TP support level detection line

A level detection and laser detection technology, applied in sorting and other directions, can solve problems such as low work efficiency, affecting work efficiency, and prone to errors, and achieve the effects of high work efficiency, improved production efficiency, and reliable detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in detail below, and examples of the embodiments are illustrated in the drawings, in which the same or similar reference numerals represent the same or similar elements or elements having the same or similar functions. By following with reference to the embodiments described are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

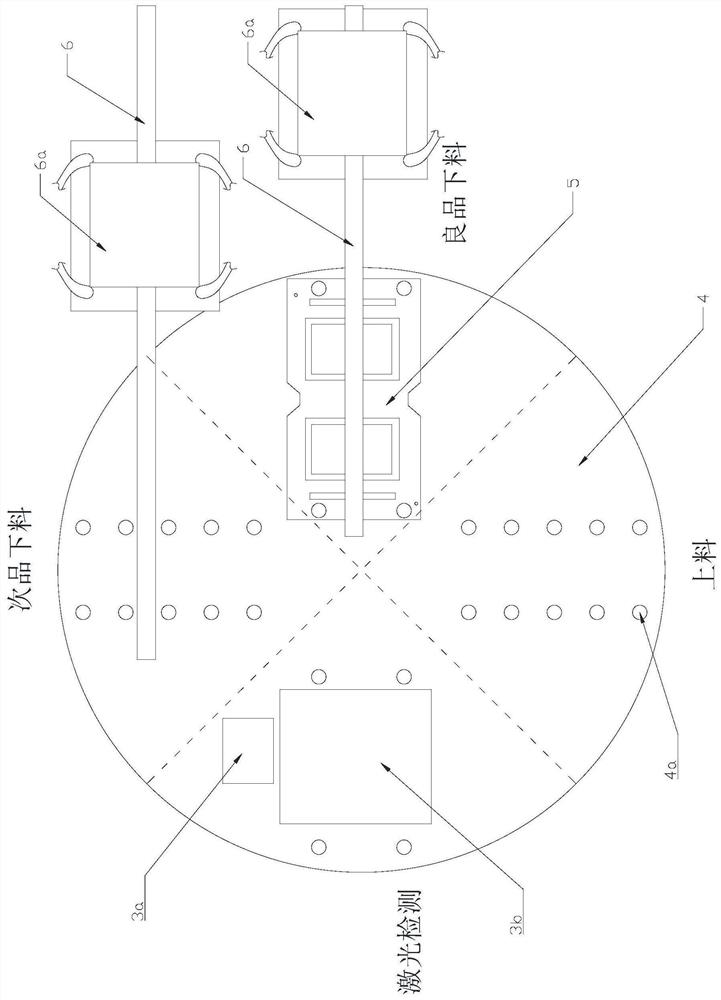

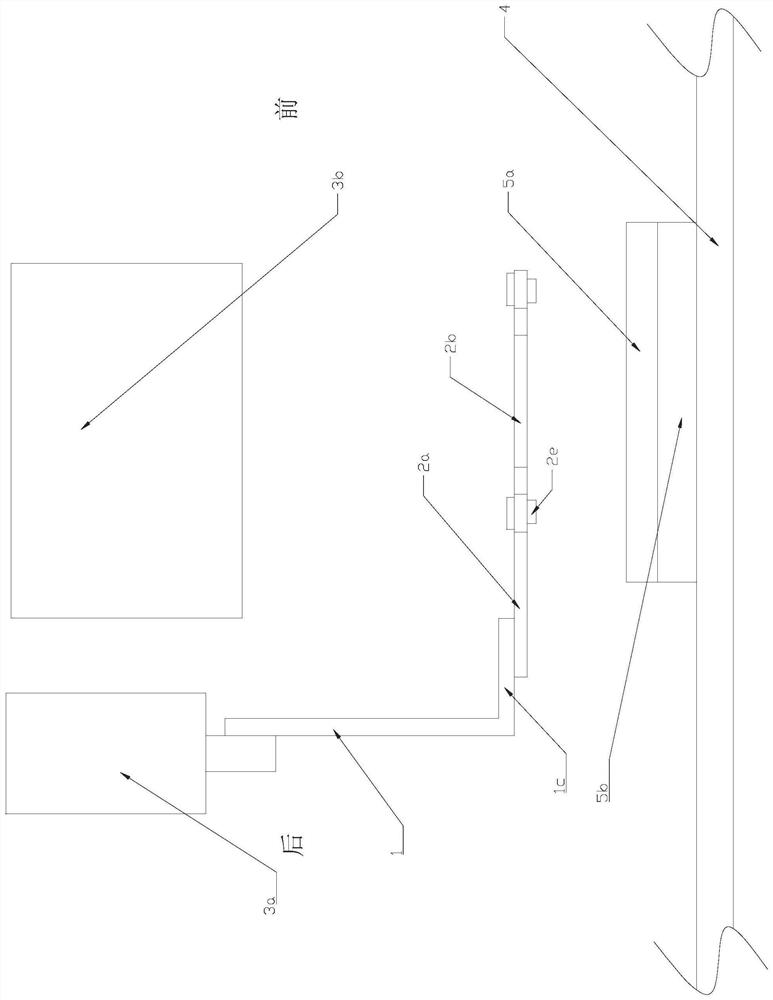

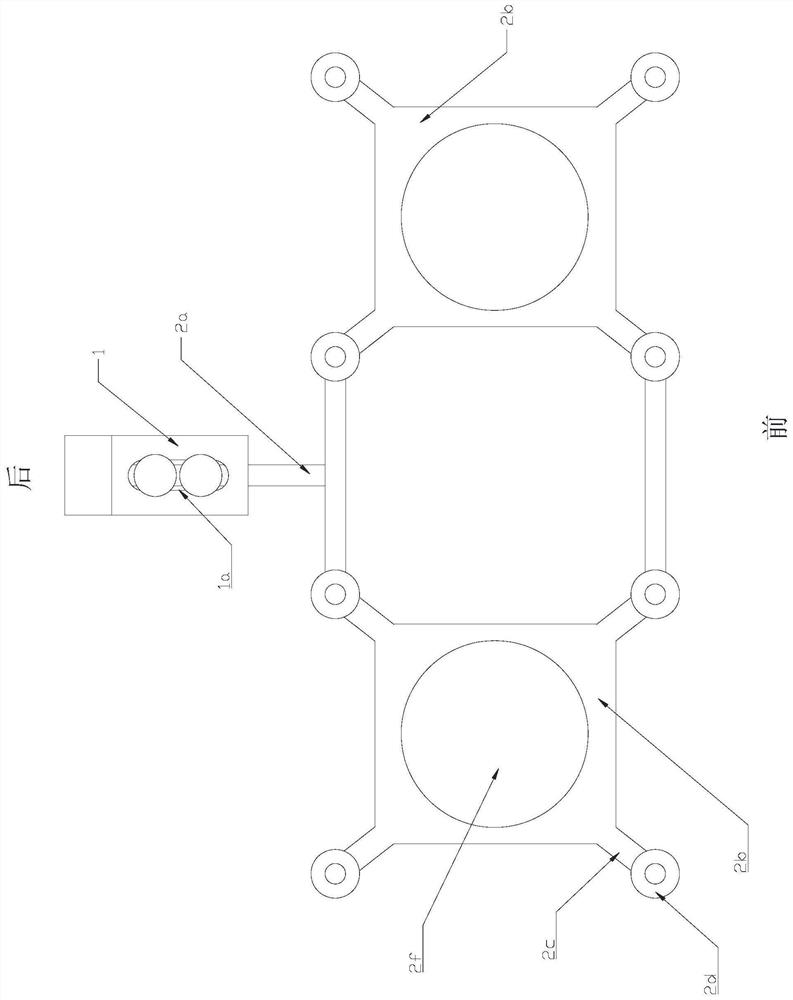

[0032] like Figure 1 - Figure 6 As shown in a horizontal test line TP stent, comprising carousel 4 around the dial 4 upward turn divided with a feeding station, a laser station detection and sorting station, with the bottom of the turntable 4 driven by its intermittent rotation of the rotation motor, the turntable 4 is rotated around the center of the turntable 4 is evenly distributed with a plurality of jig 5 and the jig 5 is rotated by the rotation of the motor sequentially loading station oriented, laser inspection station and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com