A Whole Welding Method of Complicated Rectangular Nozzle

A rectangular nozzle and welding method technology, applied in welding equipment, manufacturing tools, auxiliary devices, etc., can solve the problems of unguaranteed brazing surface sealing, difficult tooling clamping, high tooling requirements, and reduce brazing. Difficulty, reduce processing difficulty, increase the effect of brazing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

[0029] A method for integrally welding complex rectangular nozzles, comprising the following steps:

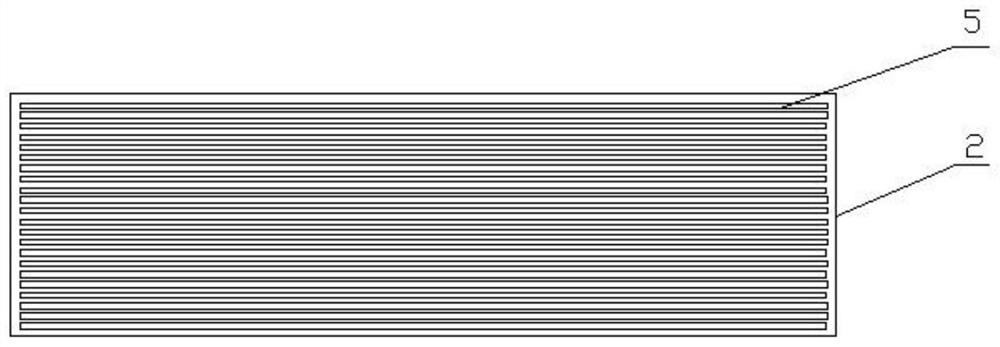

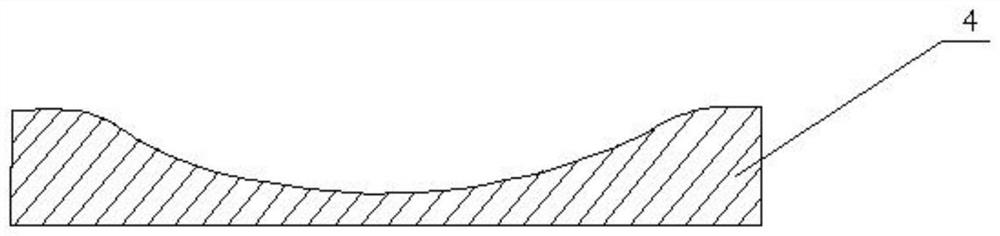

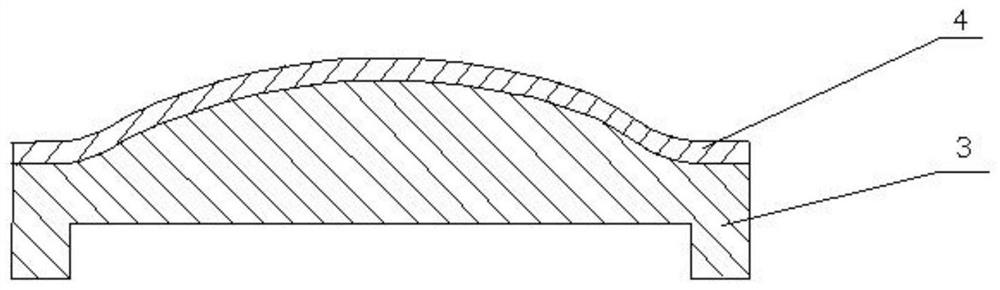

[0030] (1) According to the design requirements of the complex rectangular nozzle to be processed, vacuum brazing is carried out after it is manufactured separately according to the four-part assembly; wherein, the four-part assembly includes a symmetrical left assembly 6 and a right assembly 7, and The symmetrical upper assembly 8 and the lower assembly 9; the left assembly 6 and the right assembly 7 both include a first stainless steel substrate 1 and a first copper plate 2 with a cooling channel 5 on one side; the upper assembly 8 and the lower assembly 9 both include A second stainless steel substrate 3 with a curved surface and a second copper plate 4 that can be bonded to it, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com