Sensor sealing process

A sensor and process technology, applied in the field of sensors, can solve problems such as product failure and failure to provide effective protection, and achieve the effect of reducing product failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

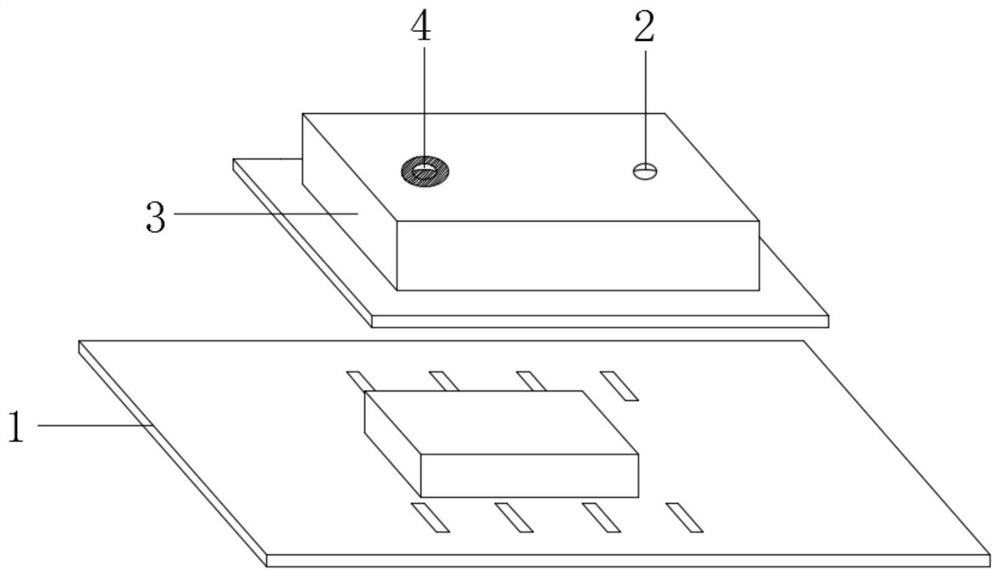

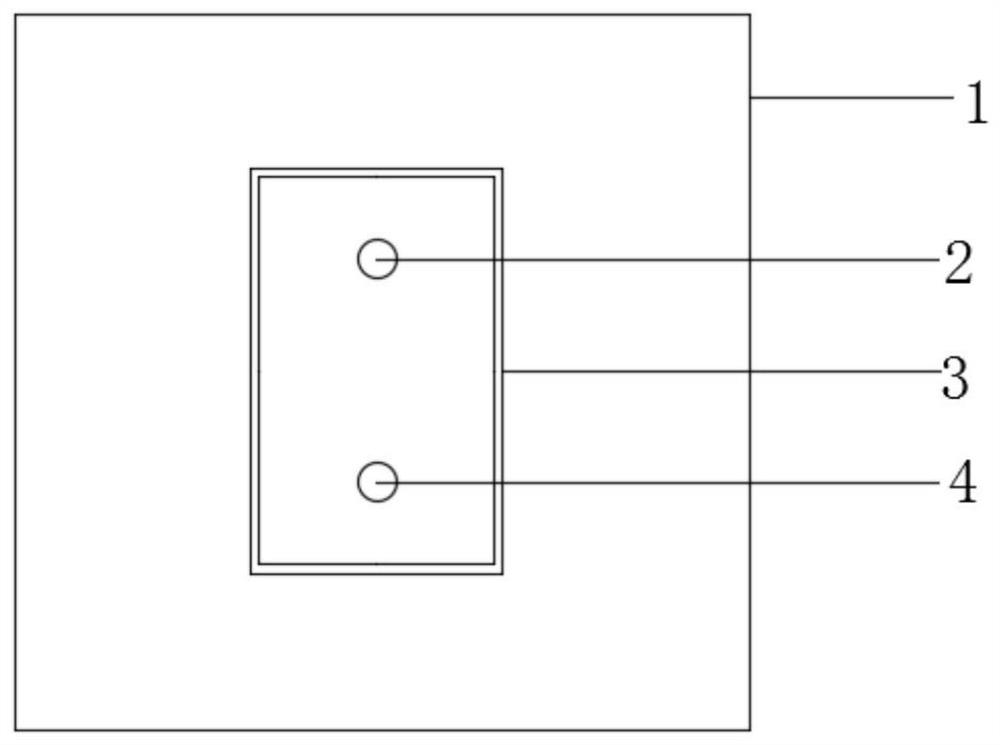

[0031] The invention provides a sensor sealing process, which has the advantages of dispensing and wrapping the pads and gold wires, only exposing the pressure sensing unit, and completely isolating water vapor. Please refer to figure 1 , including circuit board 1, glue injection hole 2, metal cover 3 and exhaust hole 4;

[0032] Further, the dispensing time of the dispensing machine is set to 2S, the air pressure is set to 20-25PSI, and the dispensing machine model is ZX-983A.

[0033] Further, in a high-temperature and high-pressure environment, align the glue injection needle with the glue injection hole 2 on the top of the sensor. The glue injection needle cannot touch the sensor. Step on the pedal of the glue dispenser lightly to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com