Pixel sharing-based PWM driving circuit and driving method

A driving circuit and driving method technology, applied in the direction of electrical components, instruments, static indicators, etc., can solve the problems of high process stability and quality requirements, a large number of transistors, high manufacturing costs, etc., and achieve the drive area and resolution. Effects of limitation, reduction in transistor count, and reduction in manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

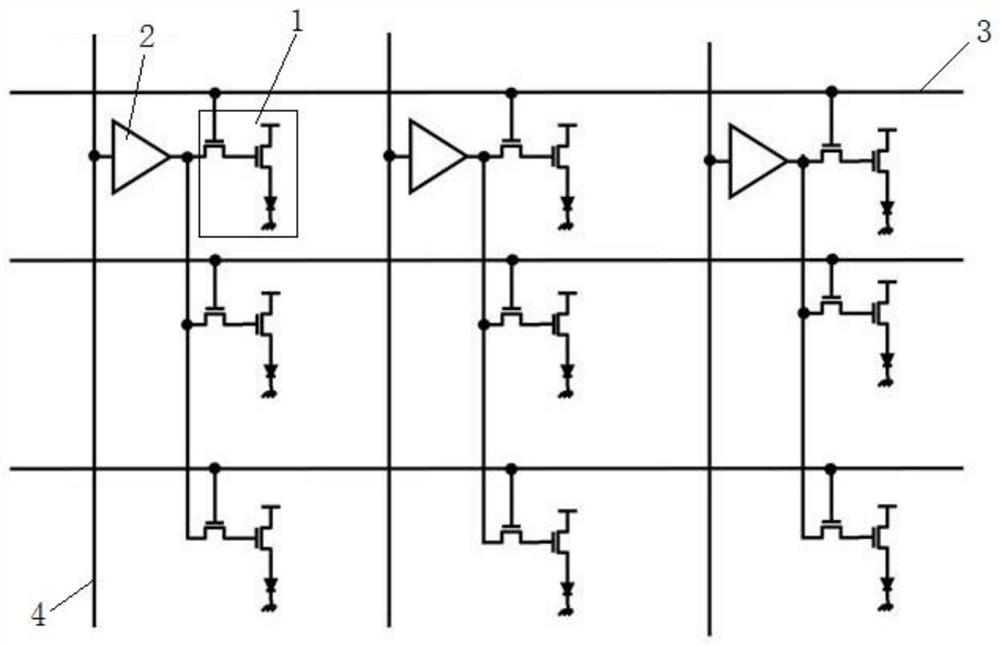

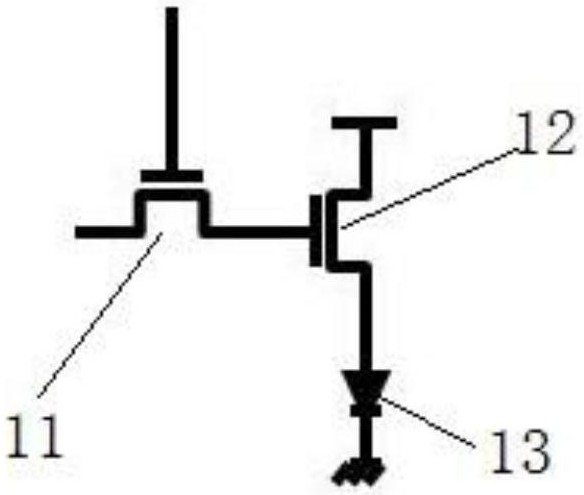

[0031] see figure 1 The shown PWM drive circuit based on pixel sharing includes light-emitting units 1 arranged in a rectangular array; corresponding to each column of light-emitting units 1, it also includes a signal processing module 2 and a second signal connected to the signal processing module 2 Transmitter 4, any light-emitting unit 1 in each column is signal-connected to signal processing module 2; corresponding to each row of light-emitting units 1, it also includes a first signal transmitter 3, any light-emitting unit 1 in each row is connected to the first signal transmitter 1 signal connection.

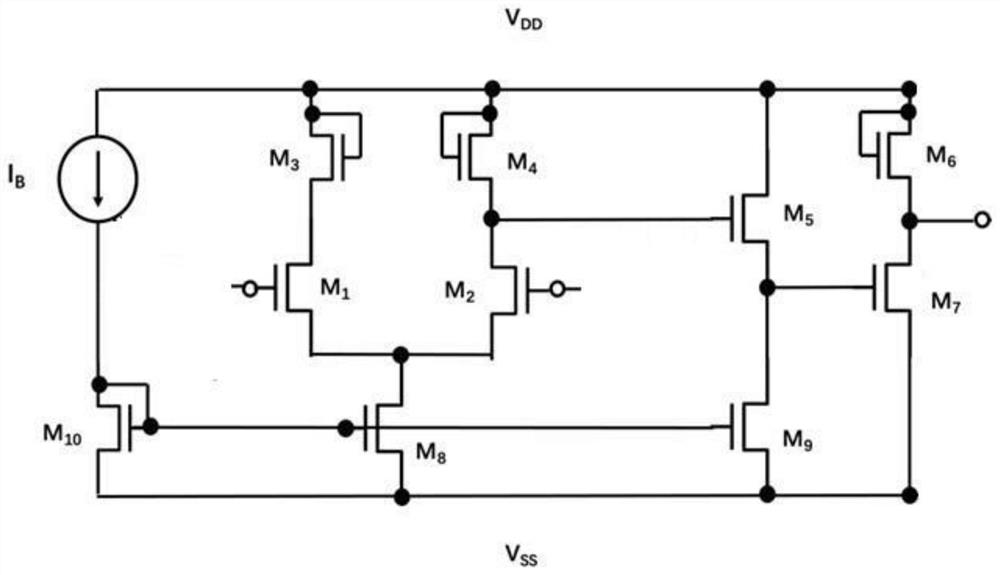

[0032] Wherein, the signal processing module 2 is a module shared by columns, the second signal transmitter 4 provides signals for the signal processing module 2, and the signal processing module 2 can provide driving signals for all light-emitting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com