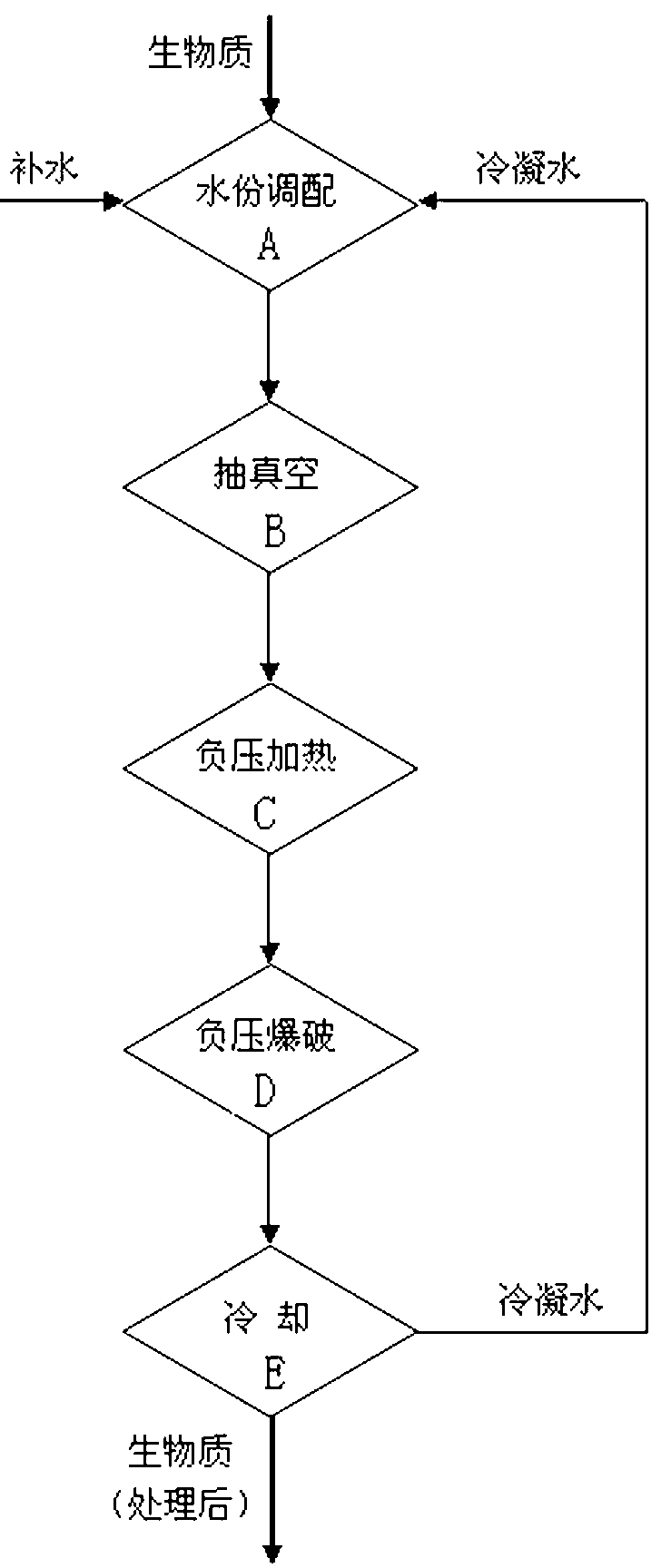

Biomass negative-pressure degradation pretreatment process

A biomass and pretreatment technology, applied to the removal of solid waste, etc., can solve the problems of high maintenance and operation costs, high labor intensity, and low degree of mechanization, so as to shorten the utilization cycle, save heating energy consumption, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0020] (A) The step is: put the biomass and water into the degradation kettle according to the mass ratio of 1.5:1, and carry out the biomass moisture allocation; (B) The step is: pump the degradation kettle into a vacuum negative pressure of -0.05MPa gauge pressure pressure environment; (C) step is: under negative pressure environment, heat the mixture of biomass and water to 110°C; (D) step is: instantaneously mix the mixture heated to 110°C and gauge pressure 0.09MPa with low temperature negative pressure The condensing device is connected to carry out instantaneous negative pressure blasting; (E) step is: cooling the mixture after blasting, cooling the degradation tank to 65°C, and returning the cooled liquid condensed water to the water allocation process of step (A) , reused in the degradation tank.

[0021] Among them, step (C) negative pressure heating: it is carried out in a negative pressure environment where the biomass and water are mixed at a mass ratio of 1:1.5, ...

Embodiment 3

[0023] (A) The step is: put the biomass and water into the degradation tank according to the mass ratio of 1:2, and carry out the moisture adjustment of the biomass; (B) The step is: pump the degradation tank into a vacuum negative pressure of -0.09MPa gauge pressure pressure environment; (C) step is: under negative pressure environment, heat the mixture of biomass and water to 150°C; (D) step is: instantaneously mix the mixture heated to 150°C and gauge pressure 0.4MPa with low temperature negative pressure The condensing device is connected to carry out instantaneous negative pressure blasting; (E) step is: cooling the mixture after blasting, cooling the degradation tank to 95°C, and returning the cooled liquid condensed water to the water allocation process of step (A) , reused in the degradation tank.

[0024] Among them: (C) step negative pressure heating: it is carried out in a negative pressure environment where the biomass and water are mixed in a mass ratio of 1:2 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com