Environment-friendly construction waste crusher

A construction waste and pulverizer technology, applied in grain processing and other directions, can solve the problems of insufficient technology, reduce the counterattack force of the counterattack plate, and unfavorable scrap discharge, so as to improve the crushing effect and efficiency, reduce the recoil force and vibration force, reduce the Effects of mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

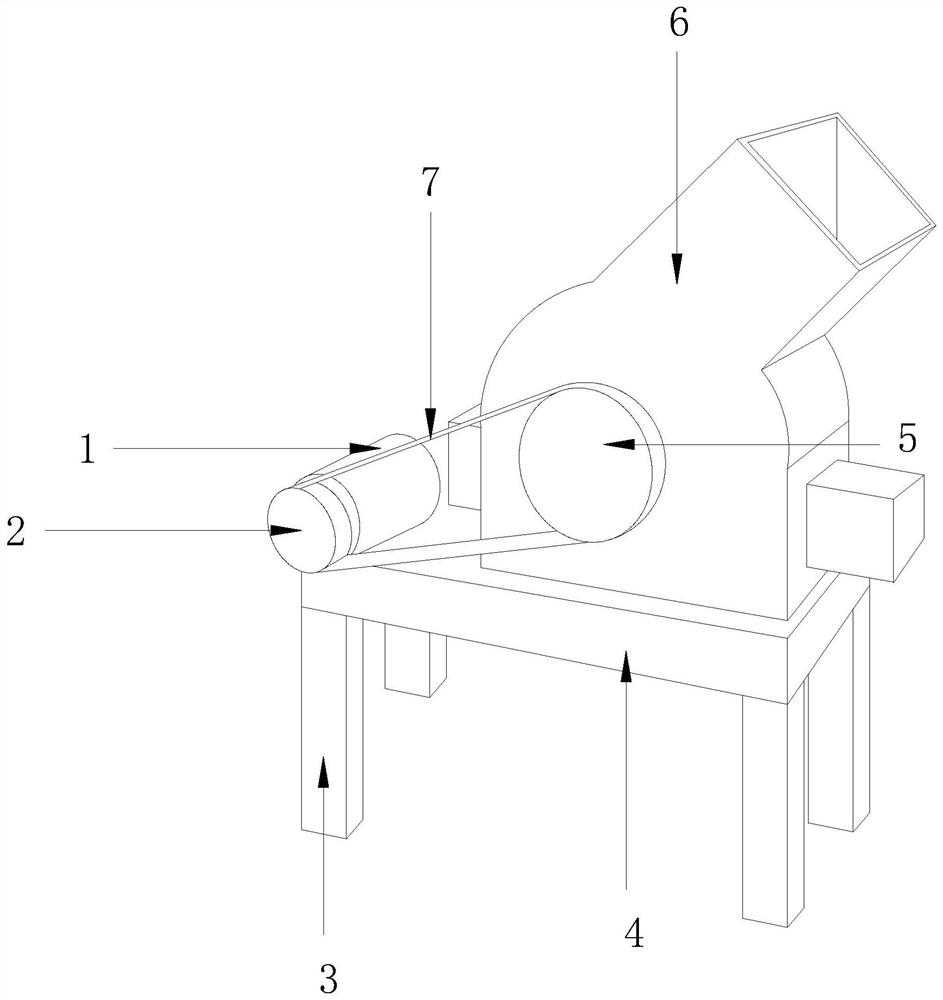

[0028] Such as figure 1 As shown, the present invention provides a technical solution of an environmentally friendly construction waste shredder: its structure includes a motor 1, a first transmission wheel 2, a supporting foot column 3, a base 4, a second transmission wheel 5, a shredder 6, and a transmission belt 7. A base 4 is installed on the top of the supporting foot column 3, and a motor 1 is provided on one side of the top of the base 4, and the shaft of the motor 1 is connected with the first transmission wheel 2, and the first transmission wheel 2 Via the transmission belt 7 and the second transmission wheel 5, the second transmission wheel 5 is connected with the pulverizer 6.

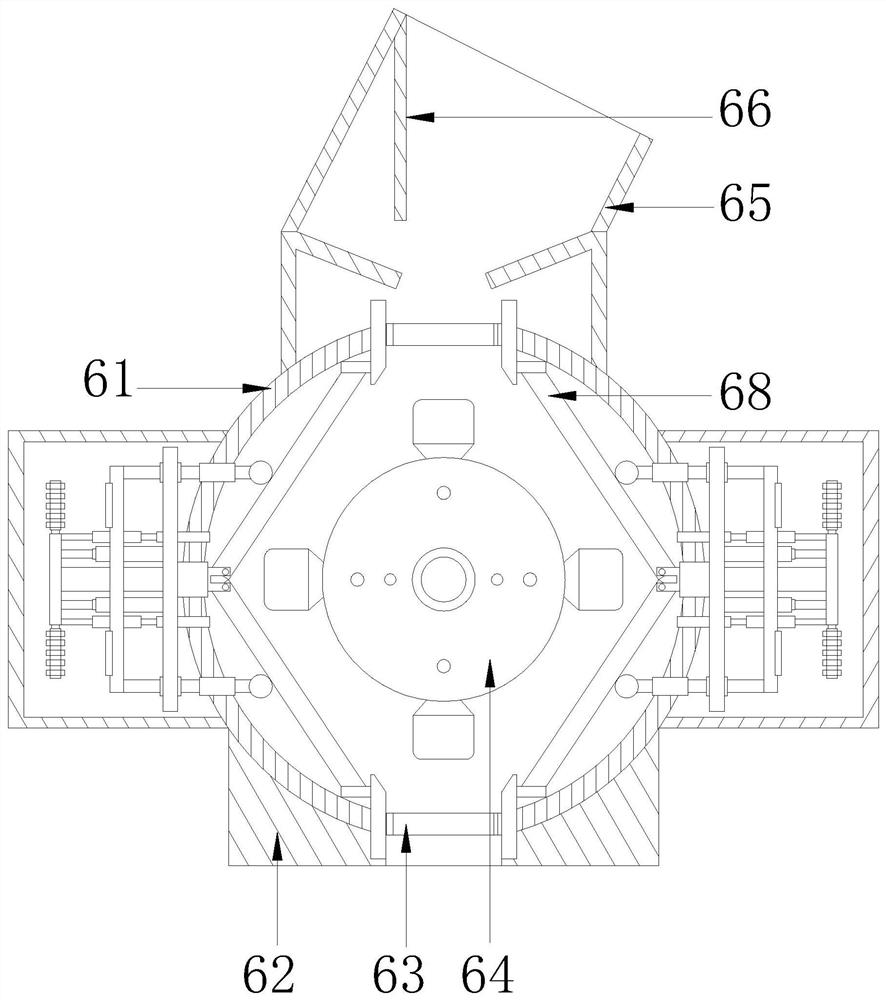

[0029] Such as Figure 2-3As shown, the pulverizer 6 includes a counterattack material frame 61, a pulverizer shell 62, a sieve plate 63, a crushing device 64, a feed port 65, a baffle plate 66, and a chute plate 67. There is a pulverizing device 64, and a sieve plate 63 is arranged below...

Embodiment 2

[0035] Such as Figure 1-Figure 8 As shown, the present invention provides a technical solution of an environmentally friendly construction waste shredder: its structure includes a motor 1, a first transmission wheel 2, a supporting foot column 3, a base 4, a second transmission wheel 5, a shredder 6, and a transmission belt 7. A base 4 is installed on the top of the supporting foot column 3, and a motor 1 is provided on one side of the top of the base 4, and the shaft of the motor 1 is connected with the first transmission wheel 2, and the first transmission wheel 2 Via the transmission belt 7 and the second transmission wheel 5, the second transmission wheel 5 is connected with the pulverizer 6.

[0036] The pulverizer 6 includes a counterattack material frame 61, a pulverizer shell 62, a sieve plate 63, a pulverizing device 64, a feed port 65, a baffle plate 66, and a chute plate 67, and the pulverizer shell 62 is provided with a pulverizing device. 64. A sieve plate 63 is...

Embodiment 3

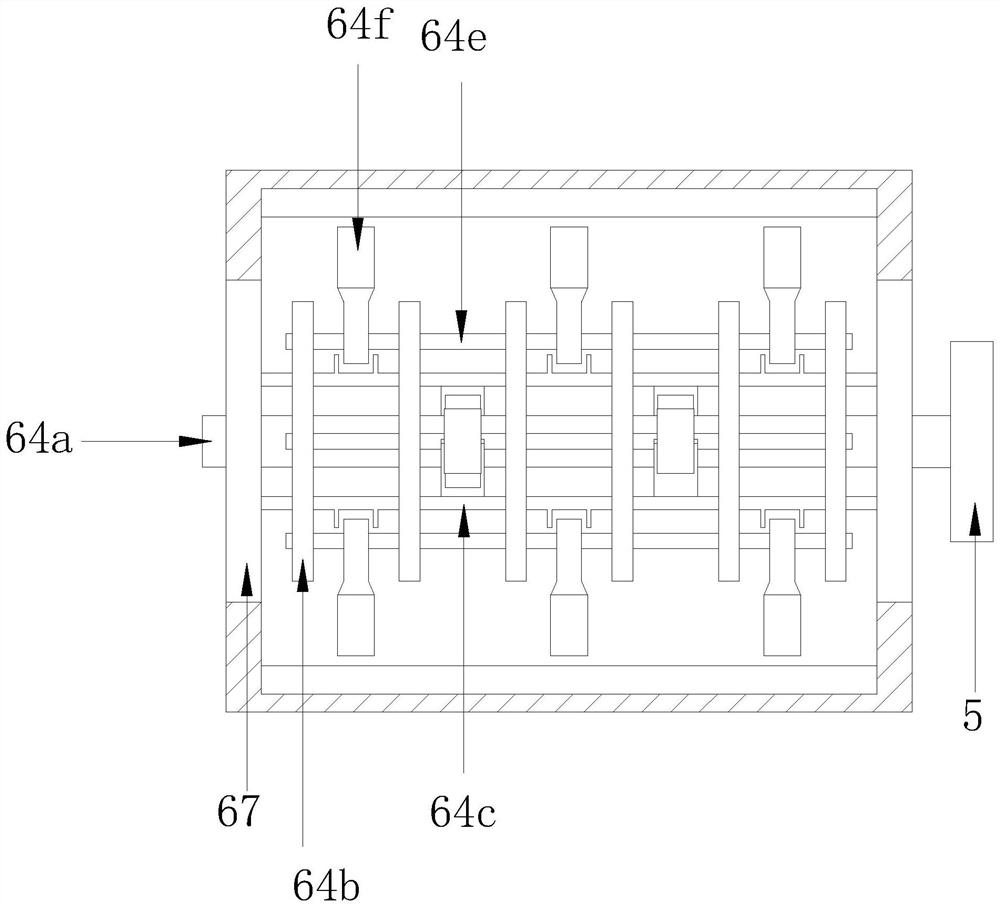

[0047] Such as figure 1 , figure 2 , Figure 9 , Figure 10 As shown, the present invention provides a technical solution of an environmentally friendly construction waste shredder: the structure includes a motor 1, a first transmission wheel 2, a supporting foot column 3, a base 4, a second transmission wheel 5, a shredder 6, and a transmission belt 7 , a base 4 is installed on the top of the supporting foot column 3, a motor 1 is provided on one side of the top of the base 4, the shaft of the motor 1 is connected with the first transmission wheel 2, and the first transmission wheel 2 passes through The transmission belt 7 is movably matched with the second transmission wheel 5, the second transmission wheel 5 is connected with the pulverizer 6, and the second transmission wheel 5 is connected with the transmission shaft 64a.

[0048] The pulverizer 6 includes a counterattack material frame 61, a pulverizer shell 62, a sieve plate 63, a pulverizer 64, a feed port 65, a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com