Batch cleaning and drying method for laboratory containers

A drying method and batch cleaning technology, applied in chemical instruments and methods, cleaning methods and utensils, drying gas arrangement, etc., can solve the problem of uncontrollable time of moving containers or moving drying devices, inconvenient operation, and inability to further improve the cleaning and drying efficiency of containers and other problems to achieve the effect of improving cleaning efficiency and cleaning effect and avoiding manual rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

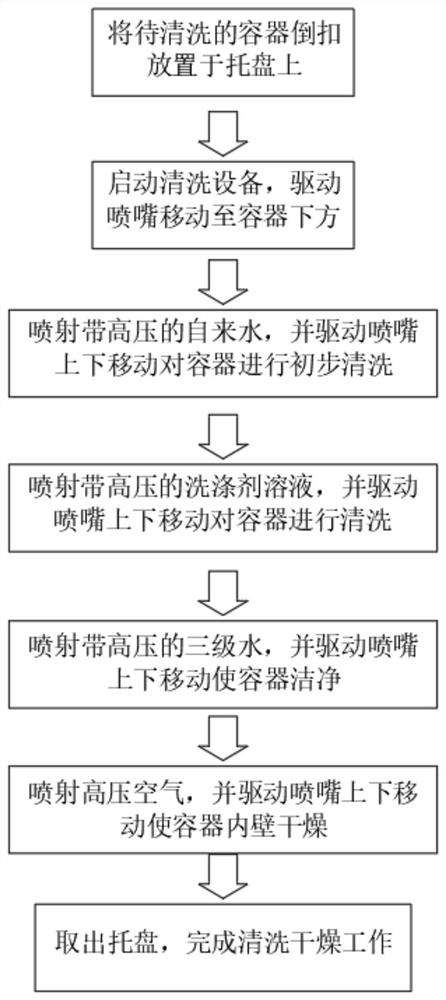

[0028] see Figure 1 to Figure 3 , the invention provides a batch cleaning and drying method for laboratory containers, comprising the steps of:

[0029] Step 1: Put the laboratory container to be cleaned upside down on the tray, and place the tray on the cleaning equipment. By buckling the container upside down on the tray, the waste liquid flows out from the bottle mouth of the container under the action of gravity during cleaning, so as to improve the cleaning effect. At the same time, placing the bottle mouth of the container downward can effectively prevent liquid splashing during the cleaning process and improve the environmental friendliness of the cleaning equipment.

[0030] Step 2: Put the cover of the cleaning equipment on the cleaning equipment and start the cleaning equipment. The cover body is covered on the cleaning equipmen...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap