Floating type thread gauge and automatic thread detection device using same

A detection device and thread thread technology, applied in the field of automatic thread detection devices, can solve the problems of non-replacement, low efficiency, and reduced detection efficiency, etc., and achieve the effects of rapid switching, improved efficiency, and rapid regulation or stoppage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

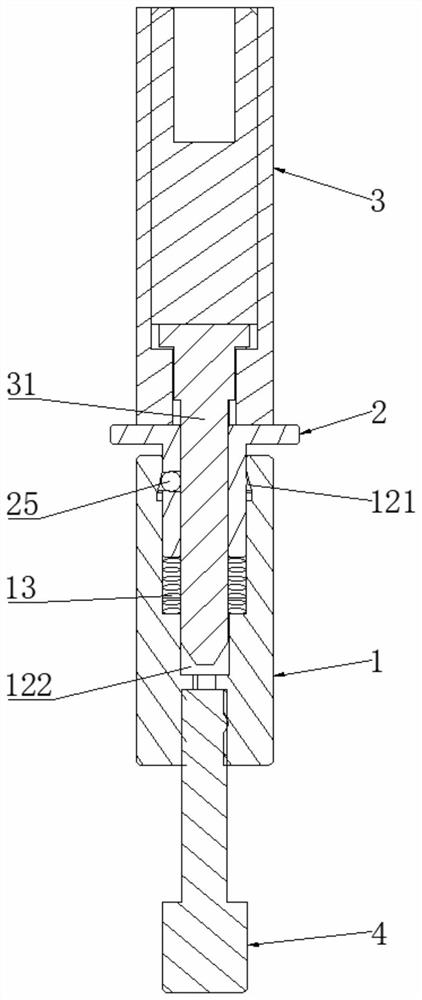

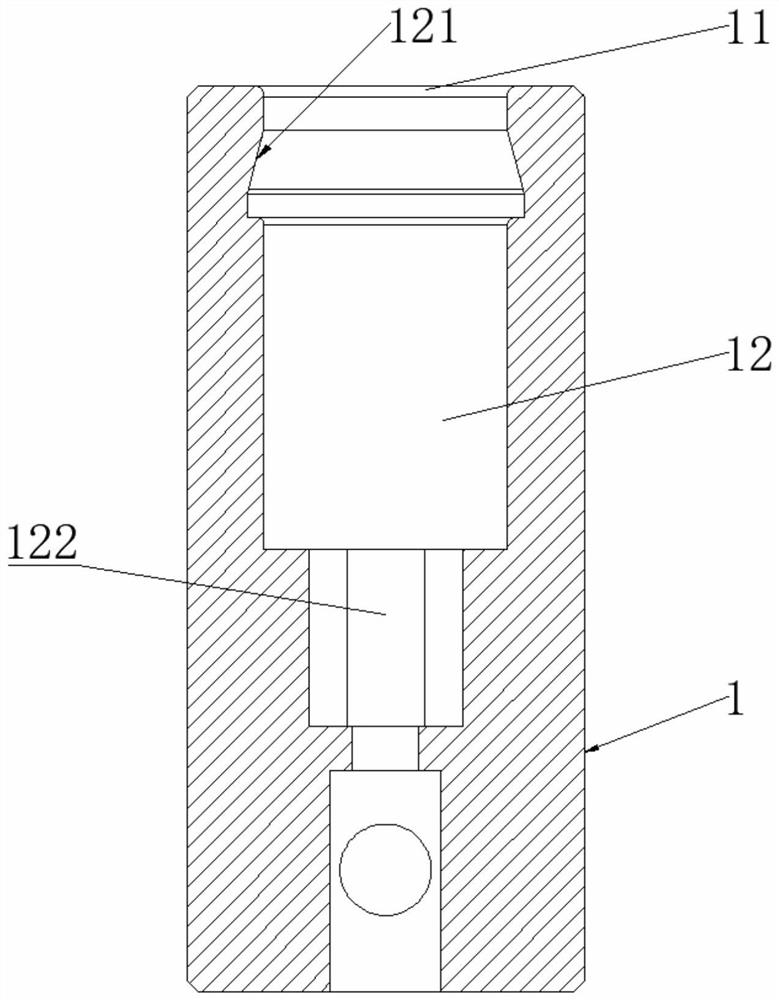

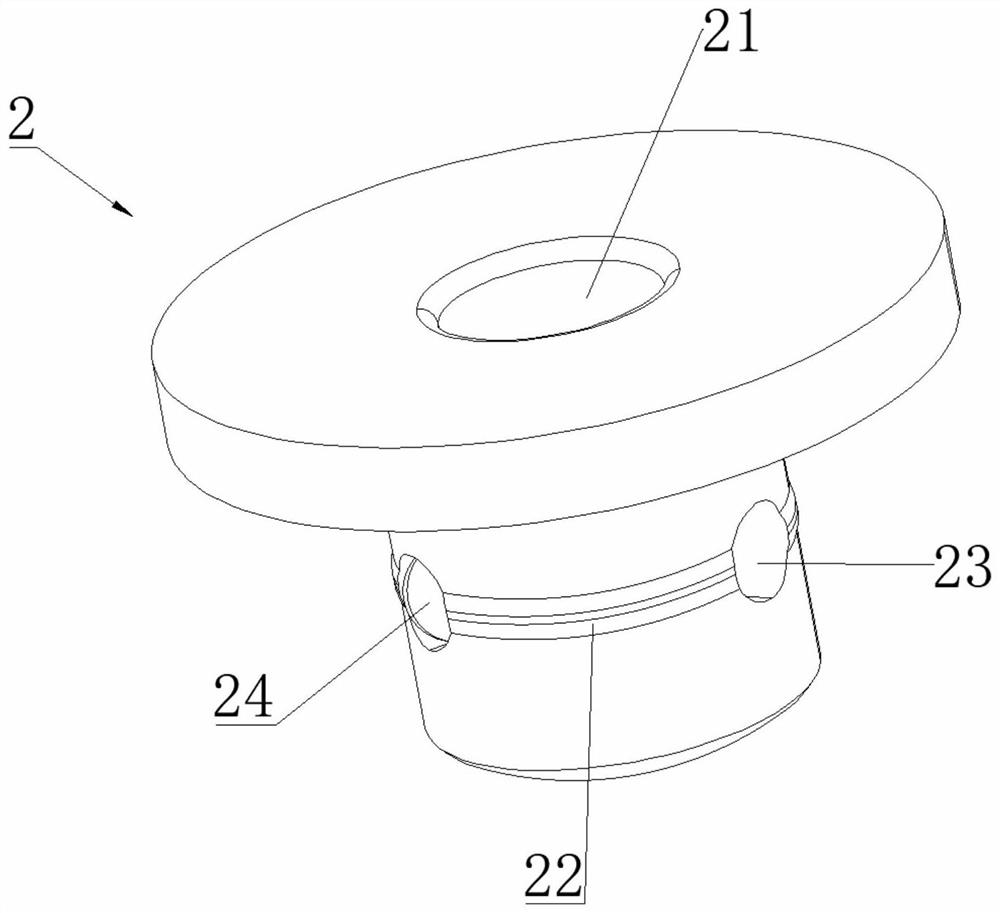

[0034] Such as figure 1 As shown, a floating thread gauge includes: a receiving part 1, a through gauge or a stop gauge 4 is installed at its lower end, the receiving part 1 has an inlet 11 arranged at the upper end and extends downward from the inlet 11 inside the receiving part 1 The channel 12 of the floating part 2, the middle position of which is configured as a through cavity 21 from top to bottom, the lower part of the floating part 2 is hidden in the receiving part 1 and limited in the channel 12, and the side wall of the lower part of the floating part 2 is provided with a movable Locking bead 24, a spring member 13 is set between the bottom end of floating part 2 and receiving part 1, so that floating part 2 can float up and down in a small range along the direction of channel 12; transfer part 3, an insertion part is installed at its lower end 31 , the insertion part 31 is inserted into the through cavity 21 from top to bottom, and is clamped in the through cavity 2...

specific Embodiment 2

[0044]Apply the above-mentioned floating thread gauge to an automatic thread detection device to realize automatic detection of threads, specifically, as Figure 4 with Figure 5 As shown, the automatic thread detection device includes:

[0045] A six-axis robot 5, the six-axis robot 5 has a reversible working head 51, and an adapter 3 is connected to the working head 51; the six-axis robot is a kind of humanoid operation, automatic control, reprogrammable, capable The mechatronics automatic production equipment that completes various operations in three-dimensional space can be used to control the movement of the adapter part, and can perform inspection work with high strength, high precision and high efficiency.

[0046] A base 6, arrange a plurality of receiving parts 1 in rows on the base 6, and each receiving part 1 has a corresponding floating part 2; They are all different, satisfying the thread test of different caliber threads on the product to be tested.

[0047] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com