Internal expansion type steel pipe pile for extra-long steel trestle in complex sea area environment

A technology for steel pipe piles and steel trestle bridges, which can be used in sheet pile walls, buildings, infrastructure projects, etc., and can solve problems such as affecting the stability of steel pipe piles and shaking concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

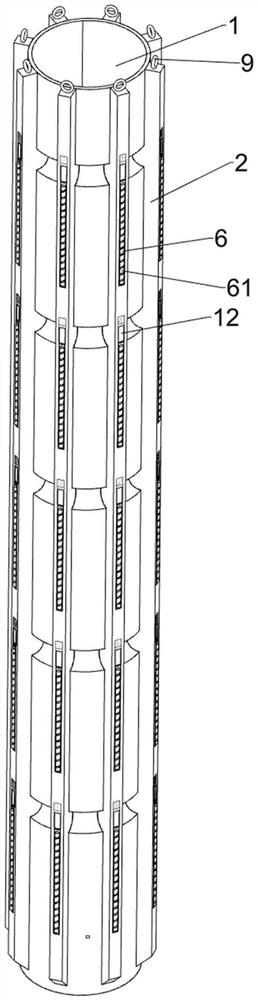

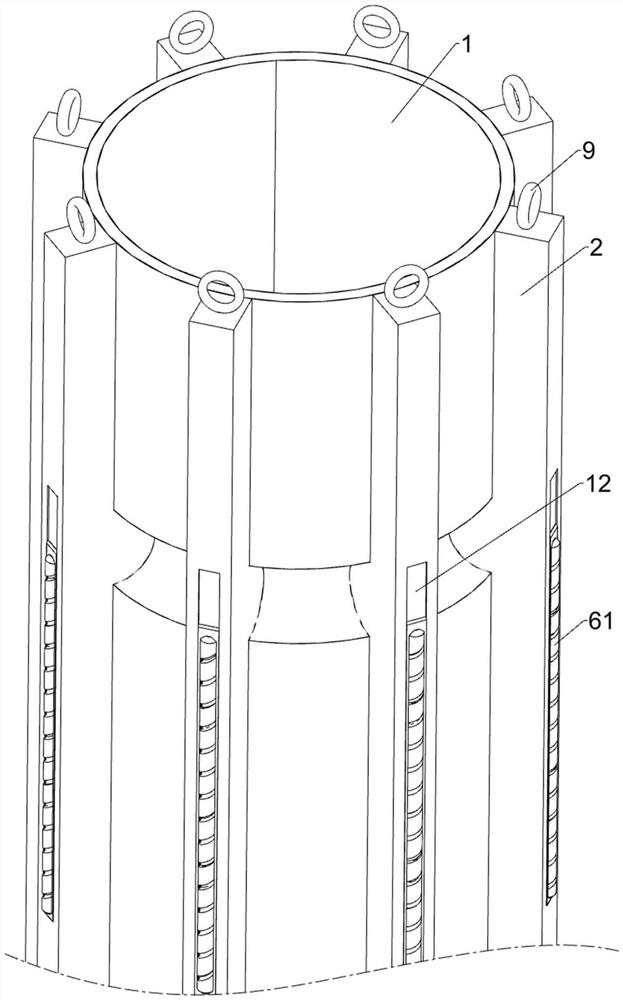

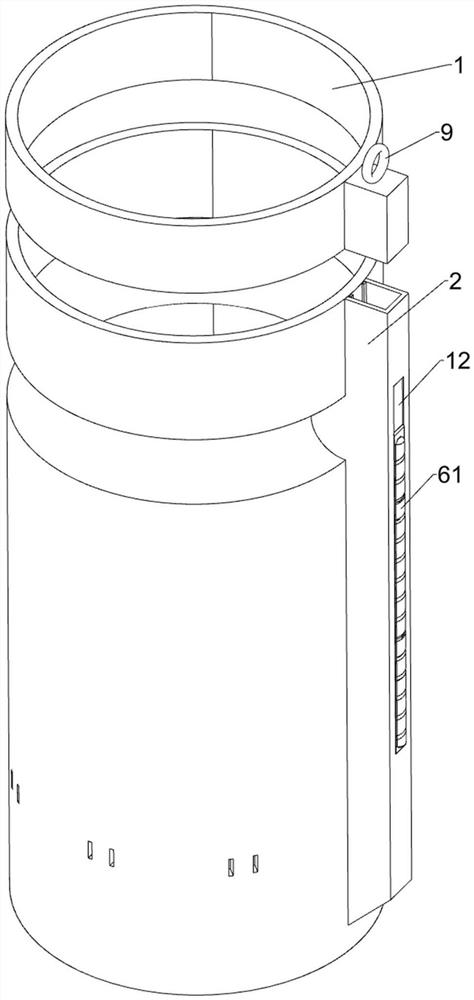

[0035] Embodiment: An internally expanded steel pipe pile for extra-long steel trestle bridges in complex sea environment.

[0036] refer to Figure 1-Figure 5 As shown, it includes a steel pipe pile 1, a shell 2, a hollow circular block 3, a driving mechanism 4 and a clamping mechanism 5. Eight shells 2 are fixedly connected to the outer wall of the steel pipe pile 1 at even intervals, and inside the shell 2 A clamping mechanism 5 is provided, and a driving mechanism 4 is provided between the casing 2 and the lower part of the steel pipe pile 1. The driving mechanism 4 is in contact with the clamping mechanism 5, and a hollow circular block is placed slidingly on the inner lower part of the steel pipe pile 1. 3. The outer bottom of the hollow circular block 3 is connected and matched with the driving mechanism 4 .

[0037] The driving mechanism 4 includes special-shaped rods 41, L-shaped rods 42 and tooth blocks 43. Sixteen L-shaped rods 42 are evenly spaced slidingly throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com