Swing arm pressing assembly of leading shoe in engineering machinery

A technology for engineering machinery and pressing components, which is applied in the direction of metal processing machinery parts, clamping devices, manufacturing tools, etc., and can solve problems such as unsatisfactory clamping fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

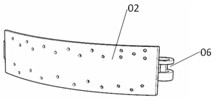

[0037] like Figure 1~4 As shown, a swing arm pressing assembly of a leading shoe in a construction machine includes a bottom plate 1, an assembly rod 2 is arranged on the bottom plate 1, and a left adjustment arm 3 that can be rotated and adjusted is arranged on the outer wall of the assembly rod 2. The right adjusting arm 4, the left adjusting arm 3 and the right adjusting arm 4 are provided with a vertical rod 5, and the vertical rod 5 is covered with a top sleeve 6 supporting the inner side of the arc beam 01, and the bottom plate 1 is also provided with A swing arm 8 is provided, and a pressing sleeve 9 is arranged on the swing arm 8, and the pressing sleeve 9 presses the arc-shaped mounting plate 02 of the collar shoe as the swing arm 8 moves.

[0038] There are two swing arms 8, and the swing directions of the two swing arms 8 are opposite in the compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com