Precast concrete pile

A technology of prefabricated concrete and concrete layers, which is applied in sheet pile walls, buildings, and foundation structure engineering. It can solve problems such as joint damage, welding defects, and corrosion, and achieve increased strength, improved bending resistance, and simple and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

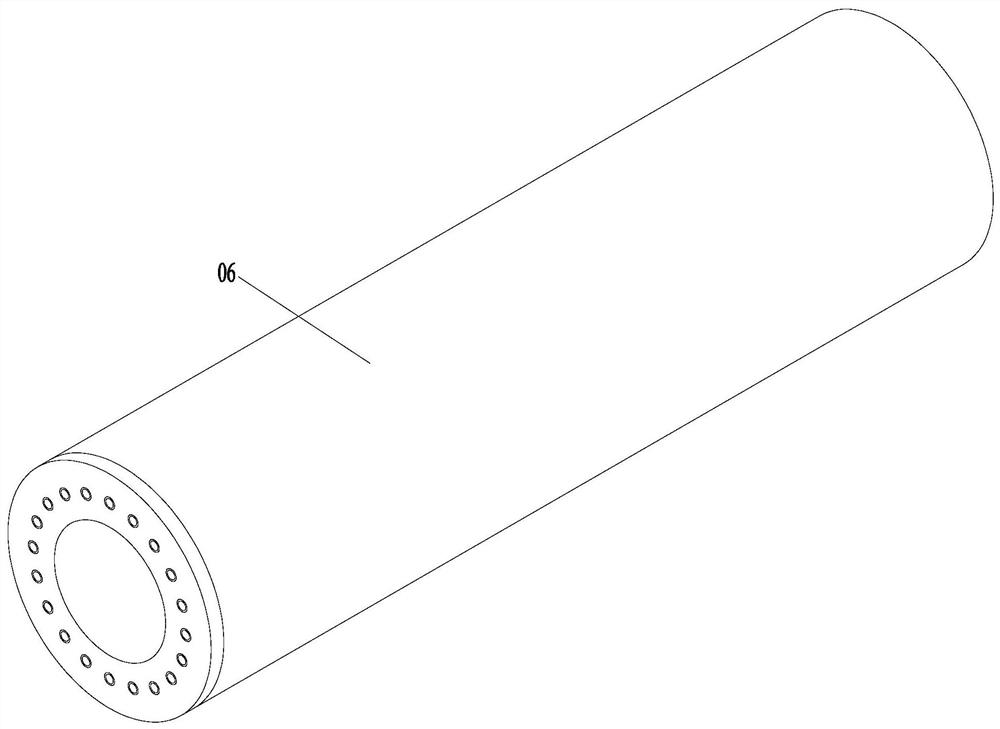

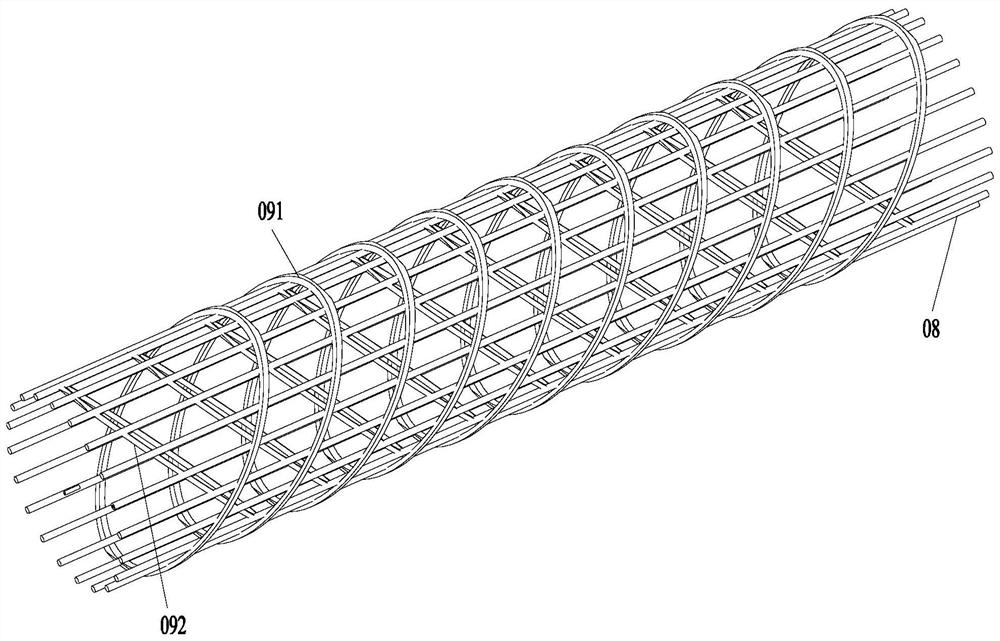

[0044] Such as Figure 1 to Figure 4 As shown, the present invention provides a prefabricated concrete pile, including a skeleton layer and a concrete layer 06, and the skeleton layer includes several steel bars 08 uniformly distributed along the circumferential direction, several first annular bodies 091 uniformly distributed along the axial direction and several A second ring body 092 uniformly distributed along the axial direction;

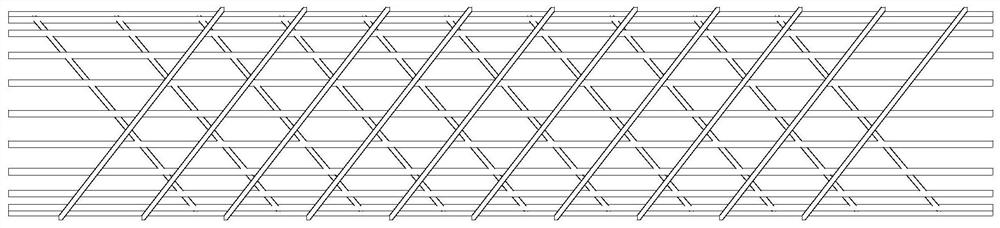

[0045] The first ring body 091 is wrapped on the steel bar 08, and the steel bar 08 is wrapped on the second ring body 092, and the inclination direction of the first ring body 091 and the second ring body 092 is opposite (as image 3 As shown, one is tilted to the left and one is tilted to the right); that is, as figure 2 As shown, the first ring body 091 is wrapped on the ring-shaped outer ring formed by the steel bar 08 and fixed to it to form multiple fixed points, while the second ring body 092 is embedded in the ring-shaped inner ring for...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap