Adjustable bending device for coil packaging material

A packaging material and bending device technology, applied in the packaging field, can solve the problems of low practicability, high degree of manual intervention, and inconvenient operation, and achieve the effect of convenient observation and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

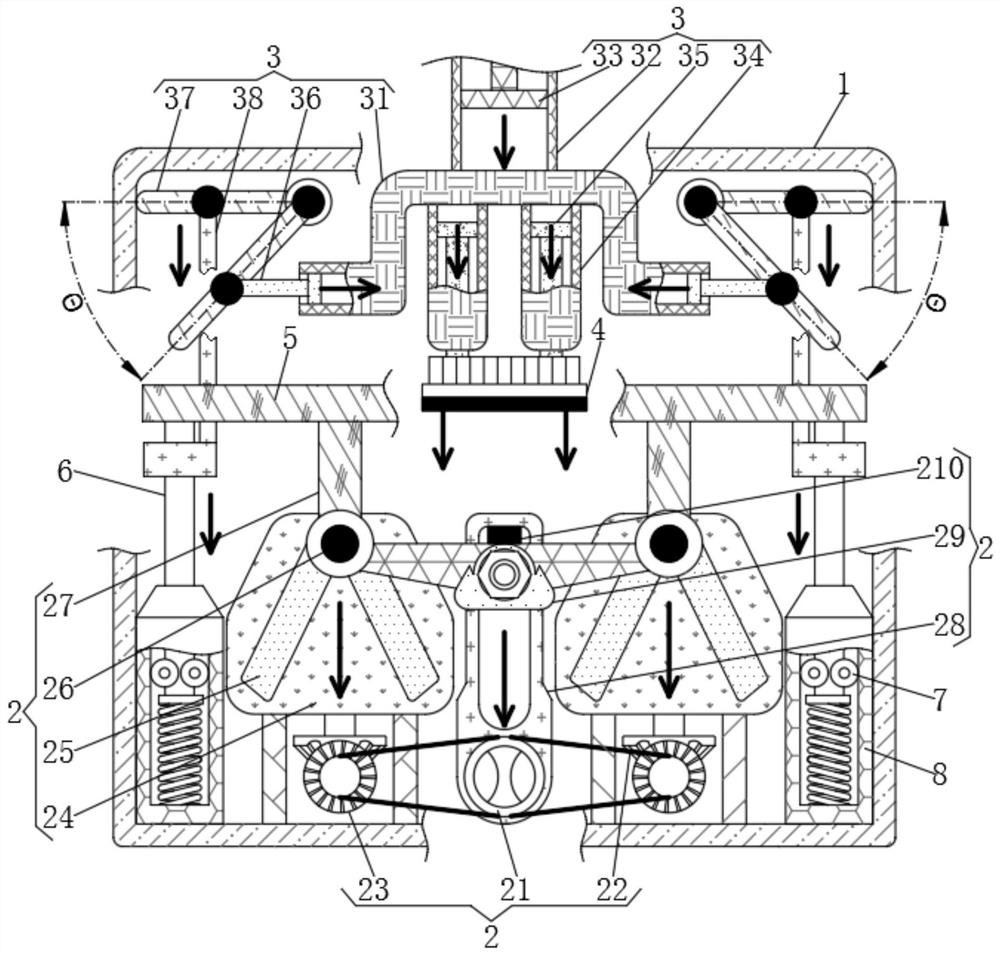

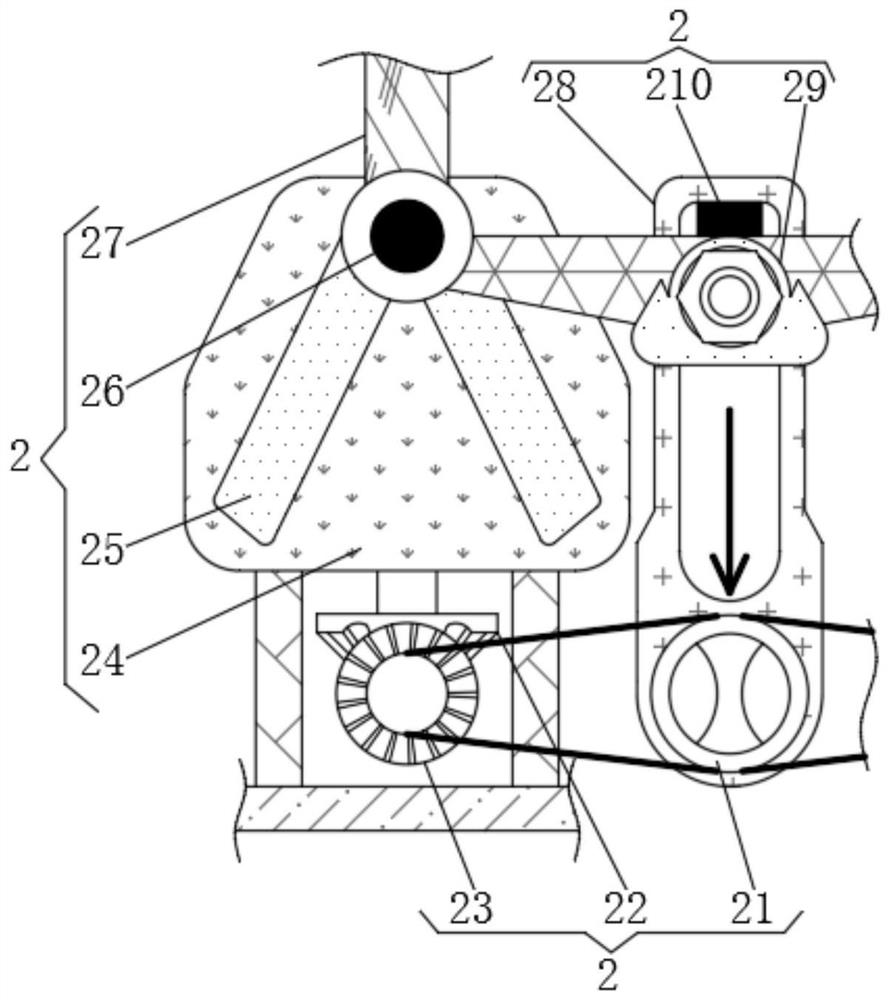

[0024] see Figure 1-3 , an adjustable bending device for coil packaging materials, including a casing 1, a position control mechanism 2, a bending mechanism 3, a pressing tool 4, a blocking plate 5, an inner rod 6, a roller 7 and an outer tube 8.

[0025] The position control mechanism 2 includes a rotary knob 21. Both sides of the rotary knob 21 are rotatably connected with a bevel wheel 1 22, a surface of the bevel wheel 1 22 is rotatably connected with a bevel wheel 2 23, and a top of the bevel wheel 22 is welded with a rotating column 24. The surface of the rotating column 24 is clamped with a channel 25, a clamping column 26 is clamped in the channel 25, a support rod 27 is welded on the surface of the clamping column 26, and a groove plate 28 is fixedly connected to the outer side of the rotating column 24. A sliding block 29 is slidably connected on the surface, a contact block 210 is provided on the top of the sliding block 29, a pull rope is sleeved on the outer side...

Embodiment 2

[0028] see Figure 1-3 , an adjustable bending device for coil packaging materials, including a casing 1, a position control mechanism 2, a bending mechanism 3, a pressing tool 4, a blocking plate 5, an inner rod 6, a roller 7 and an outer tube 8.

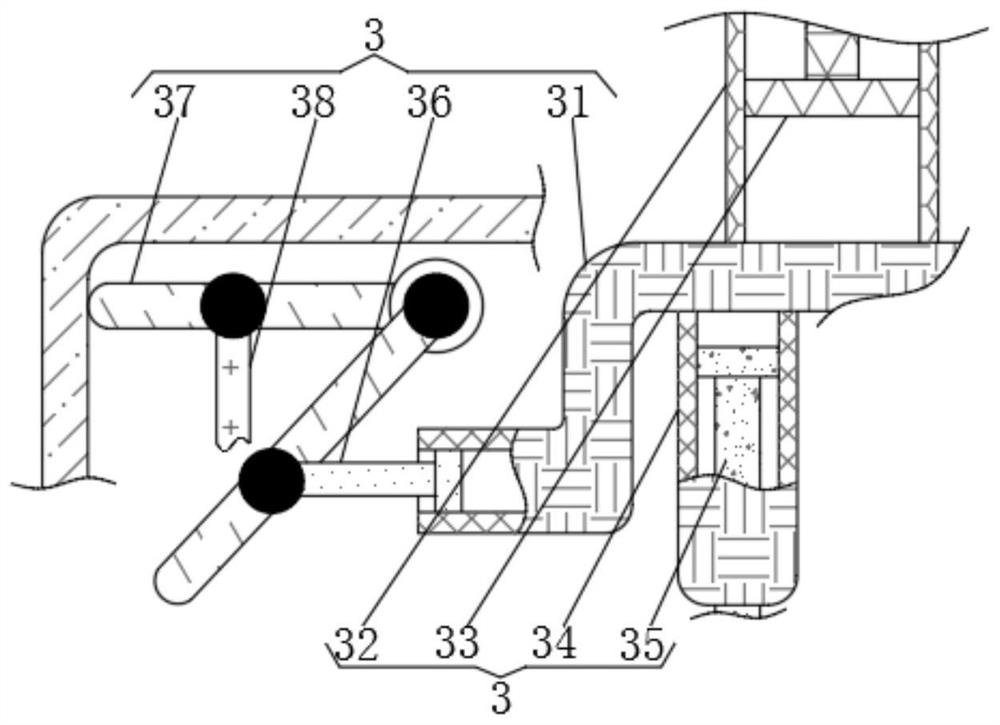

[0029] The crimping mechanism 3 includes a communication pipe 31, a main pipe 32 is welded on the top of the communication pipe 31, a piston one 33 is slidably connected to the inside of the main pipe 32, and a secondary pipe 34 is welded to the bottom of the communication pipe 31, and a piston is slidably connected to the inside of the secondary pipe 34. Two 35, both ends of the communication pipe 31 are slidably connected with a piston three 36, the outer side of the piston three 36 is rotatably connected with a rotating rod group 37, and the outer side of the rotating rod group 37 is movably connected with a follower rod 38, and the outer side of the piston one 33 is provided with There is a cylinder, and the driving of the cyli...

Embodiment 3

[0032] see Figure 1-3 , an adjustable bending device for coil packaging materials, including a casing 1, a position control mechanism 2, a bending mechanism 3, a pressing tool 4, a blocking plate 5, an inner rod 6, a roller 7 and an outer tube 8.

[0033] The position control mechanism 2 includes a rotary knob 21. Both sides of the rotary knob 21 are rotatably connected with a bevel wheel 1 22, a surface of the bevel wheel 1 22 is rotatably connected with a bevel wheel 2 23, and a top of the bevel wheel 22 is welded with a rotating column 24. The surface of the rotating column 24 is clamped with a channel 25, a clamping column 26 is clamped in the channel 25, a support rod 27 is welded on the surface of the clamping column 26, and a groove plate 28 is fixedly connected to the outer side of the rotating column 24. A sliding block 29 is slidably connected on the surface, a contact block 210 is provided on the top of the sliding block 29, a pull rope is sleeved on the outer side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com