A curved variable cross-section flow channel type axial flow gas wave ejector

A technology of variable cross-section and ejector, which is applied in the direction of machines/engines, etc., can solve the problems that the gap between the nozzle and the drum cannot be monitored in real time, the flow loss of large gas injection and discharge, and the difficulty of adjusting the deflection angle between nozzles, etc., to achieve reduction The effect of equipment power consumption, reduction of gas incident and exhaust loss, and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A typical implementation method of a curved variable cross-section flow channel type axial flow gas wave ejector of the present invention is described as follows, but is not limited to this implementation method.

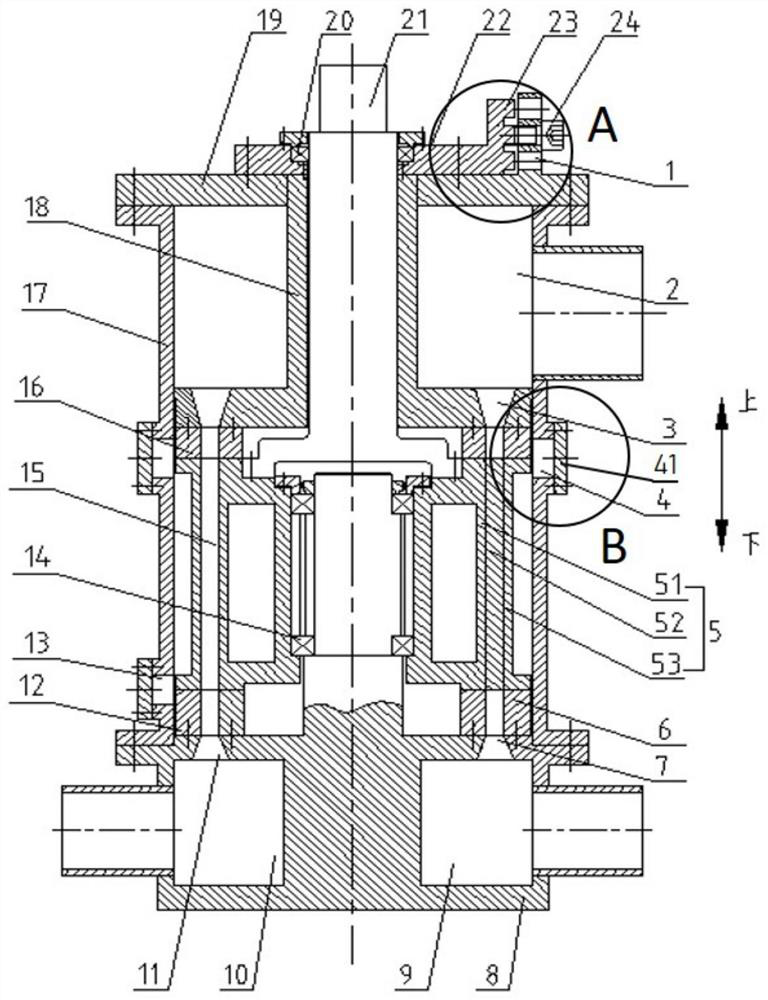

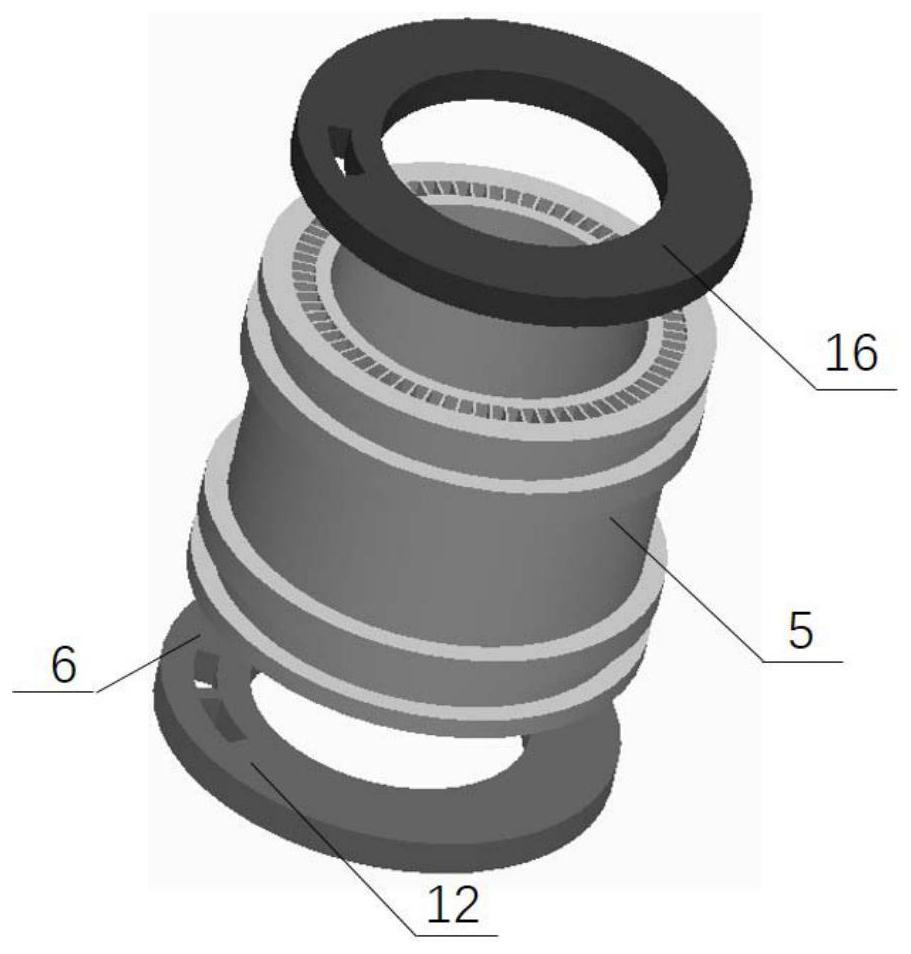

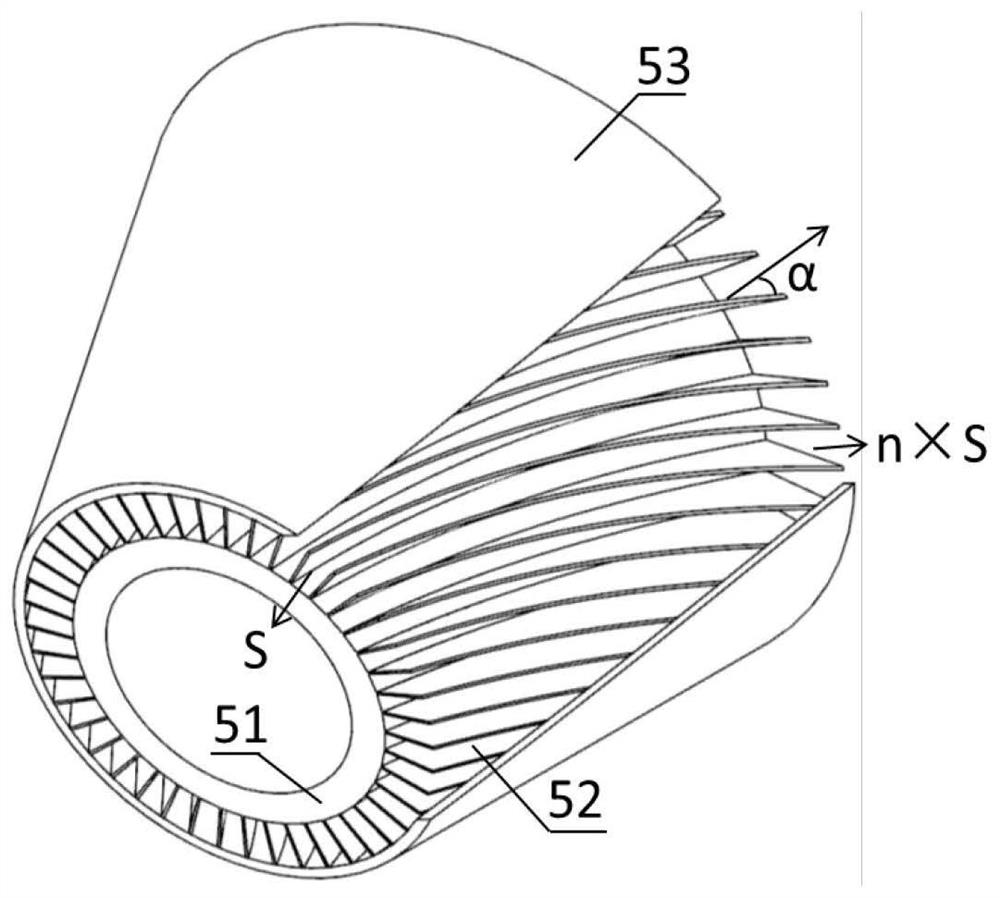

[0026] like figure 1 As shown in the figure, a curved variable-section flow channel type axial flow gas wave ejector of the present invention is mainly composed of a head 19, a transmission shaft 21, a declination adjustment plate 22, a drum 5, a low pressure nozzle 6, a base 8, a high pressure The nozzle 12 , the medium pressure nozzle 16 , the casing 17 and the support plate 18 are composed.

[0027] The casing 17 is a cylindrical structure, and the head 19 and the base 8 are respectively installed on both ends of the casing 17, so that a sealing structure is formed inside the casing 17; And the support plate 18 is located in the casing 17; the angle adjustment plate 22 is located outside the casing 17, and is fixed on the head (19);

[0028] The drum 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com