Underground three-layer large-span column-free station structure

A large-span, station technology, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve the disadvantages of flexible arrangement of internal equipment and facilities, make full use of station space, double-decker and column-free stations cannot meet transfer and large passenger flow Requirements, prestressed reinforced concrete box girder structure construction process complex and other issues, to achieve the effect of saving investment in foundation pit engineering, improving the mechanical characteristics of the structure, and reducing the risk of foundation pit excavation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

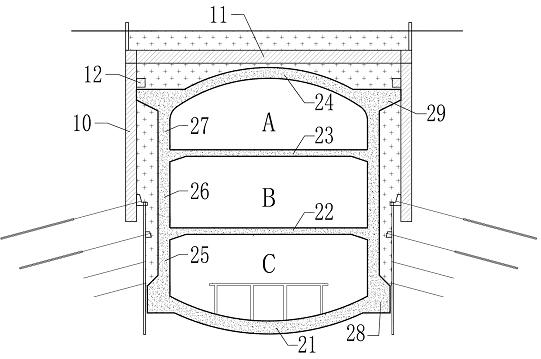

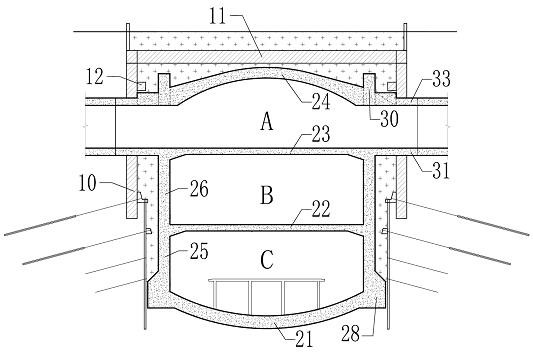

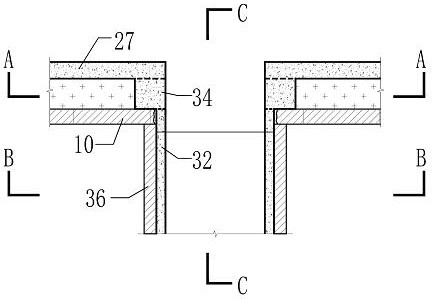

[0032] The underground long-span three-story pillarless station in the preferred embodiment of the present invention includes a hall floor A, an equipment floor B, and a platform floor C. see figure 1 , in the foundation pit enclosure structure 10, from bottom to top, it includes the platform layer C side wall 25 arranged on both sides, the bottom plate arch foot ear 28, and the bottom plate arch 21 arranged between the two platform layer C side walls 25 1. Equipment layer middle board 22; upwards are the equipment layer B side walls 26 located on both sides, the equipment layer middle board 22 and the station hall layer middle board 23 arranged between the two equipment layer B side walls 26; and then up These are the side walls 27 of the station hall layer A on both sides, the roof arch 24 arranged between the side walls 27 of the two station hall fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com