Method for manufacturing air bag, air bag, and seat device for vehicle

A manufacturing method and air bag technology, which can be applied to vehicle seats, special positions of vehicles, vehicle parts, etc., can solve problems such as fractures in peripheral parts, and achieve the effect of improving durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, an embodiment of an air bag and a vehicle seat device will be described with reference to the drawings.

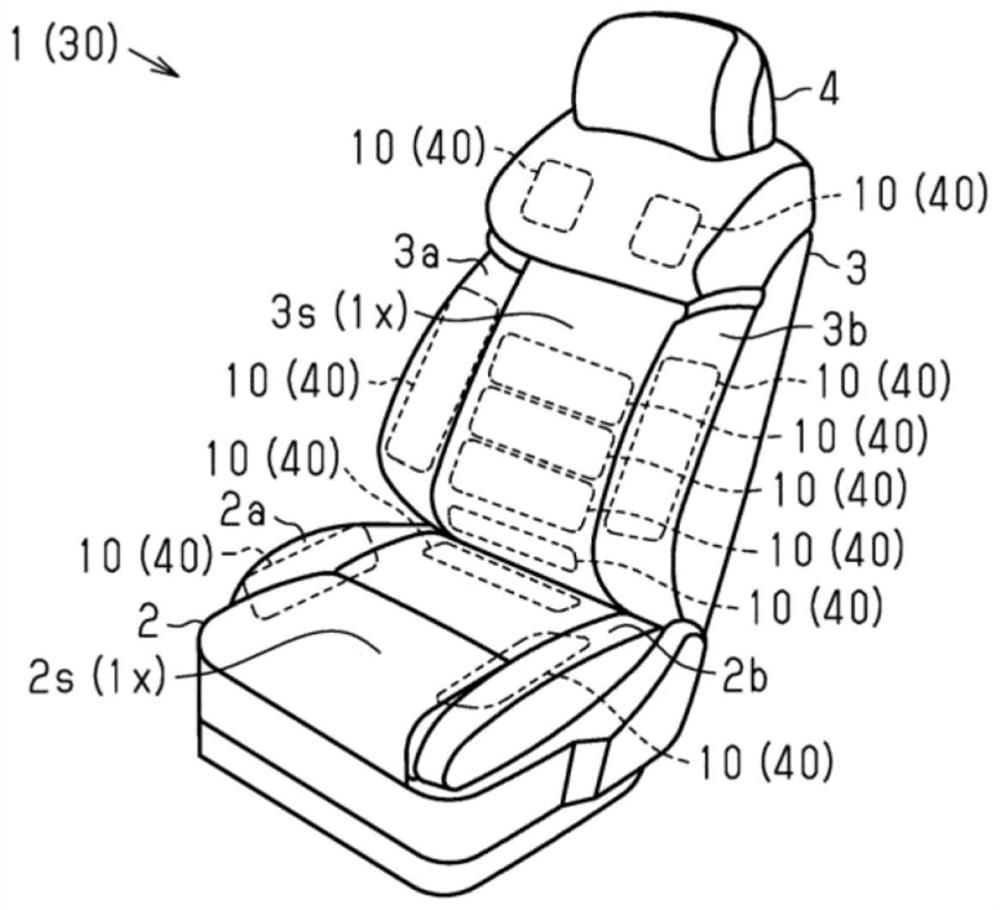

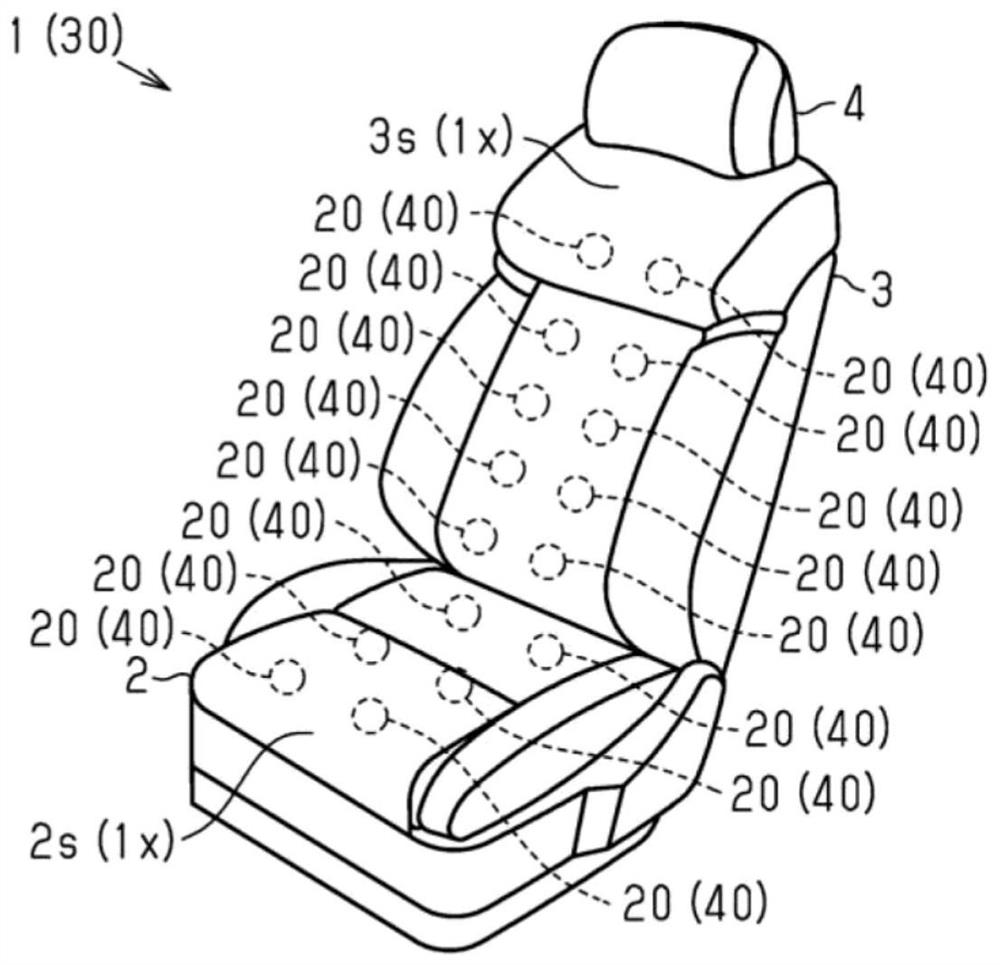

[0049] Such as figure 1 and figure 2 As shown, a vehicle seat 1 includes a seat cushion 2 and a seat back 3 provided at a rear end portion of the seat cushion 2 . Furthermore, a headrest 4 is provided on the upper end of the seat back 3 .

[0050] In addition, in the seat 1 of the present embodiment, the seat back 3 has a shape in which both side portions 3a, 3b are respectively swollen toward the front. Furthermore, the seat cushion 2 also has a shape in which both side parts 2a and 2b bulge upward, respectively. Then, the seat 1 of the present embodiment thereby becomes capable of securing a good sitting posture of the occupant and maintaining the sitting posture.

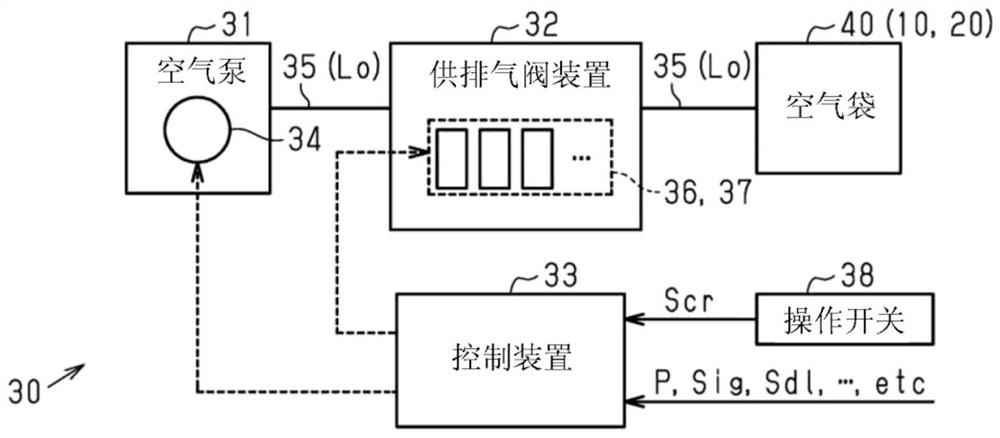

[0051] In addition, the seat 1 is provided with a plurality of air bags 10 that expand and contract inside the seat cushion 2 and the seat back 3 to change the supporting shape of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com