Waterproof coiled material lap joint structure

A technology for waterproofing membranes and connecting structures, which is used in infrastructure engineering, building components, building structures, etc., can solve problems such as not being well solved, reducing the effect of waterproofing, and reducing sealing performance, and achieves effective sealing. Connect, ensure the sealing performance, the effect of strong bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

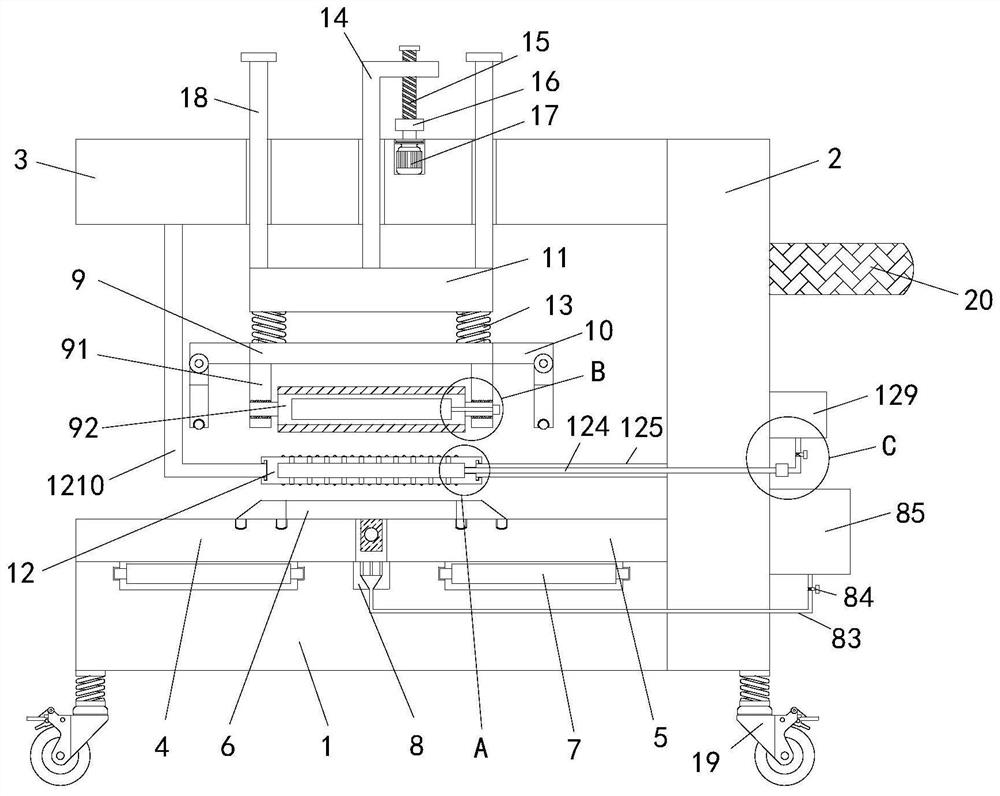

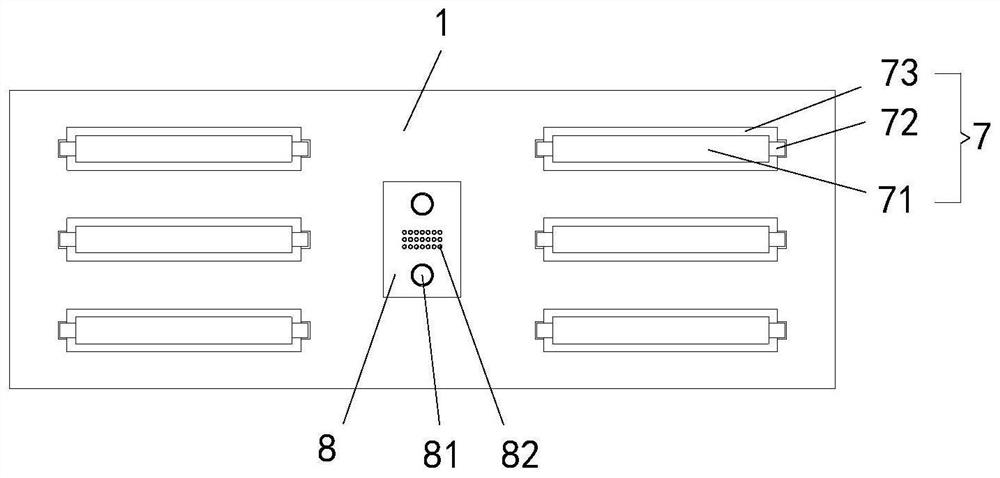

[0044] refer to Figure 1-9 , a waterproof membrane overlapping structure, including a base 1, a support column 2, a horizontal plate 3, a first waterproof membrane 4 and a second waterproof membrane 5, and the base 1 and the horizontal plate 3 are fixedly connected by a support column 2 , the first waterproof roll material 4 and the second waterproof roll material 5 are flatly laid on the upper end of the base 1, and the upper end surfaces of the first waterproof roll material 4 and the second waterproof roll material 5 are fitted with splices 6;

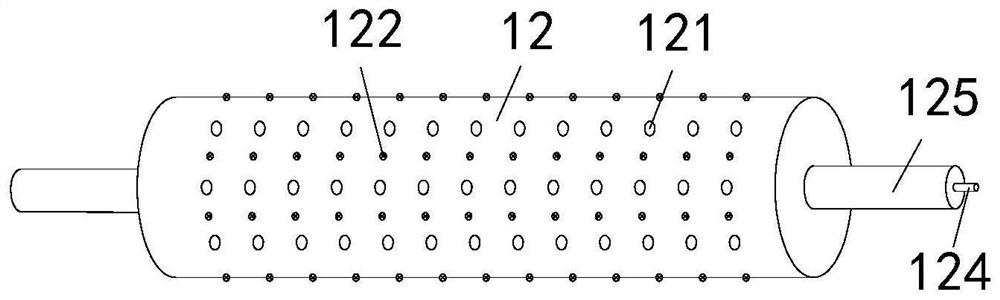

[0045] The lower end of the horizontal plate 3 is fixedly provided with an L-shaped support rod 1210, and the side wall of the support column 2 is horizontally provided with a fixed shaft 125, and the L-shaped support rod 1210 and the fixed shaft 125 are rotatably connected with a glue spray tube 12;

[0046] The inner wall of the horizontal plate 3 is vertically plugged with an L-shaped reciprocating strut 14, the bottom of the L-...

Embodiment 2

[0057] refer to Figure 1-9 , The difference between this embodiment and Embodiment 1 is that the two ends of the installation frame 9 are respectively provided with a limit clamping part 10, and the limit clamping part 10 includes a fixed block 101;

[0058] Both sides of the bottom of the fixed block 101 are respectively rotatably connected with a clamping block 102, and an elastic member 104 is connected between the two clamping blocks 102. The elastic member 104 is a spring, and the bottom of the clamping block 102 is provided with a second rigid ball 103. By setting the second rigid ball 103, the clamping block 102 rolls on the upper end surfaces of the first waterproof coiled material 4 and the second waterproof coiled material 5. When in use, the clamping block 102 is clamped on the first waterproof coiled material 4, the second waterproof coiled material The upper end surface of the second waterproof roll material 5, and under the elasticity of the elastic member 104, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap