Carrying method for cleaning wafer after CMP

A post-cleaning and wafer technology, applied in the direction of conveyor objects, electrical components, transportation and packaging, etc., can solve the problems of long transportation time, cleaning capacity can not meet high demand, low cleaning method transportation efficiency, etc., to reduce transportation time, improve cleaning efficiency, and increase productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

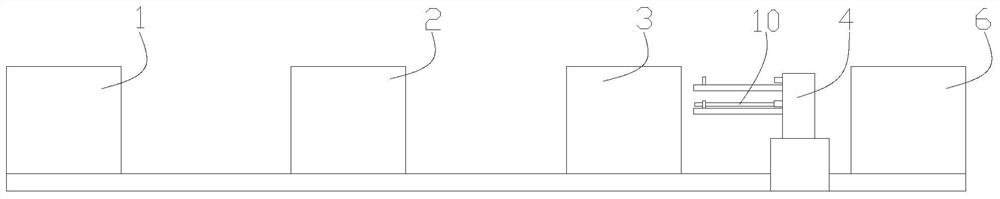

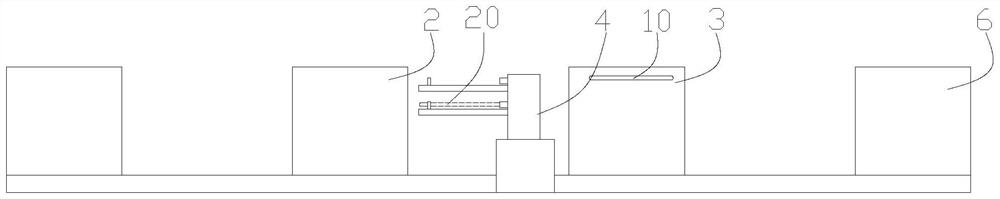

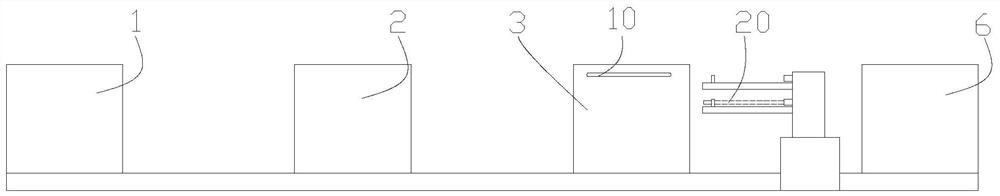

[0028] Please refer to the attached figure 1 , in the transfer method for post-CMP cleaning of wafers described in the embodiment of the present invention, it includes a transfer unit 1 , a first cleaning unit 2 , a second cleaning unit 3 , a double manipulator 4 and a loading table 6 .

[0029] Specifically, the handover unit 1 mainly plays the role of handover with the wafers after CMP in the previous process, accepts the wafers processed by CMP, and pre-cleanes these wafers; wherein, the operation process of pre-cleaning In order to immerse the wafers in ozone water and clean them by ultrasonic waves, the wafers here are immersed in ozone water in groups of two, while ensuring that the wafers are in a wet state.

[0030] Wherein, the cleaning process of the first cleaning unit is as follows: when the brush rotates, the wafer is brushed with pure water and alkaline chemical solution in sequence; the cleaning process of the second cleaning unit is as follows: the nozzle seque...

Embodiment 2

[0043] The invention discloses a method for transporting various wafers after CMP cleaning, which comprises the following steps:

[0044] Step S01 , the handover unit receives the wafer after CMP and performs moisturizing.

[0045] Step S02 , the double manipulators transport the first wafer 10 in the transfer unit to the first cleaning unit for cleaning with a brush combined with pure water and alkaline liquid for 130 seconds.

[0046] Step S03 , the double manipulators transport the first wafer 10 after the first cleaning to the second cleaning unit, spray nozzles with ozone and acidic liquid, and then dry it. This process takes 190 seconds.

[0047] Step S04, the double manipulator returns to the handover unit, and transfers the second wafer 20 in the handover unit to the first cleaning unit for the first cleaning for 130 seconds. At this time, the first wafer 10 is cleaned in the second cleaning unit .

[0048]Step S05, when the second wafer 20 continues to be moisturize...

Embodiment 3

[0052] Please refer to the attached Figure 4 The difference between this embodiment and Embodiment 1 is that a temporary storage unit 5 is installed between the loading table and the second cleaning unit for storing wafers that cannot be placed after cleaning by the second cleaning unit 4 .

[0053] The invention discloses a method for transporting various wafers after CMP cleaning, which comprises the following steps:

[0054] Step S01 , the handover unit receives the wafer after CMP and performs moisturizing.

[0055] Step S02 , the dual manipulators transport the first wafer in the delivery unit to the first cleaning unit for cleaning with a brush combined with pure water and alkaline chemical solution for 120 seconds.

[0056] Step S03 , the double manipulators transport the first wafer after the first cleaning to the second cleaning unit for spray cleaning with nozzles combined with ozone and acidic liquid, and then dry it. This process takes 180 seconds.

[0057] Step...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap