Thermal expansion casing pipe shackle method and device

An expansion casing and thermal technology, applied in casing, drill pipe, earthwork drilling, etc., can solve the problems of shackle failure, adhesion between the pipe body and the coupling thread connection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present invention provides a method for breaking off a heat expansion casing, wherein the method for breaking off a heat expansion casing includes:

[0037] In the inside of the casing, the part of the casing to be disassembled is continuously heated, so that the ends of the two pipe bodies at the part of the casing to be disassembled and the couplings connecting the two pipe bodies are heated to the same temperature to ensure that the two The expansion state of the pipe body and the coupling is the same;

[0038] Apply breakout torque to the casing at the wellhead so that the casing is always under stress;

[0039] In the inside of the casing, cool the part of the casing to be disassembled, so that the temperature of the two pipe bodies is lower than the temperature of the coupling, so that a gap is formed between the two pipe bodies and the coupling due to thermal expansion and contraction;

[0040] Since the shackle torque is always applied to the casing, at thi...

Embodiment 2

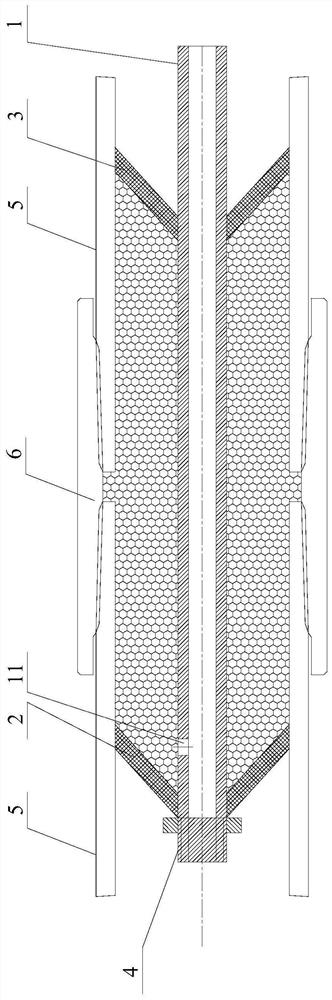

[0053] Such as figure 1 As shown, the present invention also provides a thermal expansion casing breakout device, wherein the thermal expansion casing breakout device includes: a central pipe 1, a first packer 2 and a second packer 3, the first packer Both the packer 2 and the second packer 3 are sealed and positioned and sleeved on the center pipe 1, and the first packer 2 and the second packer 3 can be respectively connected to the two pipe bodies 5 of the casing to be disassembled. The inner surfaces of the pipes are sealed and positioned so that the connection between the two pipe bodies 5 is located between the first packer 2 and the second packer 3, the two pipe bodies 5, the collar 6 connecting the two pipe bodies 5, The first packer 2, the second packer 3 and the central pipe 1 enclose and form a closed annular space. By passing chemicals into the annular space, the ends of the two pipe bodies 5 and the joints connecting the two pipe bodies 5 can be sealed. The coupli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com