Board pressing device convenient to operate and used for shaving board processing

A technology of particleboard and pressing board, which is applied in the field of pressing board device for particleboard processing, which can solve the problem that raw materials cannot be evenly tiled, and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

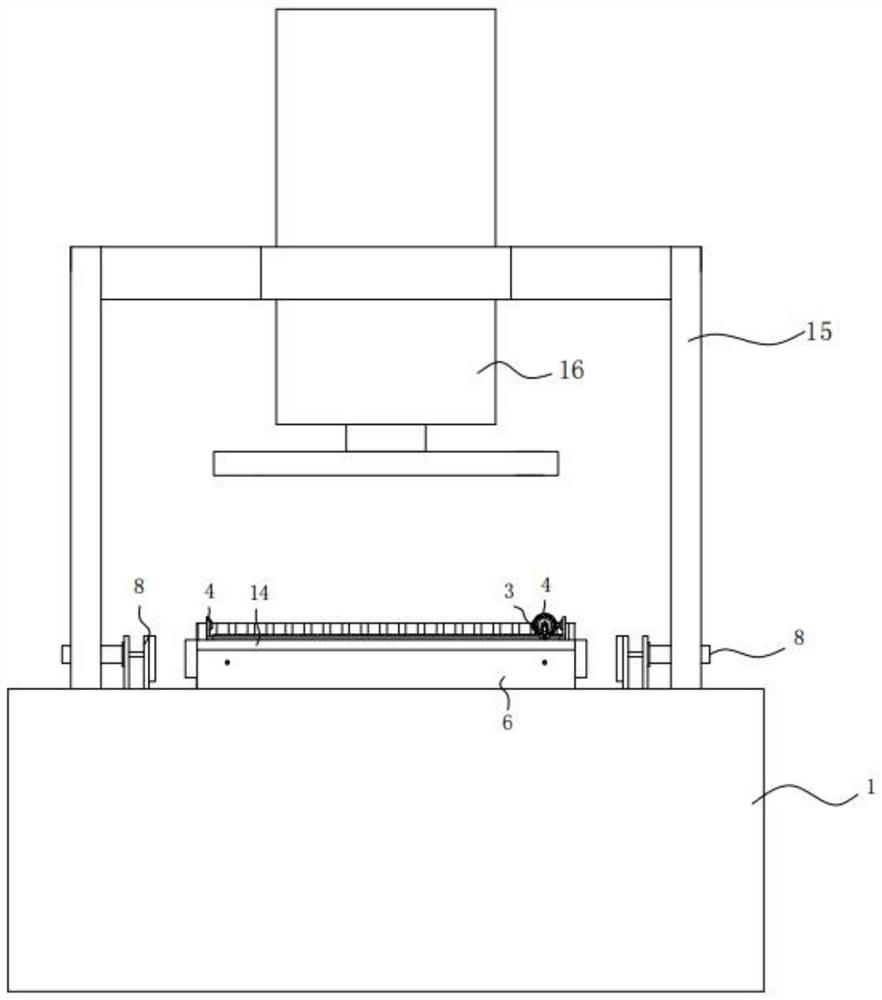

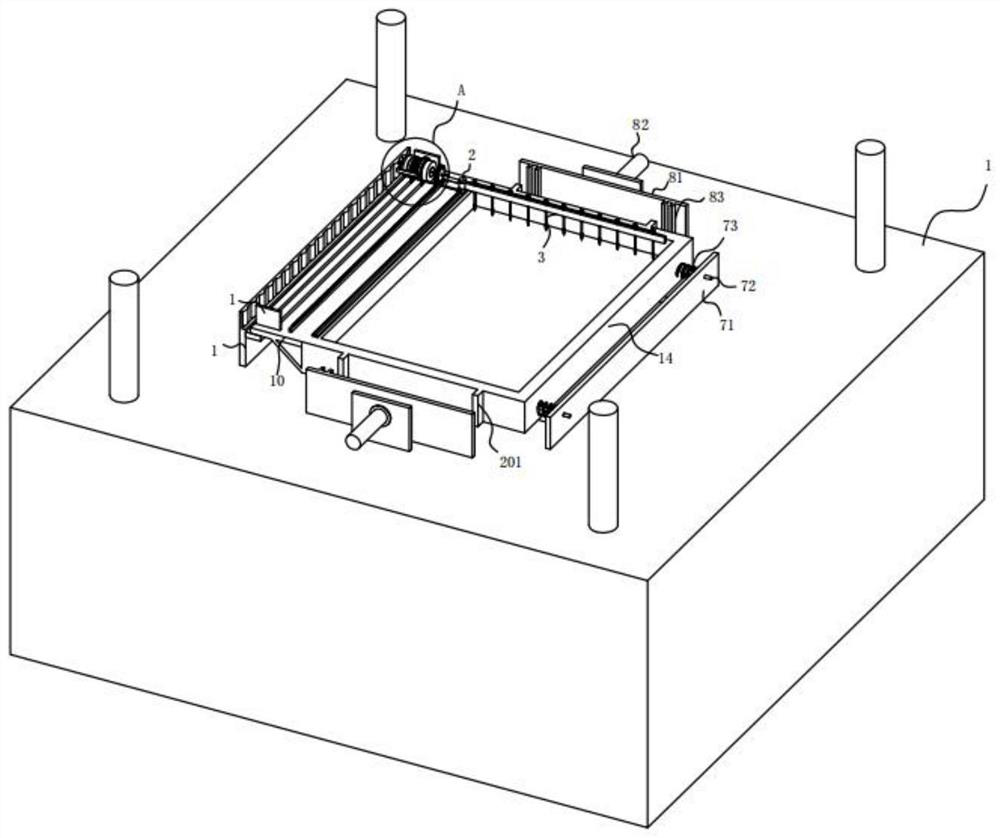

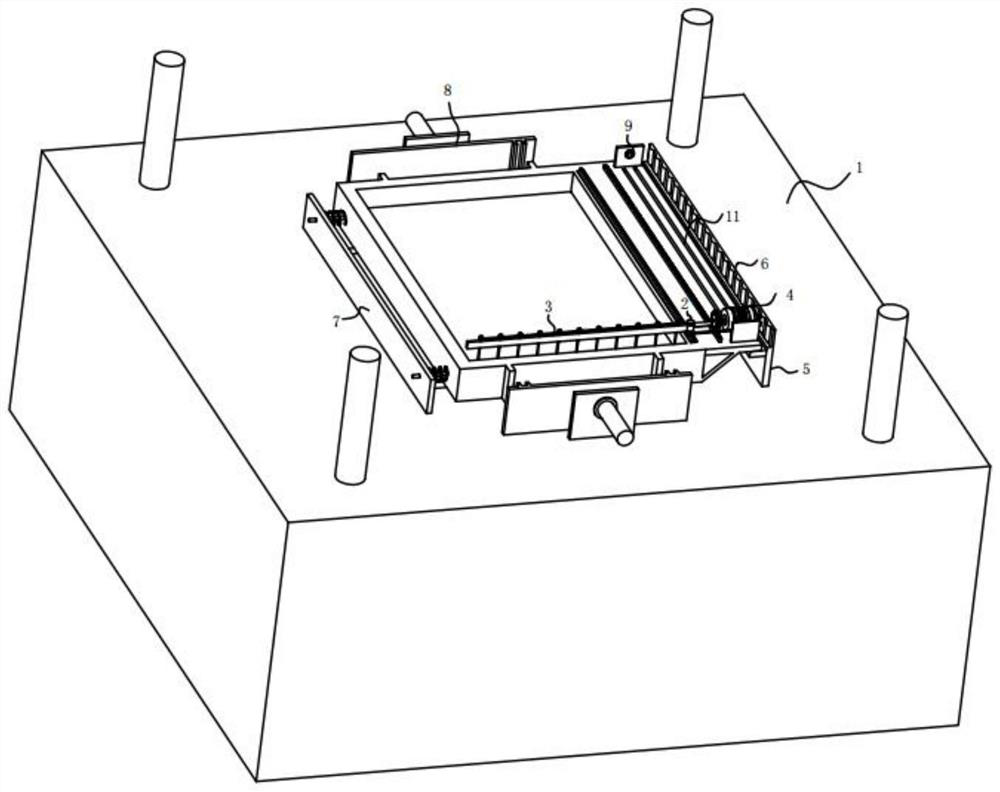

Image

Examples

no. 2 example

[0082] Please refer to Figure 9 Based on the easy-to-operate pressing device for processing particleboard provided in the first embodiment of the present application, the second embodiment of the application proposes another easy-to-operate pressing device for processing particleboard. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0083] Specifically, the difference between the easy-to-operate platen device for particleboard processing provided by the second embodiment of the present application is that, for the easy-to-operate platen device for particleboard processing, an installation cavity 18 is opened inside the workbench 1, and the The bottom of the inner wall of the installation chamber 18 is symmetrically provided with a third chute 19, and the inside of the installation chamber 18 is provided with a push-up assembly 17, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com