Micro-channel flat tube, micro-channel heat exchanger and air conditioner

A technology of micro-channel and micro-porous channel, applied in evaporator/condenser, tubular element, heat exchange equipment, etc., can solve the problems of small number of micro-pores, uneven wall thickness, ineffective heat exchange, etc. The effect of deformation capacity, increasing total cross-sectional area, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

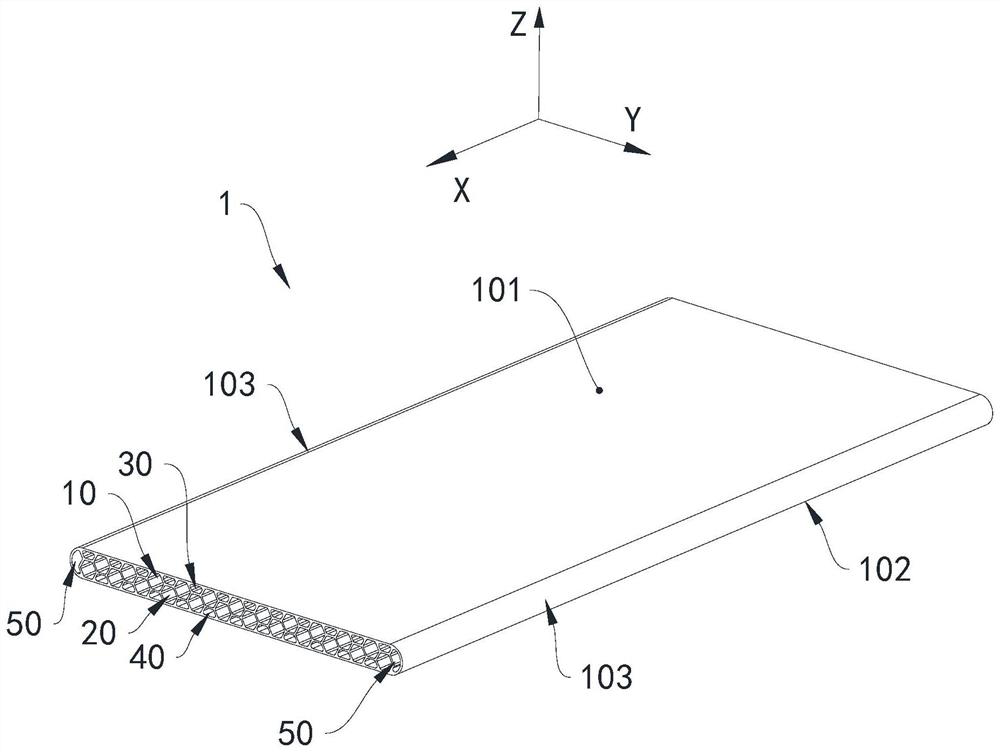

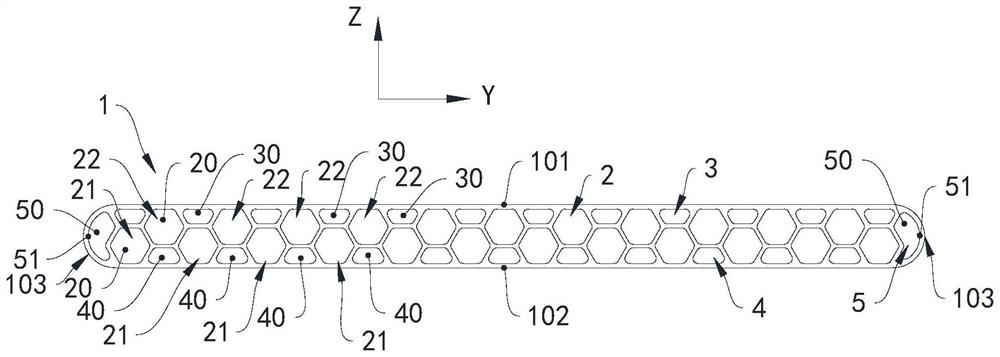

[0054] see Figure 1 to Figure 3 , The air conditioner in this embodiment includes a microchannel heat exchanger, and the microchannel heat exchanger includes a plurality of microchannel flat tubes 1 arranged in parallel.

[0055] The microchannel flat tube 1 includes a honeycomb micropore channel 10 , and the micropore channel 10 includes a first micropore unit 2 , a second micropore unit 3 , a third micropore unit 4 and a fourth micropore unit 5 .

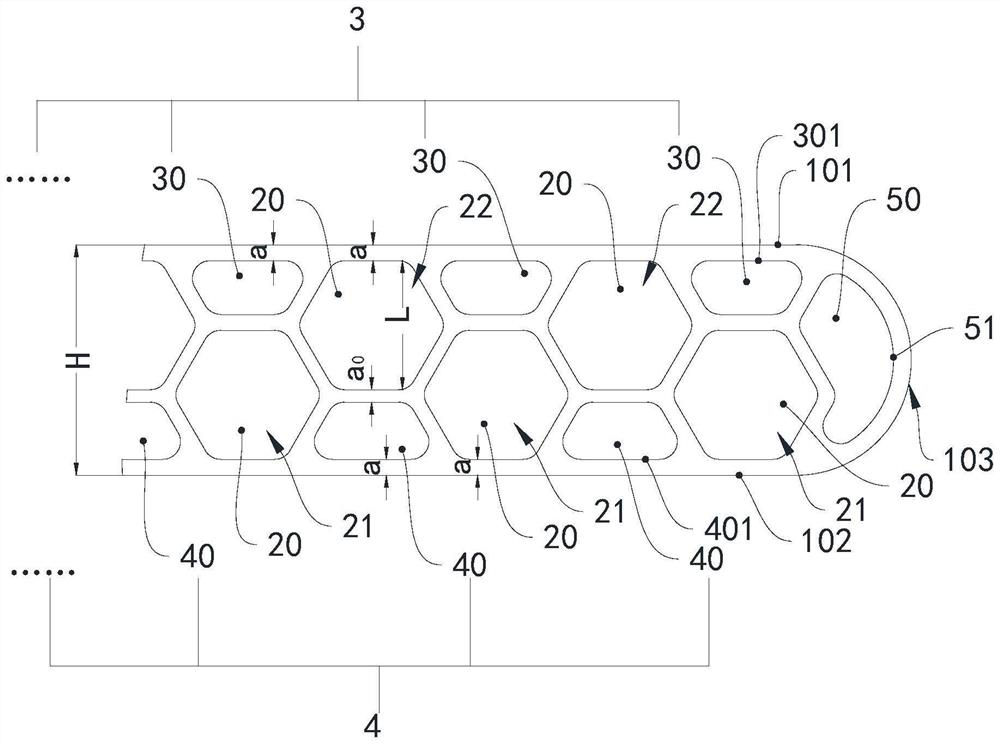

[0056] The first microhole unit 2 includes a plurality of first microhole groups 21 and a plurality of second microhole groups 22, along the width direction Y (ie the second direction) of the microchannel flat tube 1, the first microhole groups 21 and The second microhole groups 22 are arranged alternately in sequence.

[0057] Each first microhole group 21 includes a first microhole 20 , and each second microhole group 22 includes a first microhole 20 . The first microholes 20 all extend along the length direction X (i.e. the ...

no. 2 example

[0078] As the description of the second embodiment of the microchannel flat tube, microchannel heat exchanger and air conditioner of the present invention, only the difference from the first embodiment of the above microchannel flat tube, microchannel heat exchanger and air conditioner will be given below illustrate.

[0079] see Figure 9 , in this embodiment, the first micropore unit 200 includes a plurality of first microhole groups 221 and a plurality of second microhole groups 222, and each first microhole group 221 includes a plurality of first microhole groups arranged along the thickness direction Z. Microholes 220 , each second microhole group 222 includes a plurality of first microholes 220 arranged along the thickness direction Z. The number of first microholes 220 in each first microhole group 221 is one more than the number of first microholes 220 in each second microhole group 222. In this embodiment, the number of first microholes 220 in each first microhole gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com