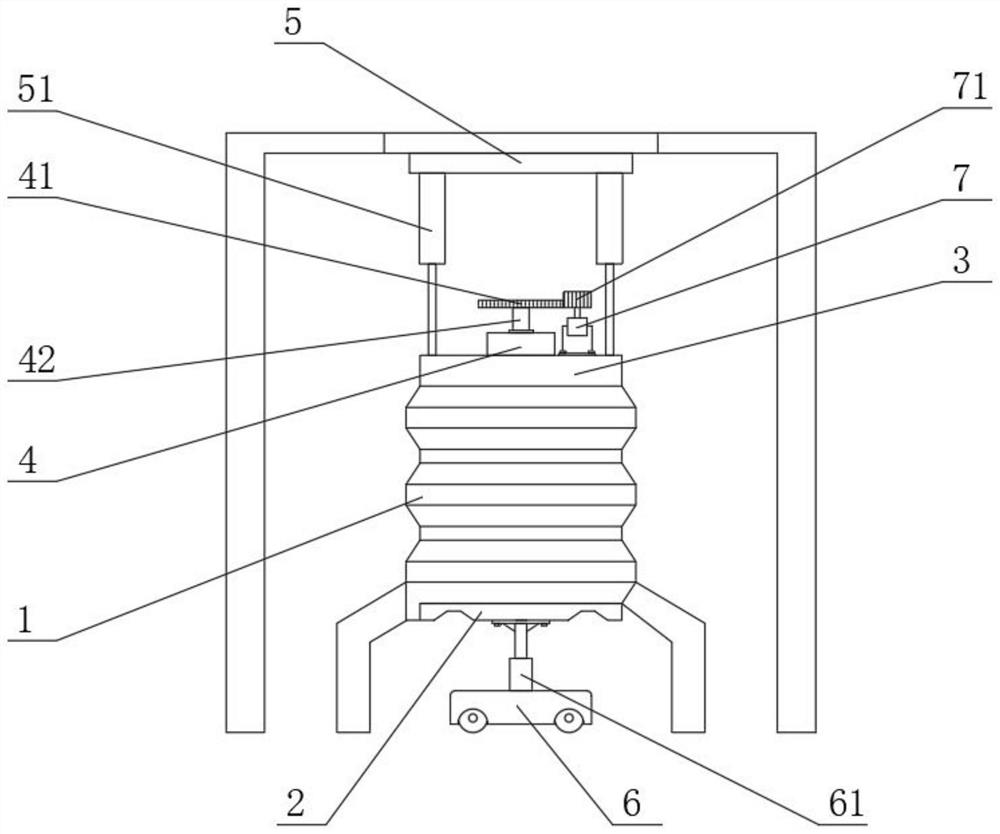

[0042] Step 2: Fit the bottom cover 2 to the bottom of the mixing tank 1 through the bottom trolley 6 and the lifting rod 61 and seal it well;

[0043] Step 3: Lift the mixing cover 3 from the top of the mixing tank 1 through the lifting rod 51;

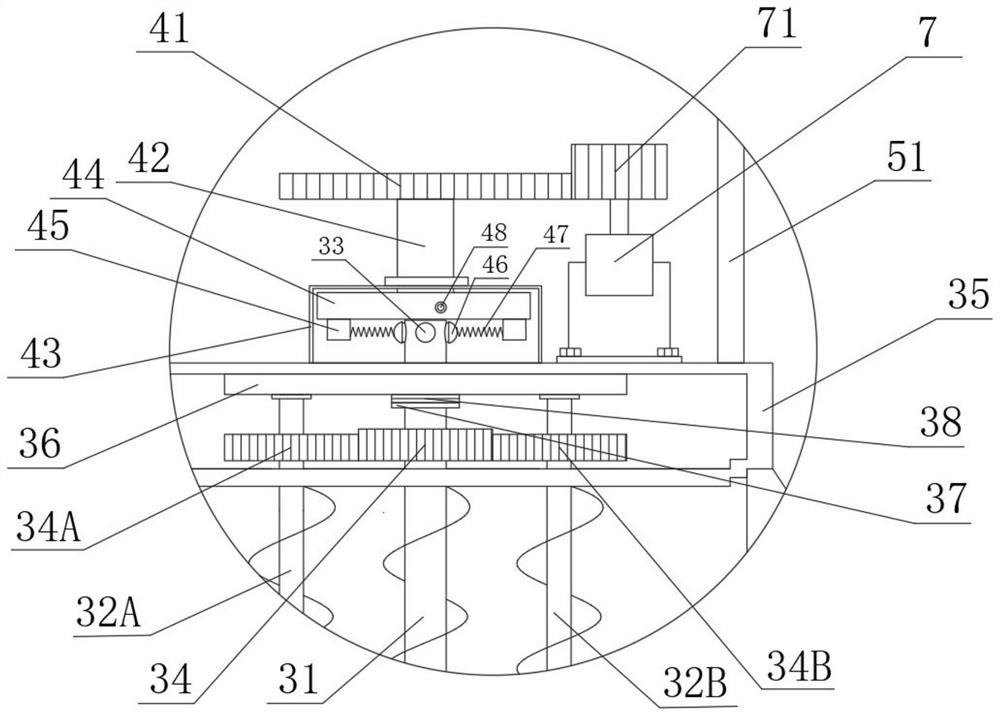

[0044] Step 4: Rotate the claw plate adjustment knob 48 to adjust the distance between the joint hemisphere 46 and the claw 45 until the maximum rotational torque between the four-jaw chuck 44 and the main stirring rod 31 meets the required torque requirement;

[0045] Step 5: Start the motor 7 for stirring. During the stirring process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com