Grasshopper-based complex variable-density porous structure modeling method

A technology of porous structure and modeling method, applied in 3D modeling, image data processing, special data processing applications, etc., can solve problems such as poor controllability, difficult construction, and singleness of variable-density porous structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

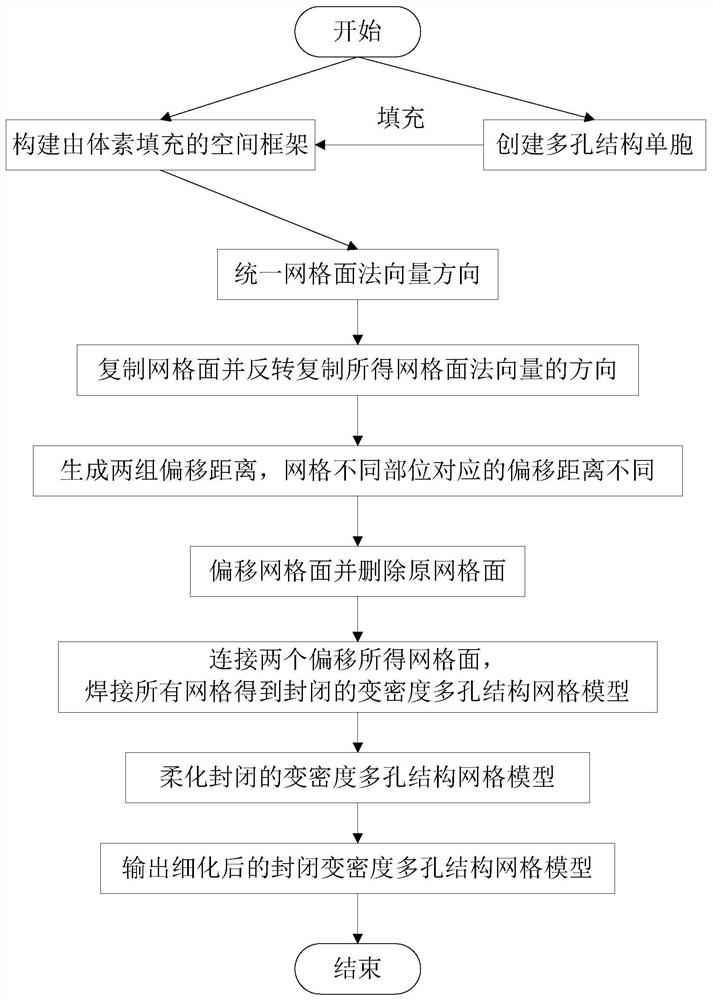

[0060] Such as figure 1 As shown, the present embodiment provides a Grasshopper-based complex variable density porous structure modeling method, including the following steps:

[0061] S1: Use Grasshopper to establish a space frame for filling porous structures, and fill in voxels in the space frame;

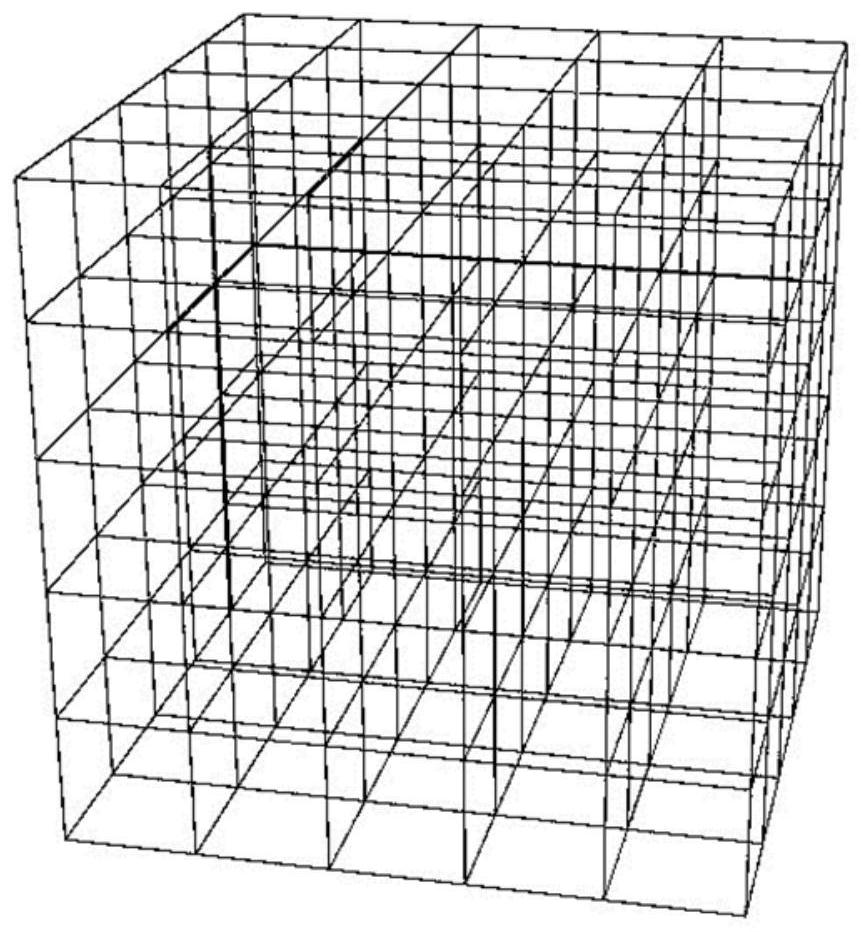

[0062] Such as figure 2 As shown, in order to make the unit cells filled into voxels and scaled in equal proportions along the x, y, and z directions, the voxels in step S1 are all cubes with the same size; the size of the voxels may be different from the size of the outer contour of the unit cells , when filling, the unit cell will be scaled to fit the size of the voxel, and the voxel is a cube to ensure that the unit cell structure does not deform.

[0063] S2: Use Grasshopper to construct a porous structure unit cell;

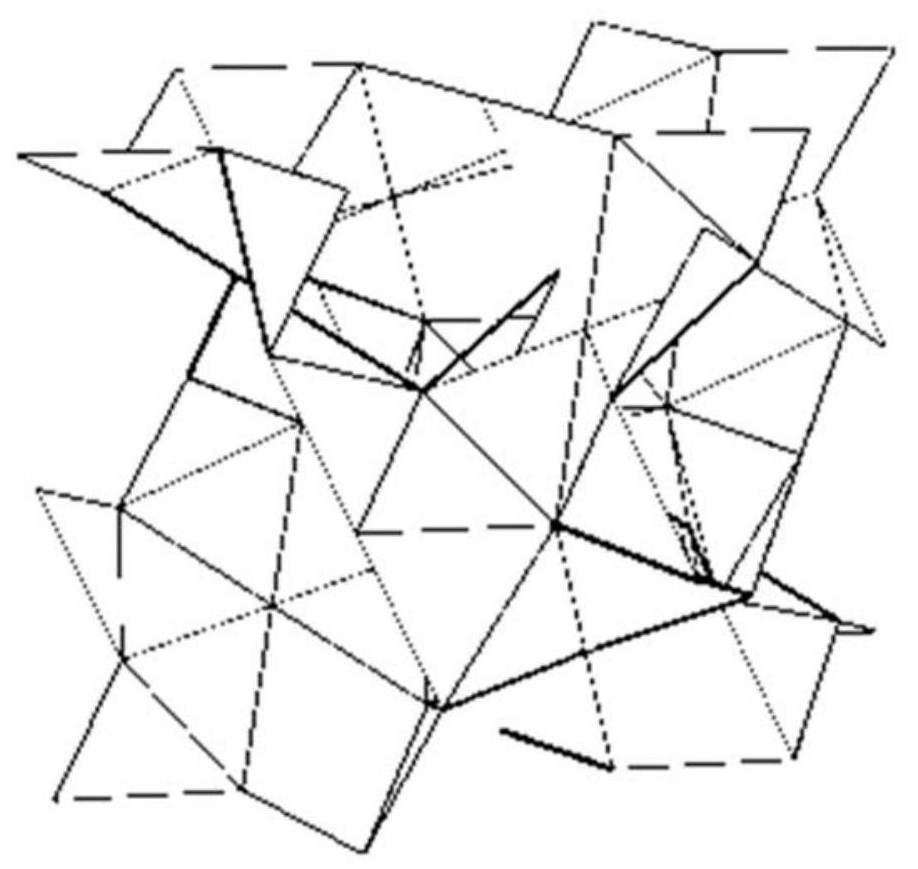

[0064] Such as image 3 As shown, in order to make the subsequent offset grid surface and generate variable density porous structure normally, the unit c...

Embodiment 2

[0087] A complex variable density porous structure modeling system based on Grasshopper, including: space frame building block, voxel filling block, porous structure unit cell building block, porous structure unit cell filling block, normal vector direction unification block, grid surface replication And the normal vector direction reversal module of the mesh surface, the offset distance generation module, the mesh offset module, the mesh surface edge connection mesh generation module, the welding module and the softening module;

[0088] In this embodiment, the space frame building block is used to construct a space frame for filling porous structures using Grasshopper;

[0089] In this embodiment, the voxel filling module is used to fill in voxels in the space frame;

[0090] In this embodiment, the porous structure unit cell building block is used to construct the porous structure unit cell using Grasshopper;

[0091] In this embodiment, the porous structure unit cell fill...

Embodiment 3

[0100] This embodiment provides a storage medium, the storage medium can be a storage medium such as ROM, RAM, magnetic disk, optical disk, etc., and the storage medium stores one or more programs. Grasshopper's method for modeling complex variable density porous structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com