Adjusting type guide rail for electrical installation and bending device thereof

A technology for electrical installation and bending devices, applied in cleaning methods and tools, cleaning methods using tools, chemical instruments and methods, etc., can solve the problem of inability to conveniently observe the values of electrical components, affect the normal production of guide rails, and the positioning of sheets Inaccurate and other problems, to achieve the effect of improving the appearance, safe and convenient use, and preventing scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

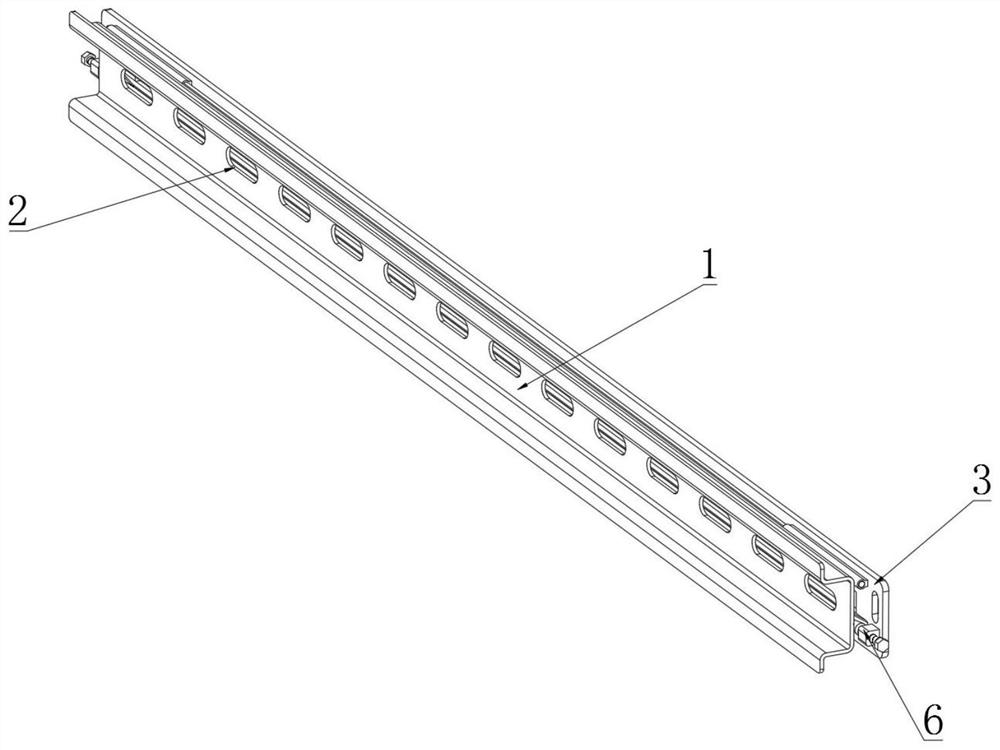

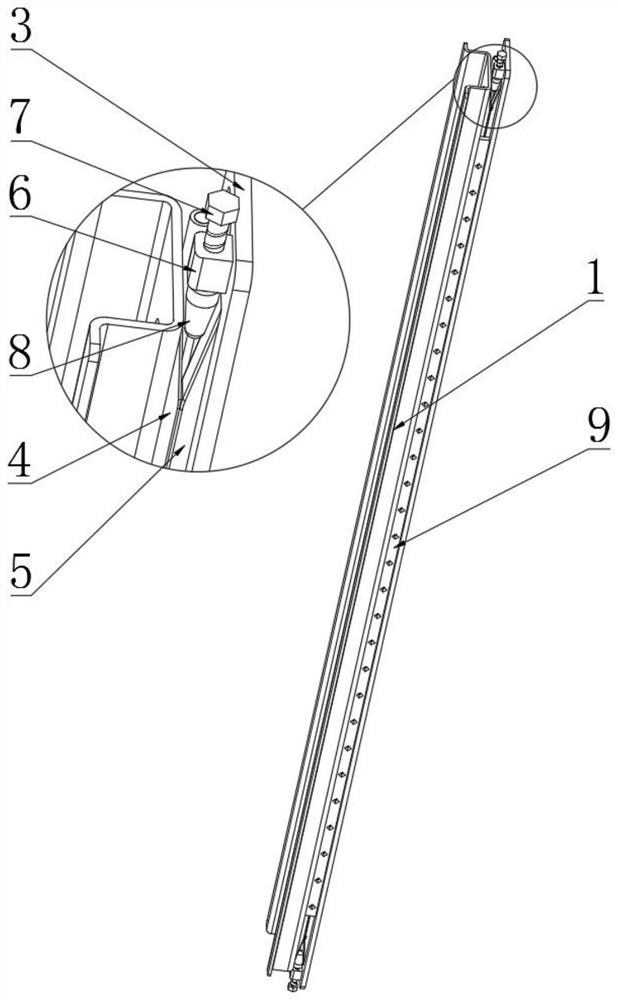

[0048] Example: such as Figure 1-2 As shown, the present invention provides a technical solution, an adjustable guide rail for electrical installation, including a guide rail main body 1, the middle part of the inside of the guide rail main body 1 is uniformly opened with a long installation hole 2, and the top of the back of the guide rail main body 1 is rotated through a shaft. The base plate 3, the driving inclined block 4 is bonded to the bottom of the back of the guide rail main body 1, the limit inclined block 5 is bonded to the bottom of the front of the mounting base plate 3, and the bottom of both ends of the front of the mounting base plate 3 is fixedly connected to the mounting small block 6, and the inner middle of the mounting small block 6 The driving bolt 7 is connected by thread, and the end of the driving bolt 7 is fixedly connected with the driving cone block 8 at the position between the driving slant block 4 and the limit slanting block 5. Limiting rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com