Method for calculating octane number loss in gasoline catalytic cracking process

A technology of catalytic cracking gasoline and calculation method, which is applied in the field of calculation of octane number loss, can solve the problems of gasoline octane number loss, difficulty, and inability to meet the needs of practical applications, and achieve efficient calculation methods and accurate calculation results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

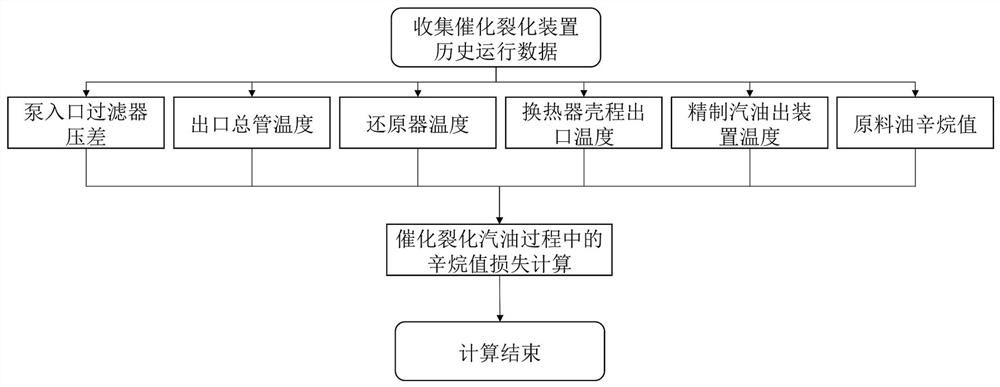

[0015] The present invention provides a kind of calculation method of the octane number loss in catalytic cracking gasoline process, and this method comprises the following steps:

[0016] Step 1, according to the historical operation data of the catalytic cracking gasoline unit, collect the pump inlet filter differential pressure, outlet main pipe temperature, reducer temperature, heat exchanger shell side outlet pipe temperature, refined gasoline output Calculation parameters such as device temperature and octane number data of raw oil;

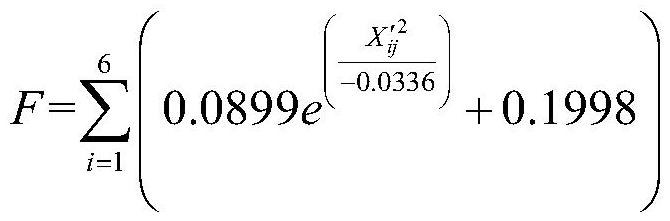

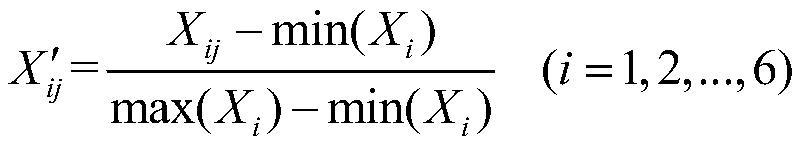

[0017] Step 2: Substituting the processed data into the formula to calculate the octane number loss in the process of catalytic cracking gasoline, the specific calculation formula is:

[0018]

[0019]

[0020] In the formula: F is the octane number loss in the process of catalytic cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com