Pre-sealing type ice block production device for cleaning non-ferrous metal smelting pipeline

A non-ferrous metal and pipeline cleaning technology, applied in ice making, application, and ice manufacturing, etc., can solve the problems of quartz sand not being dispersed in time, reducing cleaning efficiency, affecting the installation of ice cubes, etc., to avoid low cleaning effect and reduce cleaning. Efficiency, avoid hole wall cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

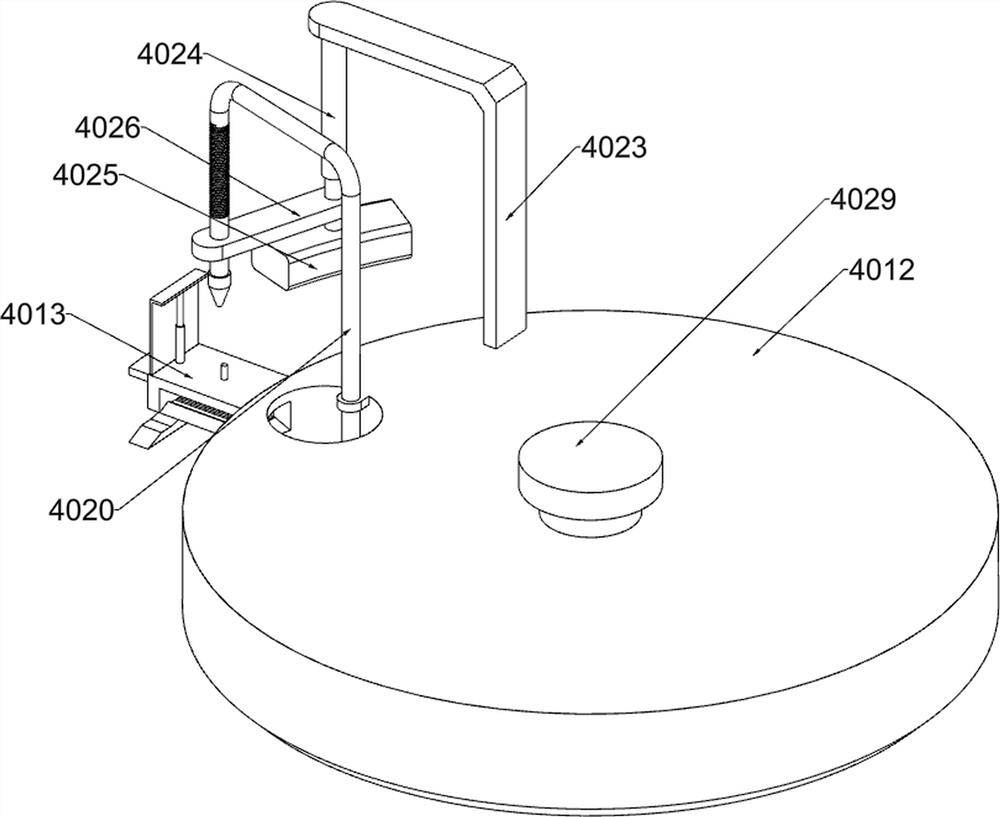

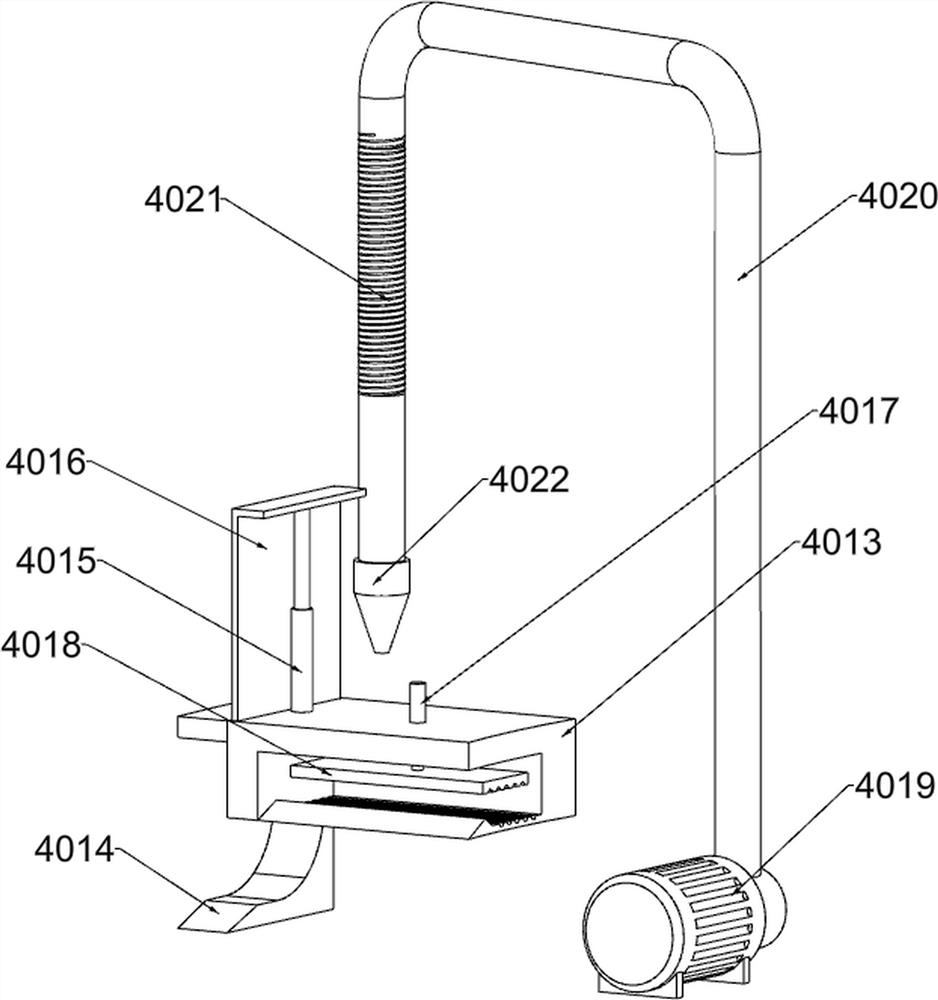

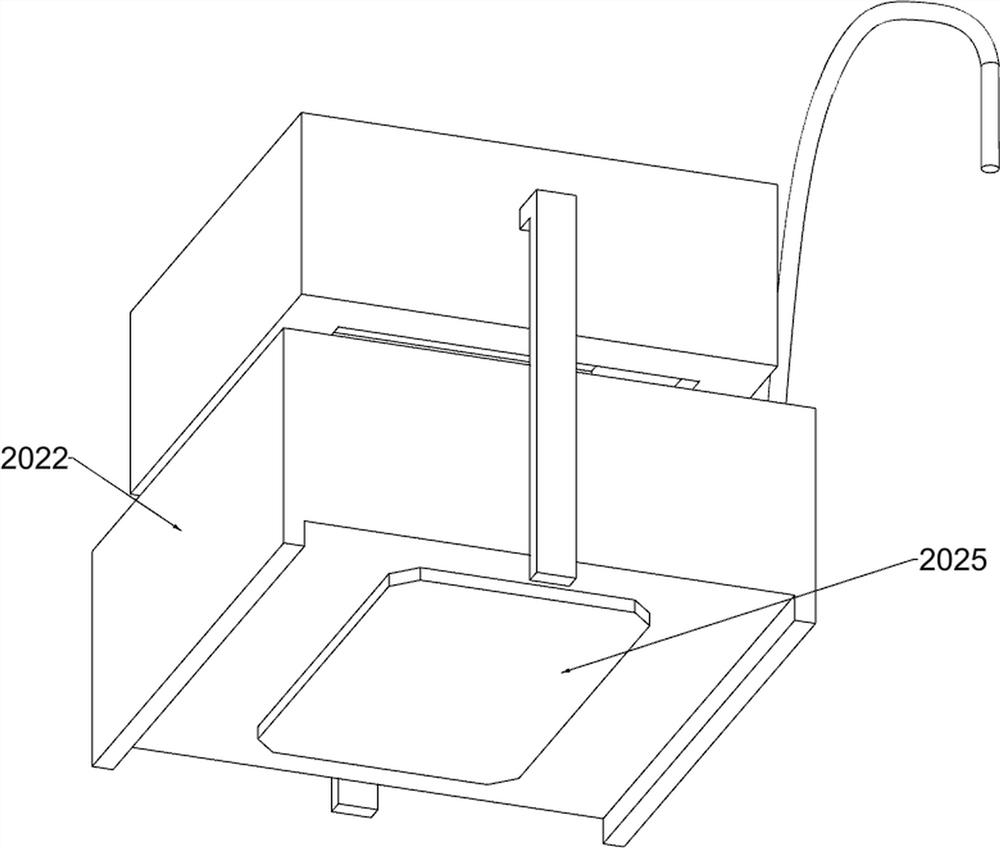

[0033] A pre-sealed ice block production device for cleaning non-ferrous metal smelting pipelines, such as Figure 1-3 As shown, it includes a bottom plate 1, a control panel 2, a support base 3, an anti-skid pad 4, a first support frame 5, a second support frame 6, a third support frame 7, a fourth support frame 8, a punching assembly, and a feeding components and blocking components; base plate 1 is fixed to the control panel 2; base plate 1 is fixed to four sets of support bases 3; base plate 1 is fixed to the first support frame 5; base plate 1 is fixed to the second support frame 6 connection; the bottom plate 1 is fixedly connected with the third support frame 7; the bottom plate 1 is fixedly connected with the fourth support frame 8; the bottom plate 1 is fixedly connected with the punching assembly capable of punching ice cubes; the four groups of support bases 3 are respectively It is fixedly connected with four sets of anti-skid pads 4; the first support frame 5 is f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap