Pneumatic engine and control system

A pneumatic engine and engine technology, applied in the field of automobile engines, can solve problems such as unsustainable development and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

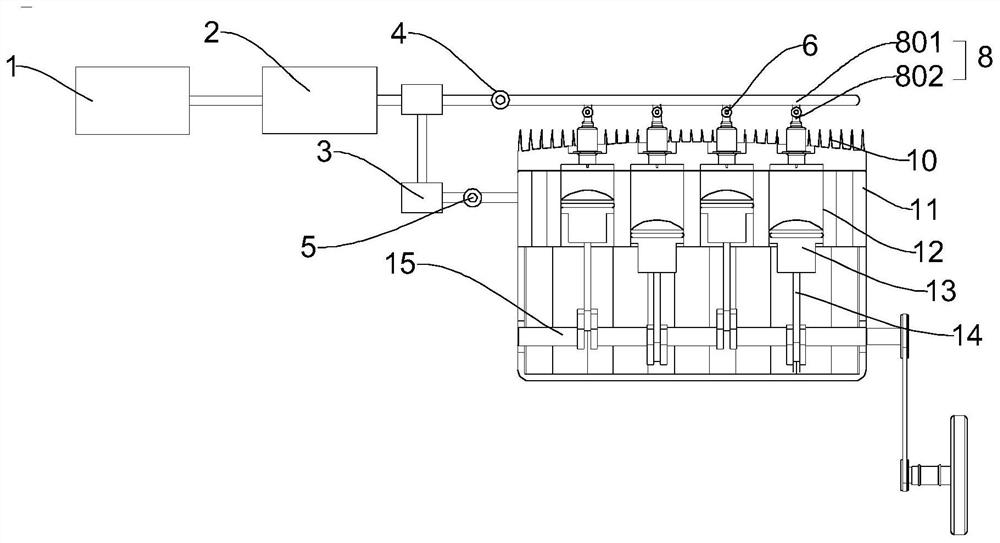

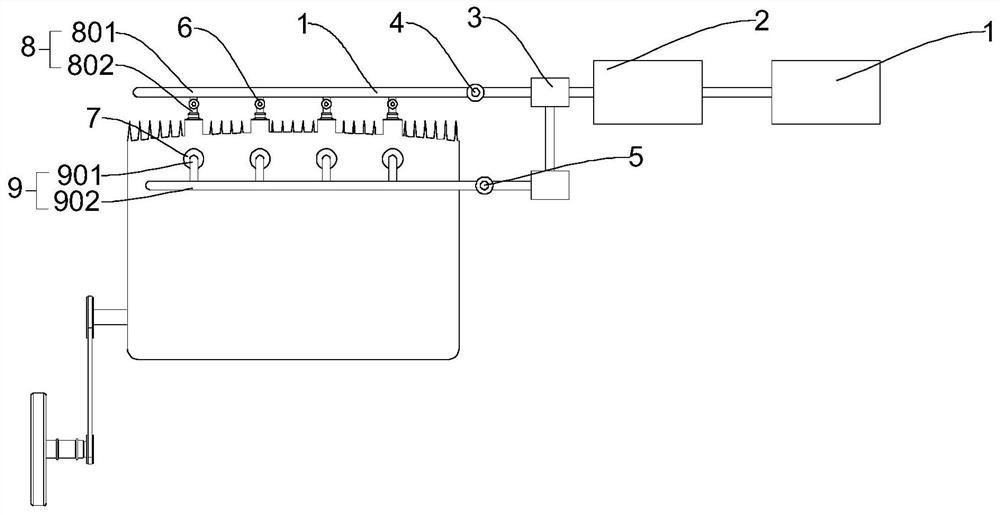

[0045] Please refer to figure 1 , figure 2 , this embodiment provides an embodiment of this application to provide a pneumatic engine, including:

[0046] engine casing 11;

[0047] Cylinder, the above-mentioned cylinder is horizontally arranged in the above-mentioned engine casing 11, and the above-mentioned cylinder forms a horizontal driving system, and the above-mentioned cylinder includes a cylinder block 12, and a piston 13 that is slidably arranged in the above-mentioned cylinder block 12, and the above-mentioned piston 13 is connected with a drive connection Rod 14, the free end of the above-mentioned driving connecting rod 14 is connected with a power output shaft 15, and the above-mentioned cylinder body 12 is also provided with an air inlet and an exhaust port;

[0048] Air intake assembly, the air intake assembly includes an electric air pump 1, the electric air pump 1 is connected with an air intake pipe 8, the free end of the air intake pipe 8 is connected wit...

Embodiment 2

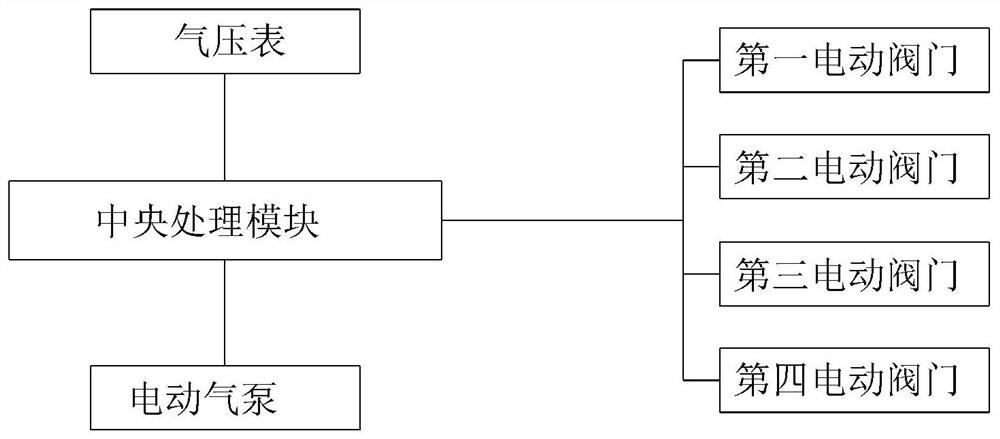

[0068] Please refer to Figure 1-Figure 3 , the present embodiment provides a control system of a pneumatic engine, including the above-mentioned pneumatic engine, and also includes a central processing module, and the central processing module is simultaneously connected with the first electric valve 4, the second electric valve 5, the third electric valve 6, The fourth electric valve 7 is connected with the above-mentioned electric air pump 1 .

[0069] The central processing unit (CPU, English: Central Processing Unit / Processor) is one of the main equipment of the electronic computer and the core accessory in the computer. Its function is mainly to interpret computer instructions and process data in computer software. All operations in the computer are the core components that the CPU is responsible for reading instructions, decoding instructions, and executing instructions. It can control the opening or closing of the first electric valve 4, the second electric valve 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com