Medical neurosurgery balloon injection molding device

An injection molding and neurosurgery technology, applied in the medical field, which can solve the problems of difficulty in removing the balloon and inconvenient demoulding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

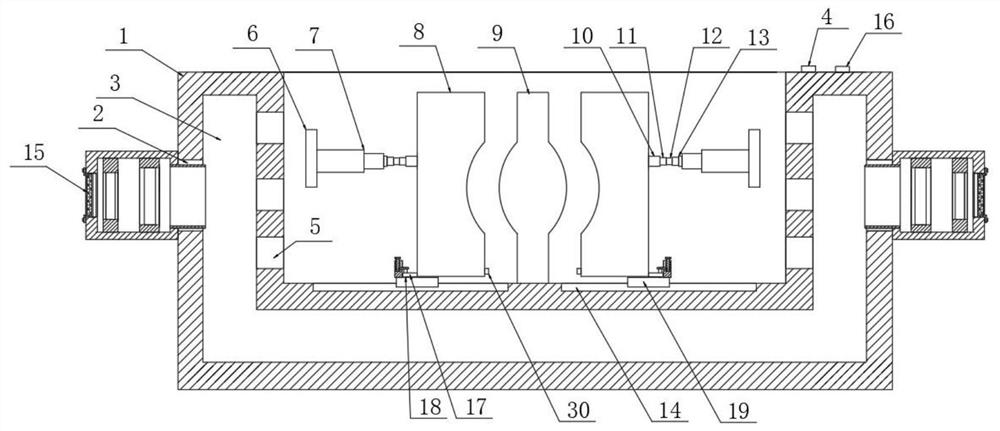

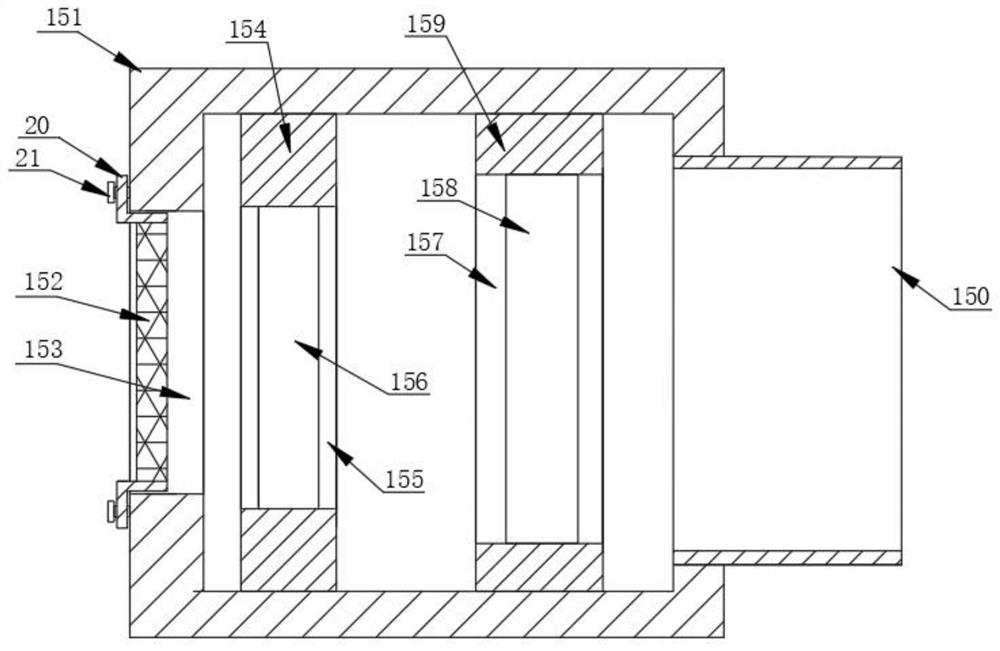

Embodiment 1

[0030] refer to Figure 1-2 And 4-6, a medical neurosurgical balloon injection molding device, including a mold body 1, positioning blocks 6 are fixedly arranged on both sides of the mold body 1, and an electric push rod 7 is fixedly installed on the inner side of the positioning block 6, and the electric push rod 7. A bearing 13 is fixedly installed at the telescopic end, and a small telescopic rod 12 is installed for rotation in the bearing 13. The telescopic end of the small telescopic rod 12 is fixedly connected with a screw rod 11. Connection, the bottom of the template 8 is provided with a slider 19, the template 8 is detachably mounted on the slider 19, the slider 19 is slidably set in the chute 14, the chute 14 is horizontally opened at the bottom of the mold body 1, and the bottom of the mold body 1 A positioning module 9 is fixedly arranged, and the positioning module 9 is arranged between the two templates 8. A gasket 30 is arranged on the inner side of the lower en...

Embodiment 2

[0037] refer to Figure 1-6 , a medical neurosurgery balloon injection molding device, comprising a mold body 1, positioning blocks 6 are fixedly arranged on both sides of the inside of the mold body 1, an electric push rod 7 is fixedly arranged on the inner side of the positioning block 6, and the telescopic end of the electric push rod 7 is fixed A bearing 13 is provided, and a small telescopic rod 12 is arranged to rotate inside the bearing 13. The telescoping end of the small telescopic rod 12 is fixedly connected with a screw 11, and the thread of the screw 11 is set in the sleeve 10. The sleeve 10 is fixedly connected with the template 8, and the template 8 The bottom is provided with a slider 19, the template 8 is detachably mounted on the slider 19, the slider 19 is slidably arranged in the chute 14, the chute 14 is set horizontally at the bottom of the mold body 1, and the inner bottom of the mold body 1 is fixedly provided with a positioning Module 9, the positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com