Inclined tape film conveying device

A kind of conveying device, inclined technology, applied in the field of inclined film conveying device, can solve the problems such as loose film and affect the use effect of braiding machine, and achieve the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

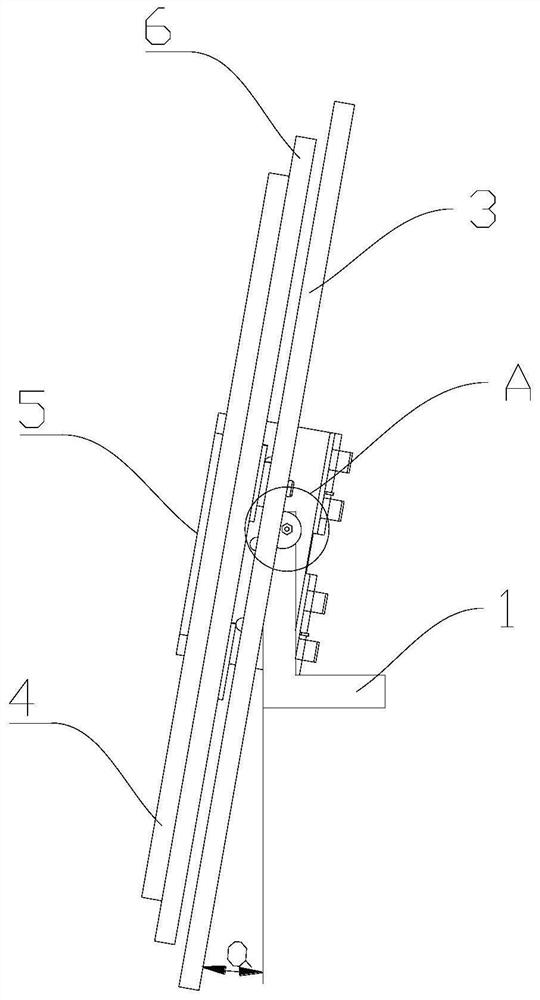

[0034] Please refer to Figure 1 - Figure 7 In this embodiment, the present embodiment provides an inclined membrane conveying device including a transport device and a bracket assembly, and the transport device is inclined to the bracket assembly, and the inclination angle between the transporting device and the bracket assembly is an acute angle.

[0035] In the present embodiment: When the present incline-by-film conveying device is required to convey the belt film, the staff can detach the membrane transport device on the commercially available automatic tape, and then transport the inclined belt film through the bracket assembly. The device is mounted to the commercially available automatic brace machine, and thereby replacing the original belt film transport device using the present inclined membrane conveying device, and then winding the belt film to the transport device of the inclined belt film delivery device, performing a belt transportation Since the transport device is...

Embodiment 2

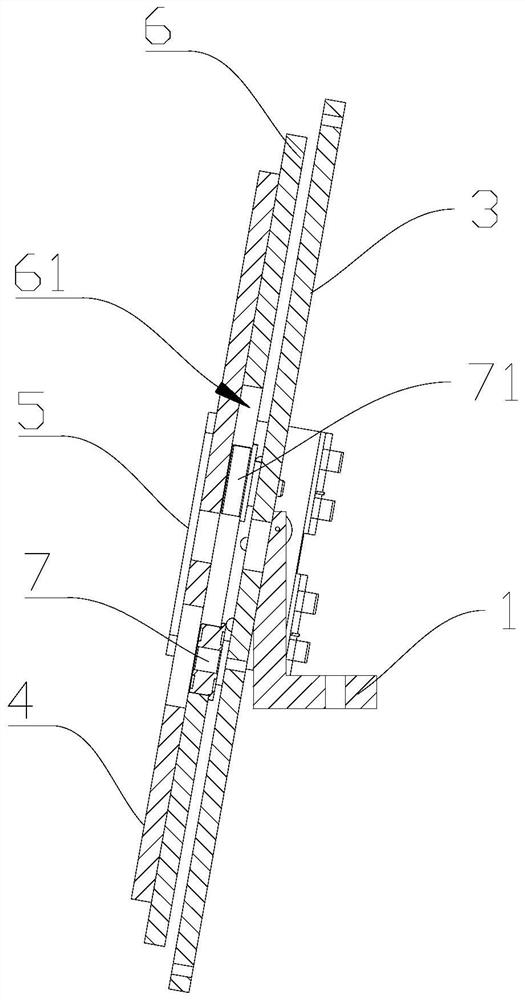

[0041] Please refer to Figure 1 - Figure 7 According to the first embodiment, the present embodiment is provided with an inclined belt film delivery device, and the difference from the first embodiment is that the stent assembly includes mounting bracket 1 and between the transporting device and the mounting bracket 1 described above. The adjustment assembly of the tilt angle, the mounting bracket 1 is rotatably connected to the transport device through the adjustment assembly.

[0042] In the present embodiment: the bracket assembly includes a regulating assembly mounting bracket 1 and an adjustment assembly for adjusting the inclination angle between the transport device and the mounting bracket 1, and the mounting bracket 1 is rotated by the adjustment assembly and the transport device, and the staff can work according to the actual work. The inclination angle between the transport device and the mounting bracket 1 is adjusted by the adjustment assembly, thereby ensuring the tr...

Embodiment 3

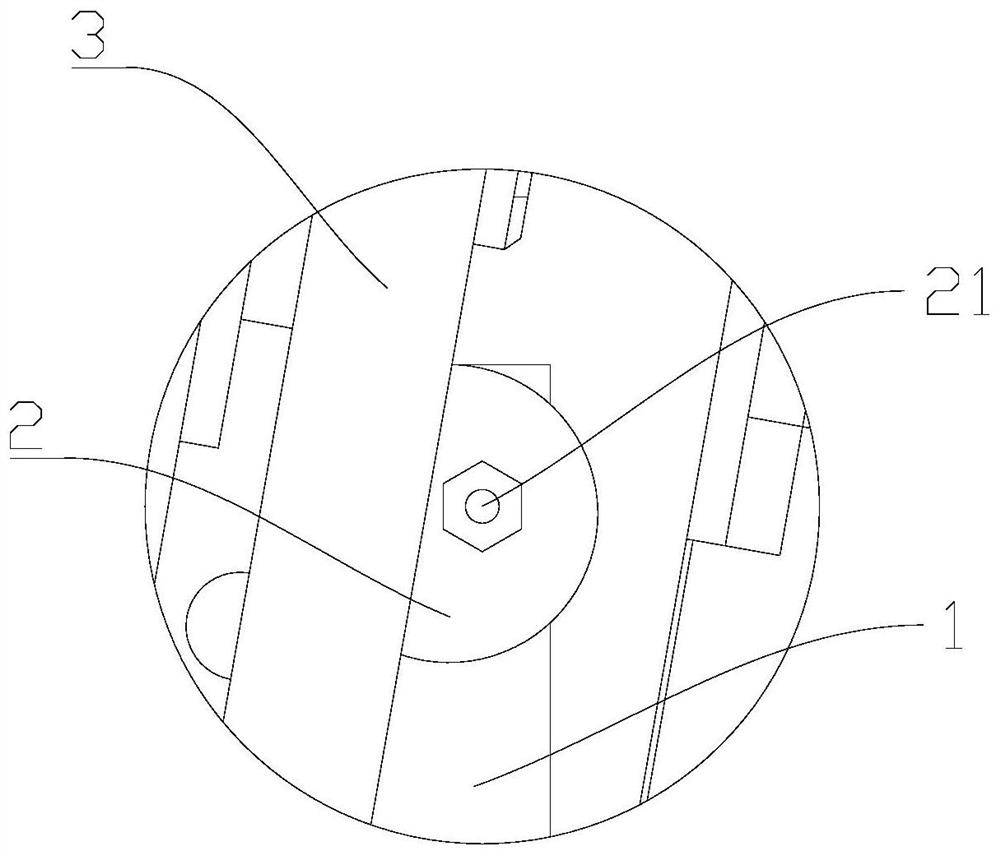

[0046] Please refer to Figure 1 - Figure 7 According to any of the above embodiment, the present embodiment is provided with an inclined belt film delivery device, and the difference from any of the above-described modulating assemblies includes a connecting sleeve 2 and a regulating bolt 21. In the above-described transport device, the mounting bracket 1 is rotatably connected to the transporting sleeve 2, and the adjustment bolt 21 is provided at the connection sleeve 2 and the rotational connection of the mounting bracket 1.

[0047] In the present embodiment: the adjustment assembly includes a connection sleeve 2 and a regulating bolt 21, a connection sleeve 2 is provided in a transport device, and the mounting bracket 1 is rotatably connected by the connection sleeve 2, and the adjustment bolt 21 is provided in the connection sleeve 2 and the mounting bracket 1. When the worker needs to adjust the inclination angle between the transport device and the mounting bracket 1, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com