Production method of edible seasoning

A production method and seasoning technology, applied in chemical instruments and methods, food science, feeding devices, etc., can solve problems such as difficult water contact and rapid response, low utilization rate of raw materials, and easy to form lumps immediately, etc. To achieve the effect of improving utilization rate, increasing degree of hydrolysis and increasing reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

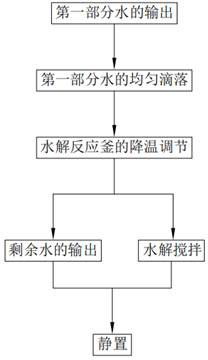

[0076] like figure 1 Shown, a kind of food seasoning production method comprises:

[0077] Step 1, the first part of water output, the water in the water container a21 is sent into the hydrolysis reactor 1, and the water reacts with the processing raw materials in the hydrolysis reactor 1. As the water in the water container a21 gradually decreases, the expansion unit a242 The telescopic unit a242 moves up and drives the first transmission gear 234 to rotate through the first transmission rack 235, and the rotating first transmission gear 234 drives the swing plate 232 to swing, and then gradually opens the water outlet of the first transmission water pipe 22, and the water is slowly Sustained incremental delivery into the storage bag 32;

[0078] Step 2, the first part of the water drips evenly. When the water flow in the storage bag 32 increases, the bearing ring 331 stretches the unit g332 downward, and the fourth transmission rack 333 drives the fourth transmission gear 3...

Embodiment 2

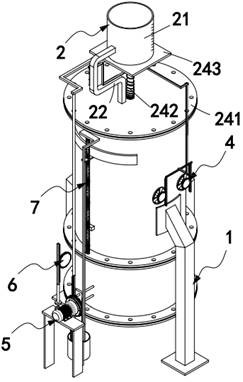

[0093] like figure 2 As shown, a temperature-controlled and adjustable hydrolysis reactor includes a hydrolysis reactor 1, and also includes a primary transmission mechanism 2 arranged above the hydrolysis reactor 1, arranged at the lower end of the primary transmission mechanism 2 and located at the The uniform blanking mechanism 3 in the hydrolysis reactor 1, the cooling mechanism 4 installed in the hydrolysis reactor 1, and the secondary transmission mechanism 5 arranged at the bottom of the hydrolysis reactor 1, the secondary transmission mechanism 5 passes through The first transmission mechanism 6 drives the water in the cooling mechanism 4 to enter the uniform blanking mechanism 3, and the primary transmission mechanism 2 drives the cooling mechanism 4 through the second transmission mechanism 7 to control the temperature in the hydrolysis reactor 1;

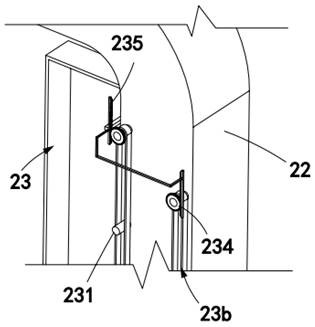

[0094] The primary transmission mechanism 2 includes a water container a21, a first water transfer pipe 22 that is arr...

Embodiment 3

[0146] like Figure 8 to Figure 10 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below. The difference between this embodiment three and embodiment two is:

[0147] further, such as Figure 8 to Figure 10 As shown, the storage bag 32 is hollow and has several groups of air bag holes 34 protruding downward from its bottom;

[0148] The third transmission mechanism 33 includes a bearing ring 331 arranged below the storage bag 32, a telescopic unit g332 fixedly connected below the bearing ring 331 and installed on the inner wall of the hydrolysis reactor 1 through a base, and The fourth transmission rack 333 fixedly connected to the telescopic unit g332, the fourth transmission gear 334 meshed with the fourth transmission rack 333, the fourth transmission gear 33...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com