Cleaning device for valves

A technology for cleaning devices and valves, which is applied to the cleaning method using liquid, the cleaning method using gas flow, and the arrangement of dry gas, etc., can solve the problems of difficulty in meeting the needs of large-scale valve production, unclean cleaning, and high labor intensity. Conducive to cleaning, better effect, lower labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

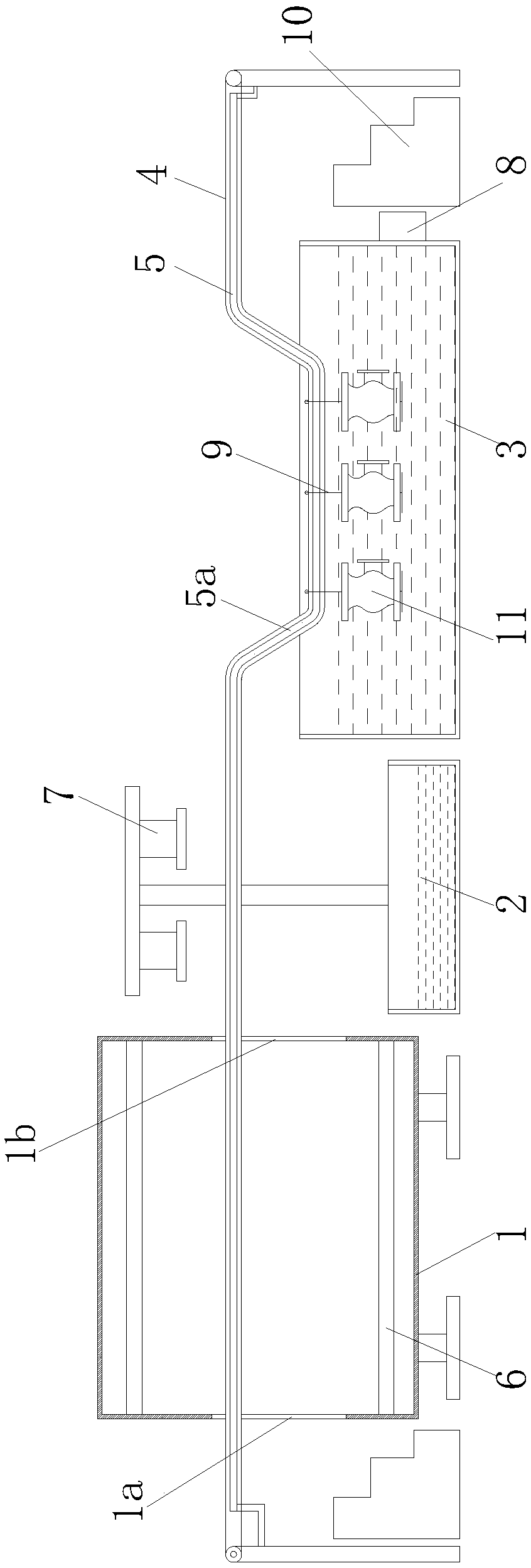

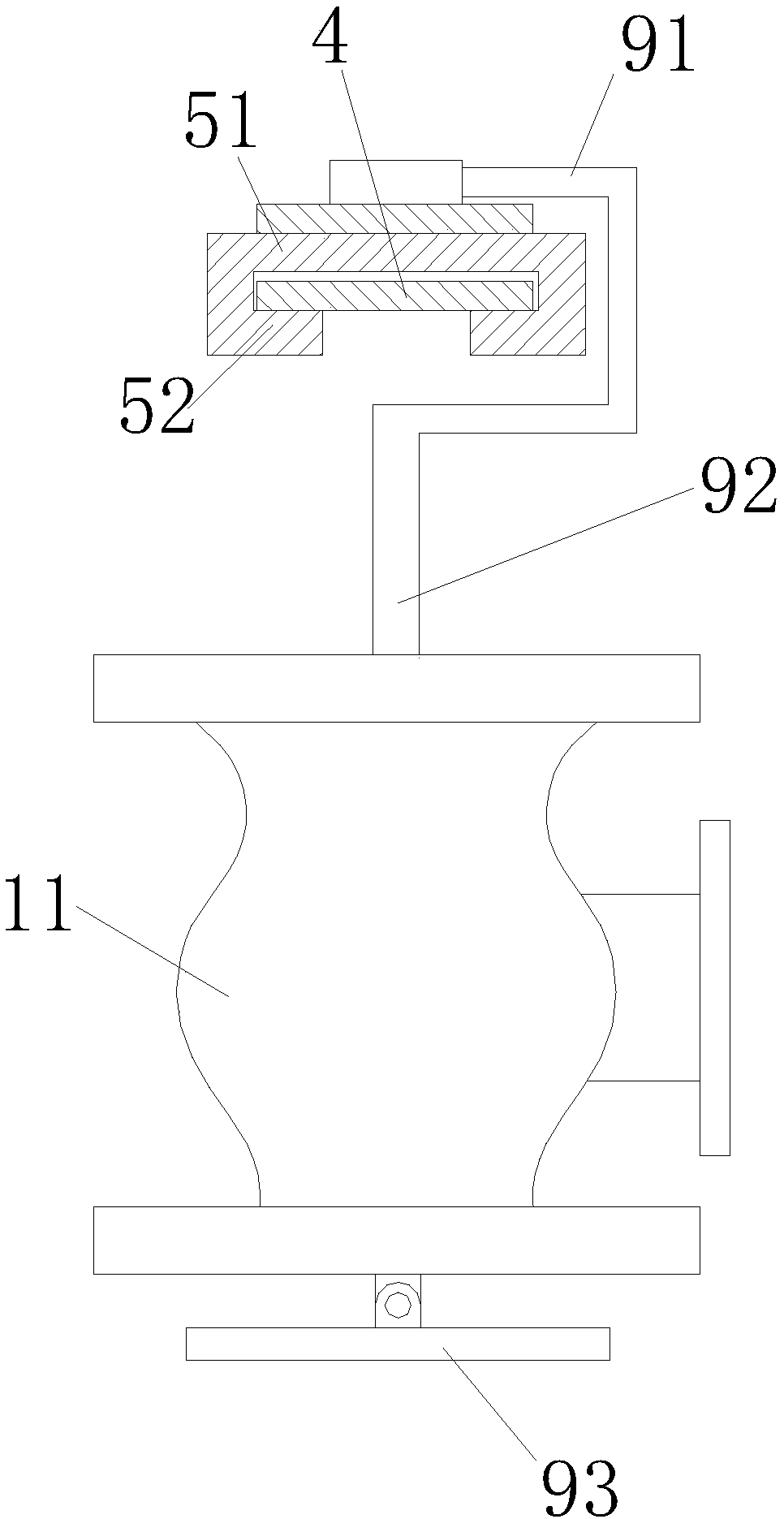

[0018] Such as Figure 1 to Figure 2 As shown, a valve cleaning device includes a drying box 1, a water storage tank 2, and a cleaning box 3 arranged sequentially from left to right; Line 4, a support guide plate 5 is provided between the upper and lower chains of the chain conveying line 4, and an inverted trapezoidal guide portion 5a is provided at the corresponding position of the support guide plate 5 and the cleaning box 3. When in use, the inverted trapezoidal guide part 5a facilitates sinking the valve 11 on the chain conveying line 4 into the cleaning box 3, which is efficient and fast.

[0019] The upper and lower walls of the drying box 1 are fixed with heating rods 6, and the upper end of the water storage tank 2 is provided with several air blowers 7 arranged in rows with t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap