Automobile all-aluminum intercooler

A technology for automobiles and coolers, which is applied to machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve the problems of difficult positioning of the side plates of the intercooler, affecting assembly efficiency, and low success rate, so as to improve assembly production efficiency, Guarantee the qualification rate of brazing and the effect of product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

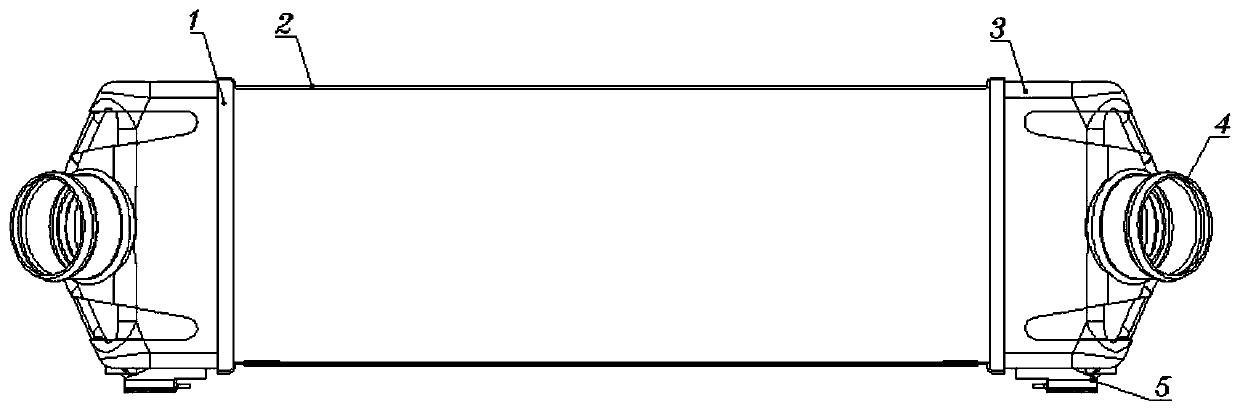

[0038] A kind of automobile all-aluminum intercooler, such as figure 1 As shown, it includes a core body and air chambers 3 connected to both ends of the core body. The core body includes a main sheet 1 and a side plate 2 connected to the main sheet 1. The common heat exchange mechanisms in the core body are heat exchange tubes, heat dissipation Tubes and turbulence belts, the all-aluminum intercooler of the automobile are fixed on the automobile body through the bracket 5, and the bracket 5 is arranged on the air chamber 3; .

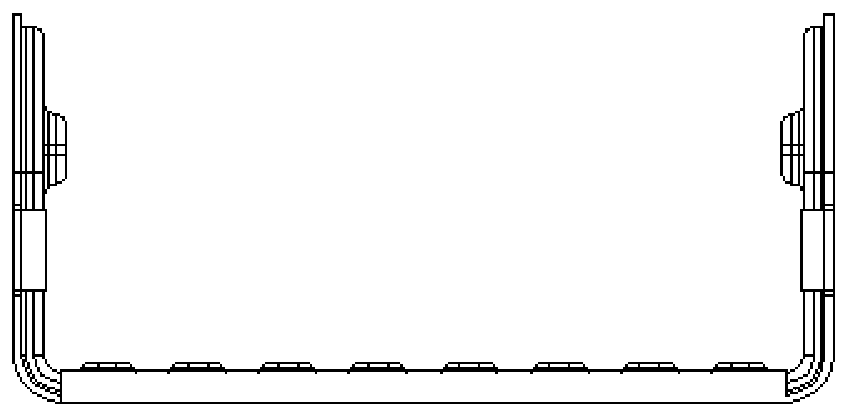

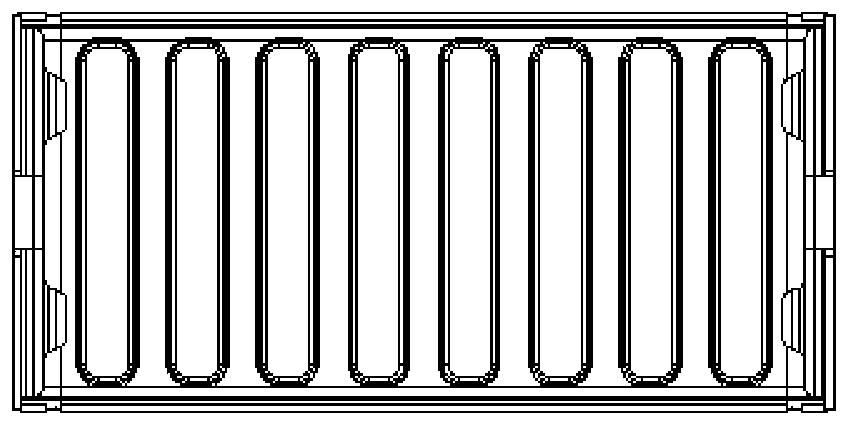

[0039] The first is to improve the structure of the main piece 1. The existing main piece includes the main piece body and connecting parts on both sides, such as figure 2 and image 3 As shown, the connecting parts on both sides are matched with the air chamber to realize the fixing and sealing of the main piece and the air chamber. In this embodiment, the main sheet 1 includes a main sheet body and a flange structure 11 arranged around the main s...

Embodiment 2

[0045] A kind of automobile all-aluminum intercooler, such as figure 1 As shown, it includes a core body and air chambers 3 connected to both ends of the core body. The core body includes a main sheet 1 and a side plate 2 connected to the main sheet 1. The common heat exchange mechanisms in the core body are heat exchange tubes, heat dissipation Tubes and turbulence belts, the all-aluminum intercooler of the automobile are fixed on the automobile body through the bracket 5, and the bracket 5 is arranged on the air chamber 3; .

[0046] The first is to improve the structure of the main piece 1. The existing main piece includes the main piece body and connecting parts on both sides, such as figure 2 with image 3 As shown, the connecting parts on both sides are matched with the air chamber to realize the fixing and sealing of the main piece and the air chamber. In this embodiment, the main sheet 1 includes a main sheet body and a flange structure 11 arranged around the main sh...

Embodiment 3

[0050] A kind of automobile all-aluminum intercooler, such as figure 1 As shown, it includes a core body and air chambers 3 connected to both ends of the core body. The core body includes a main sheet 1 and a side plate 2 connected to the main sheet 1. The common heat exchange mechanisms in the core body are heat exchange tubes, heat dissipation Tubes and turbulence belts, the all-aluminum intercooler of the automobile are fixed on the automobile body through the bracket 5, and the bracket 5 is arranged on the air chamber 3; .

[0051] The first is to improve the structure of the main piece 1. The existing main piece includes the main piece body and connecting parts on both sides, such as figure 2 with image 3 As shown, the connecting parts on both sides are matched with the air chamber to realize the fixing and sealing of the main piece and the air chamber. In this embodiment, the main sheet 1 includes a main sheet body and a flange structure 11 arranged around the main ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Step height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com