Electronic component quality detecting and screening device

A technology of quality inspection and electronic components, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of low efficiency, inconvenient screening, inconvenient component collection, etc., to achieve the effect of convenient collection and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

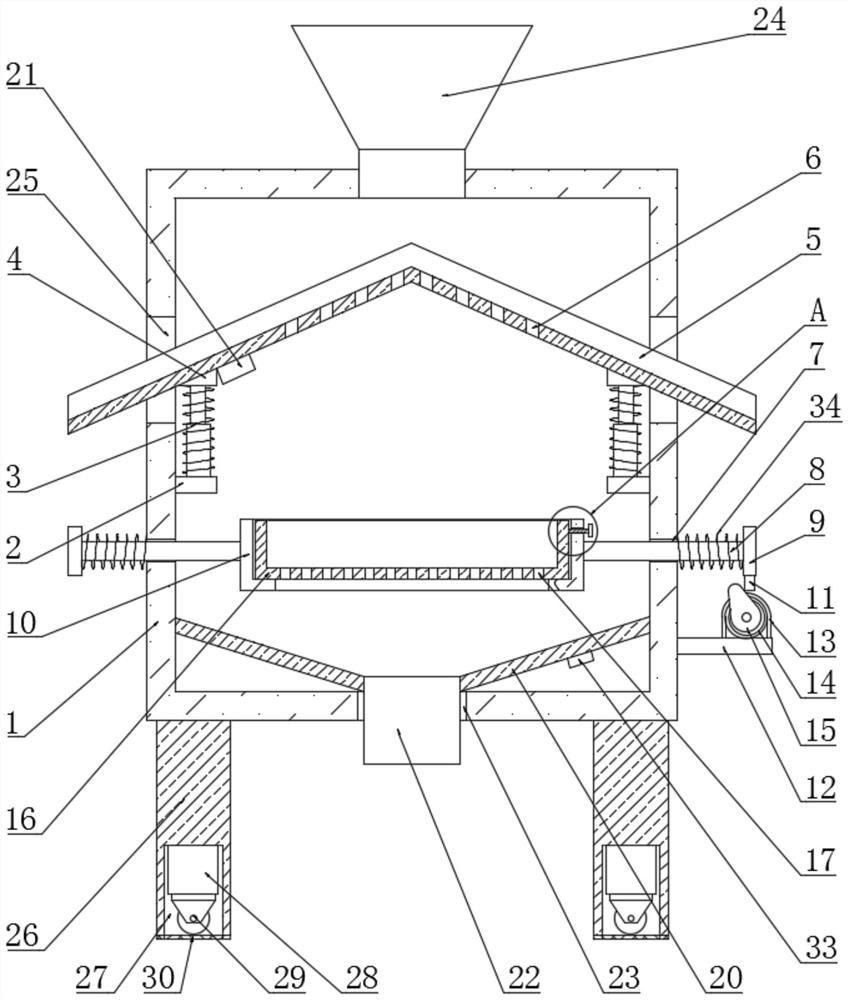

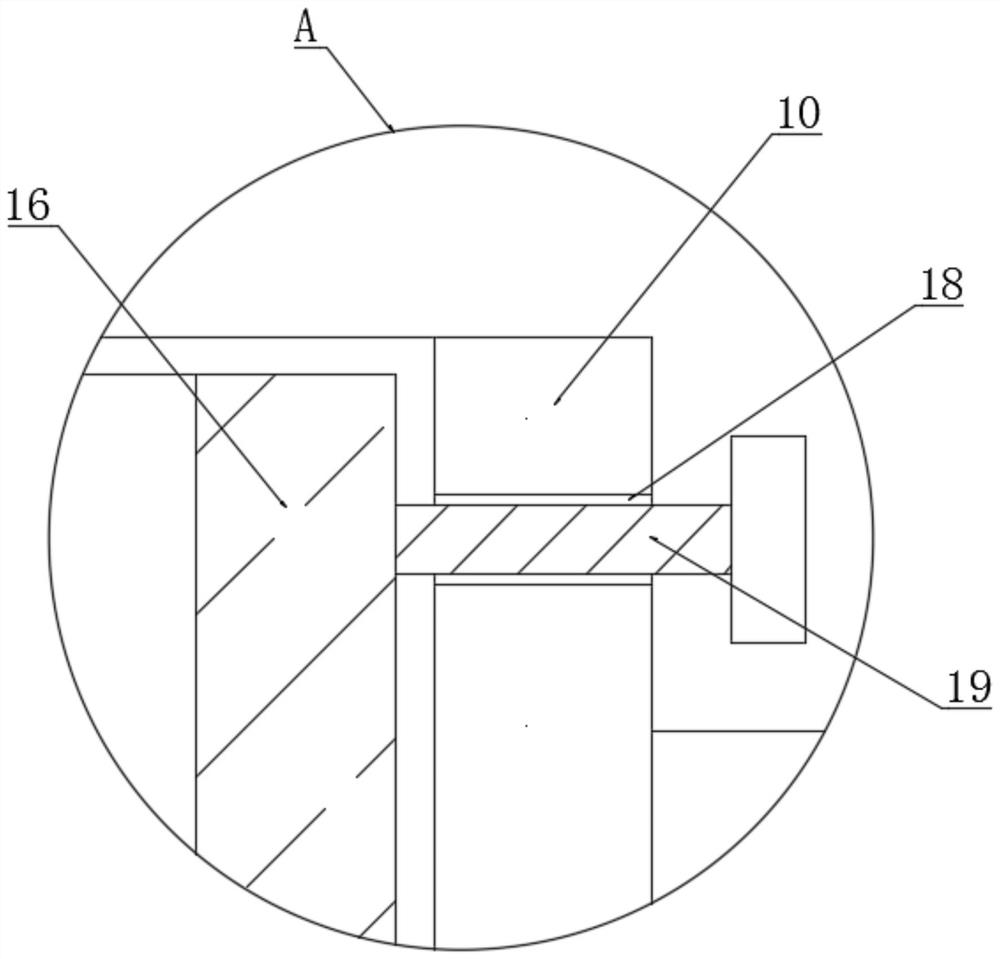

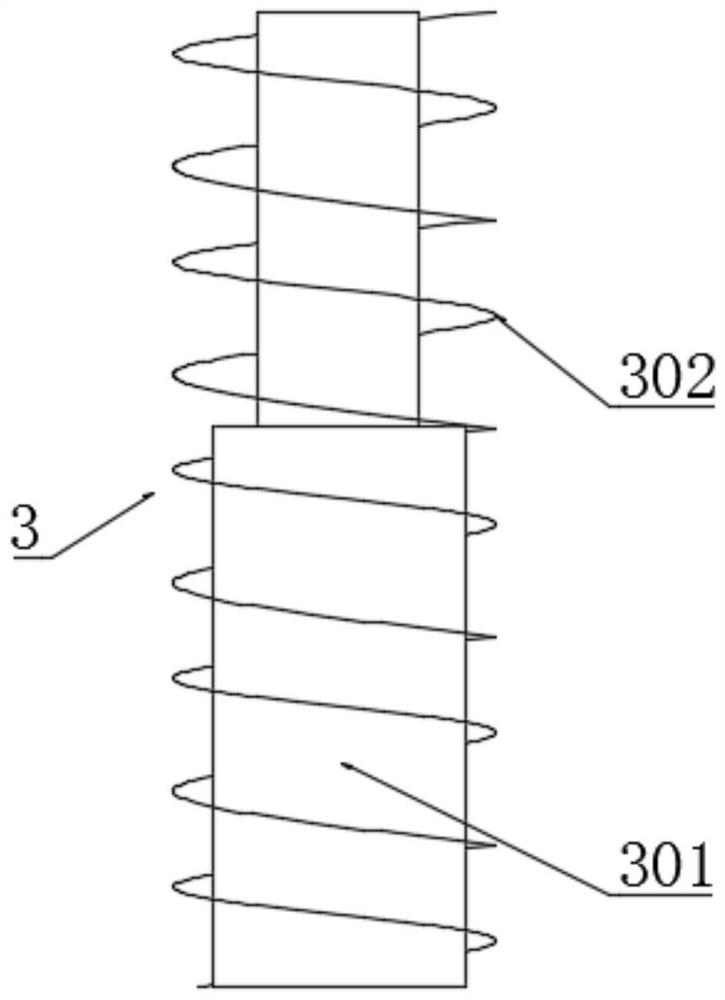

[0025] see Figure 1-4 , the present invention provides the following technical solutions: a quality detection and screening device for electronic components, including a housing 1, the opposite inner walls of the housing 1 are fixedly connected with first fixing plates 2, two of the first fixing plates The tops of the two telescopic assemblies 3 are fixedly connected with a telescopic assembly 3, the tops of the two telescopic assemblies 3 are fixedly connected with a fixed block 4, and the tops of the two fixed blocks 4 are fixedly connected with the same first screening frame 5. The bottom of the inner wall of the first screening frame 5 is provided with a first leakage hole 6, and the opposite inner wall of the housing 1 is provided with a movable hole 7, the number of the movable holes 7 is four, and the four movable holes 7 The interior of each slide bar 8 is movably connected, and one end of every two slide bars 8 is fixedly connected with the same second fixed plate 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com