Center tube labeling machine and labeling method thereof

A center tube and labeling machine technology, applied in the directions of labeling machine, labeling, labeling, etc., can solve the problems of difficulty in ensuring the same position of labels, low labeling efficiency, and low labeling quality, etc., to improve labeling efficiency, Improve the degree of automation and improve the effect of labeling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

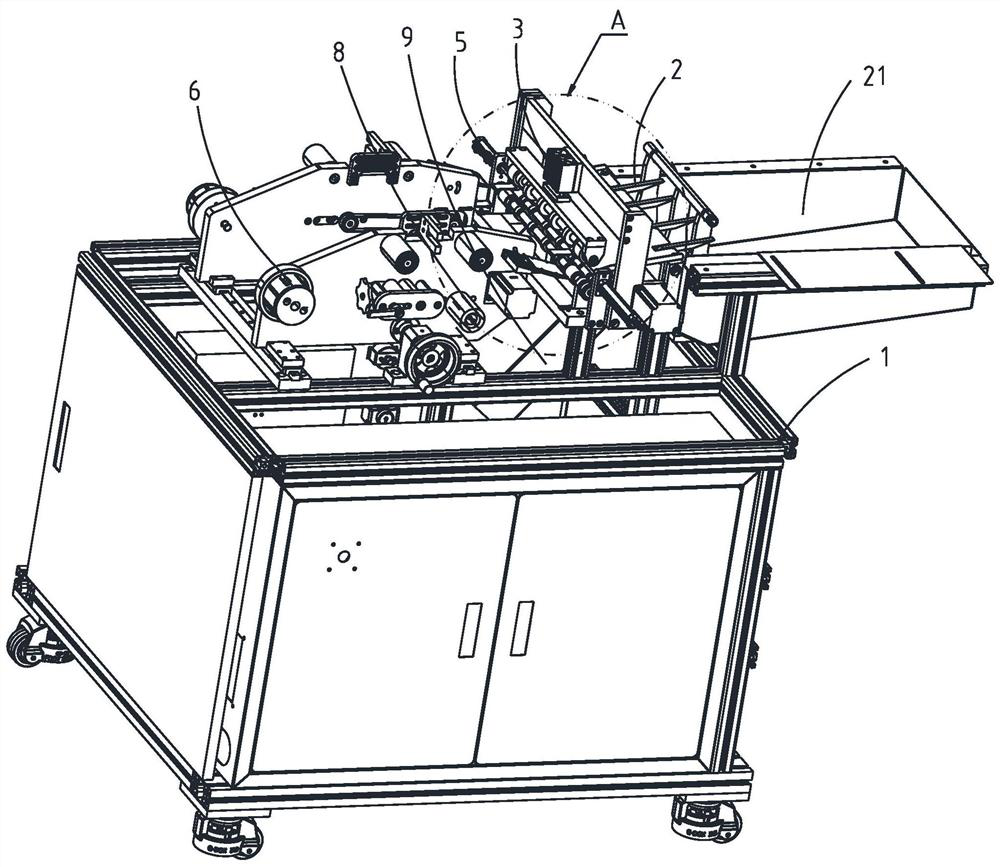

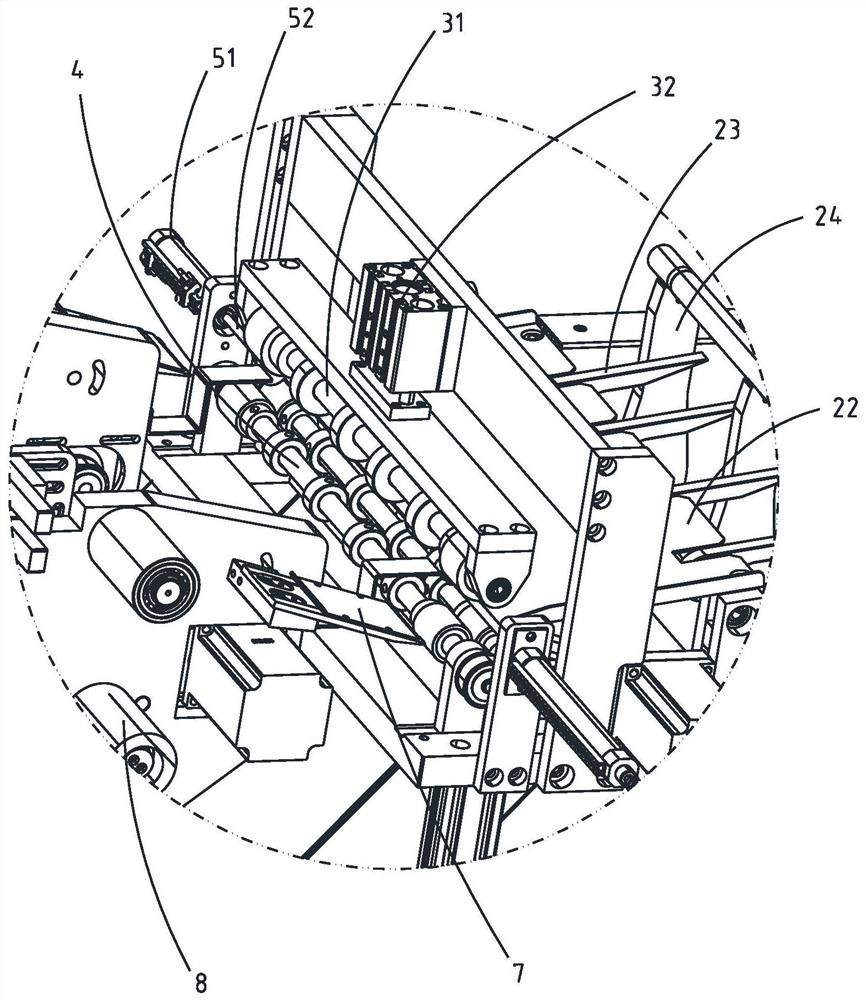

[0049] Such as figure 1 , 2 As shown, a central tube labeling machine includes a frame 1, a central tube feeding device 2, a label supply device, a central tube support device, a rotary drive device and a pressure roller device 3; wherein,

[0050] The central tube support device includes two support rollers 4 arranged side by side and respectively rotatably supported on the frame 1, and the two support rollers 4 jointly form a support position for supporting the central tube;

[0051] The central tube feeding device 2 is used to provide the central tube to the support position;

[0052] The label supply device is used to supply labels to the support position;

[0053] The pressure roller device 3 is used to compress the head of the label supplied by the label supply device on the central tube; and compress the central tube on the support position;

[0054] The rotary driving device is connected with a support roller 4, and is used to drive the center tube to rotate for lab...

Embodiment 2

[0087] Such as figure 1 , 2 As shown, a labeling method of a central tube labeling machine as described in Embodiment 1, the method steps include:

[0088] Step S1: the central tube feeding device 2 provides the central tube to the support position;

[0089] Step S2: the label supply device provides labels to the support position;

[0090] Step S3: the pressure roller device 3 presses the head of the label on the center tube, and at the same time presses the center tube on the support position, and the two support rollers 4 and the pressure roller device 3 jointly squeeze the center tube;

[0091] Step S4: The rotating driving device drives the supporting roller 4 to rotate, and the supporting roller 4 drives the central tube to rotate at a certain angle, and the label is completely attached to the central tube under the action of the pressing roller 31 of the pressing roller device 3 .

[0092] Step S5: The moving drive mechanism drives the slide plate to move away from on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com