Break-resistant transfer device based on glass production

A transfer device, anti-rupture technology, applied in the directions of transportation and packaging, trolley accessories, multi-axis trolleys, etc., can solve the problem of not being able to automatically place glass sheets in the transfer device, and achieve the effect of reducing vibration and preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

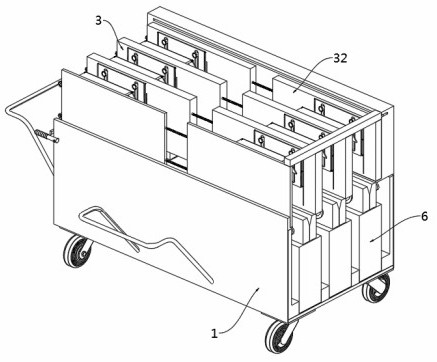

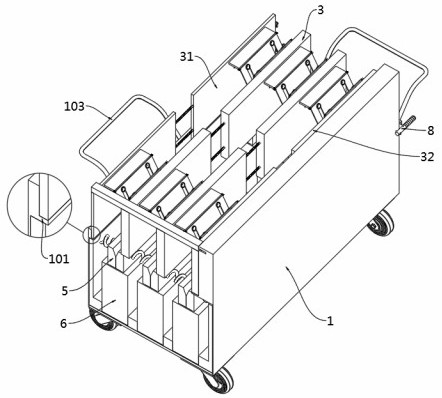

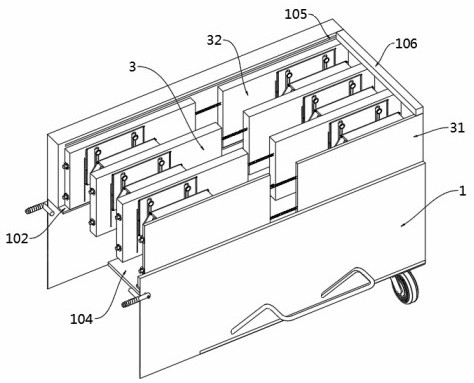

[0036] Embodiment one: as attached figure 1 to attach Figure 12 As shown: the present invention provides an anti-crack protective transfer device based on glass production, including a transfer vehicle; the transfer vehicle includes: an outer transfer vehicle 1 and an inner transfer vehicle 2; A placement mechanism 3 is installed on the inside of 1, and a controller is installed inside the outer transfer car 1, the inner front side is fixedly connected to the supporting plate 101, and the inner rear side is fixedly connected to the fixed plate 102, and the front and rear sides of the outer transfer car 1 are respectively moved through shafts. Connect the lock bar 8; the bottom of the inner transfer vehicle 2 is movably connected to the protective member 6, and the top of the inner left side of the inner transfer vehicle 2 is fixedly connected to the block 9; the placement mechanism 3 includes a placement device 31 and an auxiliary device 32, and the placement mechanism 3 It ...

Embodiment 2

[0046] Embodiment 2: On the basis of Embodiment 1, when the placement device 31 drives the glass to rotate downwards to the vertical state and the glass fits the straight suction cup 3205, the signal is transmitted to the controller through the induction loop (this process is the same as that of Embodiment 1 The same, no more details), the controller sends an instruction after receiving the signal to make the straight suction cup 3205 start to work, after the straight suction cup 3205 sucks the glass, the controller controls the rotating suction cup 3104 to stop working, and at the same time controls the electric track 3202 to start working, such as the straight suction cup 3205 In the starting state, the straight suction cup 3205 is located at the top of the auxiliary plate 3204 slot, then the straight suction cup 3205 will move downward under the influence of gravity, the electric track 3202 drives the moving rod 3203 to move downward, and the moving rod 3203 drives the auxili...

Embodiment 3

[0047]Embodiment 3: On the basis of Embodiment 1, a protective net or a rainproof film can be added, and a round hole is added on the outer edge and penetrated by a rope. The adjustment rod 4 can be replaced by a hydraulic rod and the end is fixedly connected to a group of auxiliary components on the right side. The device 32 has other structures unchanged. When the distance of the placement mechanism 3 needs to be adjusted, it is only necessary to adjust the hydraulic lever to push a group of auxiliary devices 32 on the right side to move, and then drive the placement mechanism 3 to move. When the glass is filled with the transfer car, pass The clamping rod 802 is clamped with the clamping block 9, and then the protective net or rainproof film is placed on the top of the transfer vehicle, and then fixed on the main main handle 103 and the auxiliary handle 201 by a rope, so that the entire transfer vehicle is in a fully wrapped state , During the transfer process, if an acciden...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com