Amorphous alloy brazing method and device

A technology of amorphous alloy and brazing method, applied in auxiliary devices, metal processing, welding equipment, etc., can solve the problems of inconsistent performance, unstable performance and incomplete welding of amorphous alloy, achieve stable performance, reduce brazing Difficulty, the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

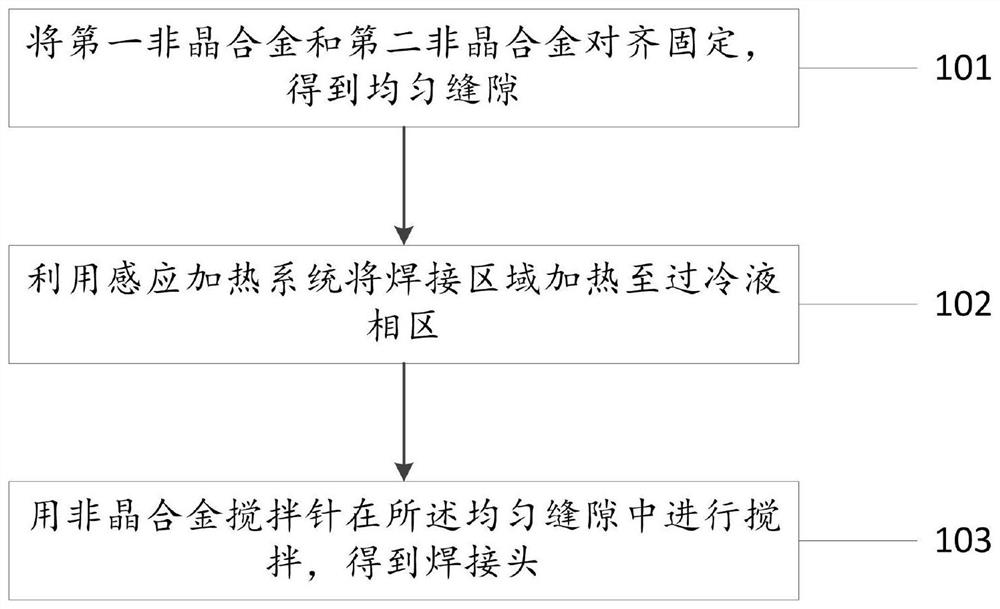

[0046] figure 1 It is a schematic flow chart of the amorphous alloy brazing method shown in the embodiment of the present application.

[0047] see figure 1 , the amorphous alloy brazing method specifically includes:

[0048] 101. Align and fix the first amorphous alloy and the second amorphous alloy to obtain a uniform gap;

[0049] The uniform gap is a uniform gap between the first amorphous alloy and the second amorphous alloy.

[0050] The first amorphous alloy and the second amorphous alloy are two pieces of amorphous alloy to be welded.

[0051] In the embodiment of the present application, the welding of two rectangular parallelepiped amorphous alloys of the same size is taken as an example. A gap is reserved between the two amorphous alloys, and the width of the gap is equal everywhere, that is, a uniform gap. After the alignment of the space, the amorphous alloy is fixed to ensure that the amorphous alloy does not shift and the uniform gap exists stably. It shoul...

Embodiment 2

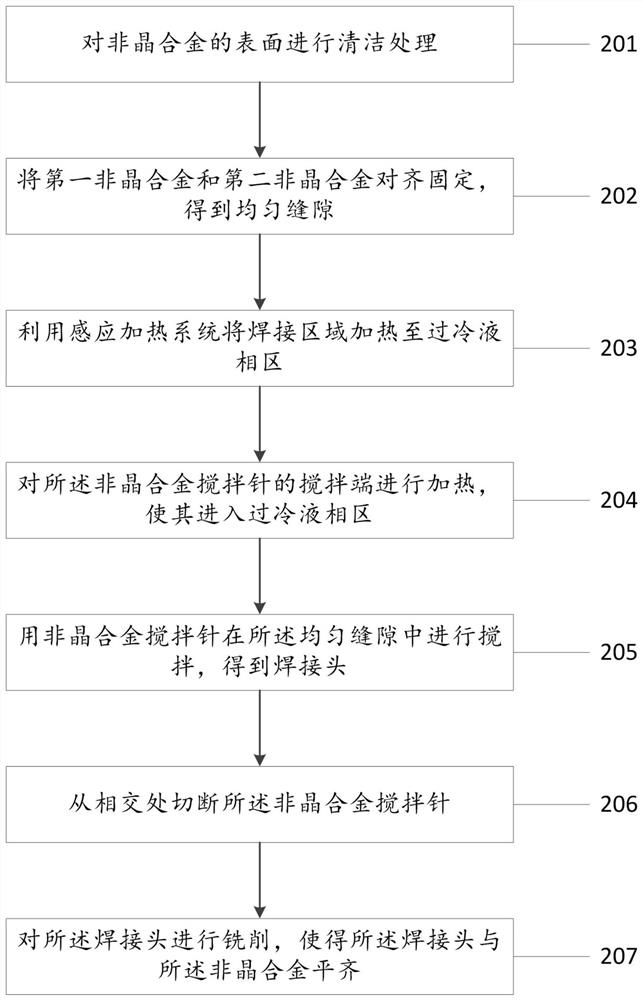

[0062] This embodiment provides an amorphous alloy brazing method. Compared with the previous embodiment, this embodiment further optimizes and perfects the method, such as figure 2 As shown, the amorphous alloy brazing method specifically includes:

[0063] 201. Cleaning the surface of the amorphous alloy;

[0064] The cleaning treatment specifically includes: grinding the surface of the amorphous alloy, cleaning the amorphous alloy and drying the amorphous alloy.

[0065] The cleaning of the amorphous alloy includes: placing the amorphous alloy in acetone, ethanol and clear water in sequence for ultrasonic cleaning.

[0066] The time for the amorphous alloy to be placed in acetone and ethanol for ultrasonic cleaning is 5 minutes.

[0067] The drying the amorphous alloy includes placing the amorphous alloy in an argon chamber for drying.

[0068] In the embodiment of the present application, the pollutants such as oxides on the surface of the amorphous alloy are first pol...

Embodiment 3

[0086] Corresponding to the aforementioned embodiment of the method for realizing the application function, this embodiment provides an amorphous alloy brazing device and corresponding embodiments.

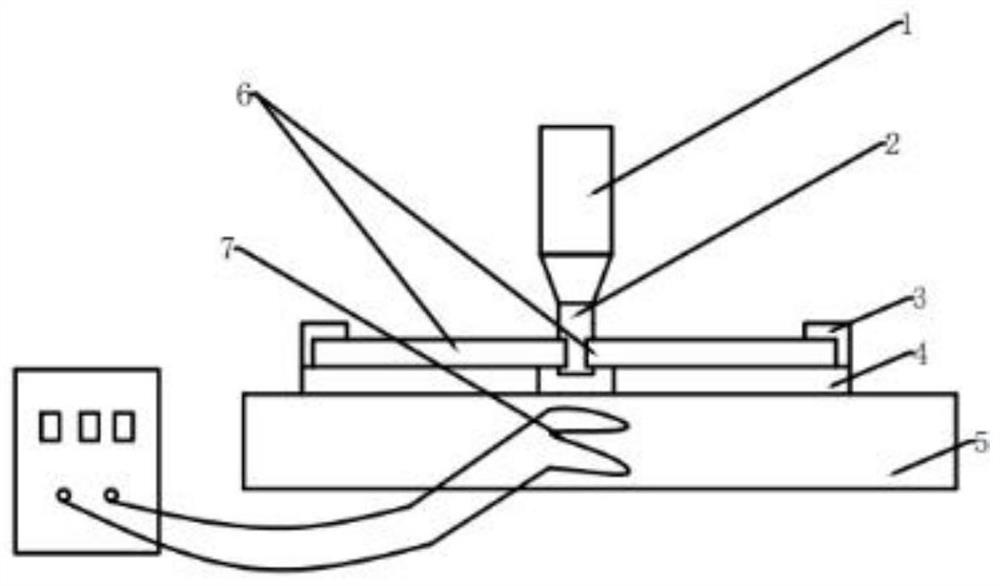

[0087] image 3 It is a structural schematic diagram of the amorphous alloy brazing device shown in the embodiment of the present application.

[0088] see image 3 , the amorphous alloy brazing device specifically includes:

[0089] Motor 1, amorphous alloy stirring needle 2, fixing fixture 3, stage 4, workbench 5 and induction heating system 7; the induction heating system is connected to the workbench and heats the welding area of amorphous alloy 6; on the workbench There are two stages for carrying the amorphous alloy, and there is a stirring gap between the stages; the edge of the stage is provided with a fixing fixture for fixing the amorphous alloy; the first amorphous alloy to be welded and the second The two amorphous alloys are respectively placed on two stages, ali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com