An anti-cross-cavity structure between parallel flow channels

A cavity structure, anti-string technology, applied in the field of the cooling plate structure of the combustion chamber, can solve the problems of affecting the performance, reducing the cooling effect of the combustion chamber, and small brazing area, so as to increase the brazing area, improve the cooling performance, and avoid the medium The effect of the string cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

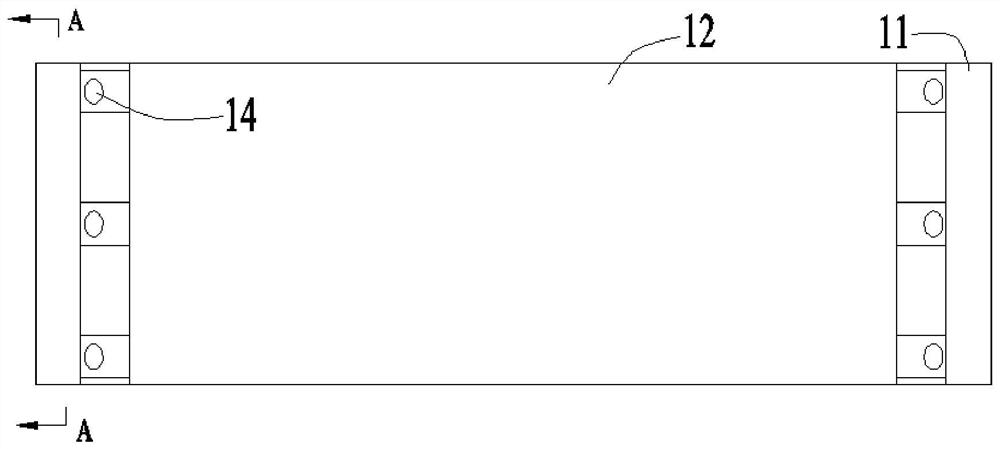

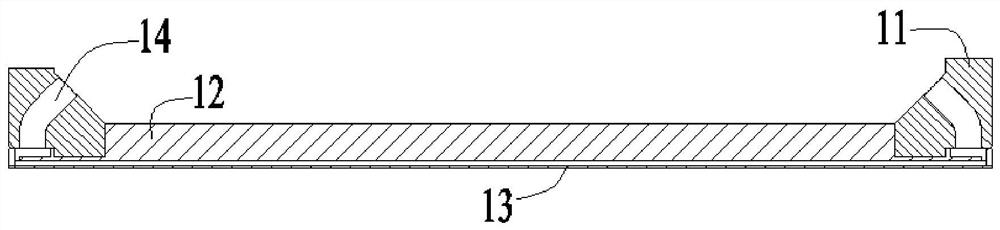

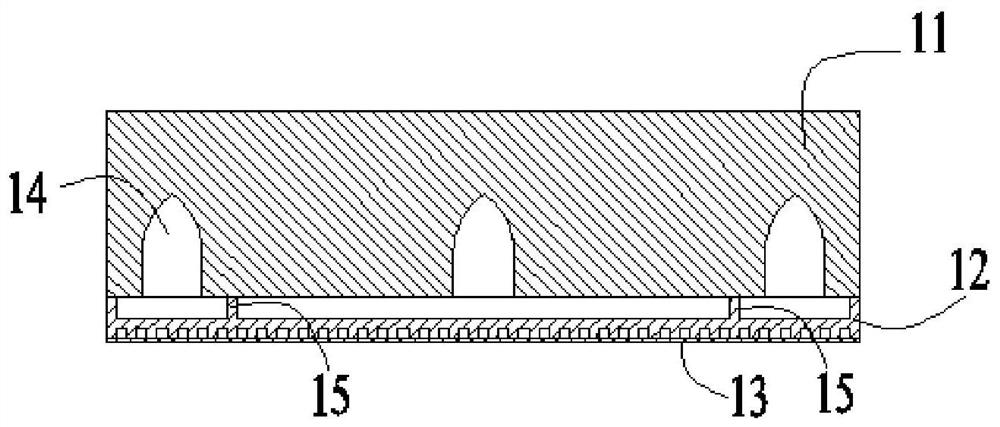

[0027] The invention discloses an anti-cross-cavity structure between parallel flow channels, such as Figure 4 As shown, it includes a base plate 12, the top surface of the base plate 12 is connected with a flange 11, and the bottom surface of the base plate 12 is connected with a cover plate 13; there are several cavities 14 between the flange 11 and the top surface of the base plate 12; the bottom of the flange 11 A number of strip-shaped grooves are opened; the top surface of the base plate 12 is extended with a number of second compartment plates 152, the second compartment plates 152 and the strip-shaped grooves of the flange 11 have the same number and corresponding positions, and the second compartment plate 152 The height of the cavity plate 152 is greater than the first distance, and the first distance is the distance between the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com