Lead-acid battery grid with half-ribsarranged inpositive and reverse staggered mode

A lead-acid battery, dislocation arrangement technology, applied in the direction of battery pack parts, circuits, electrical components, etc., can solve the problem of not achieving the expected effect of the electrochemical reaction, increasing the number of transverse ribs, and not reaching the cycle life of the lead-acid battery, etc. problem, to achieve the effect of reasonable structure, reducing current density and improving cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

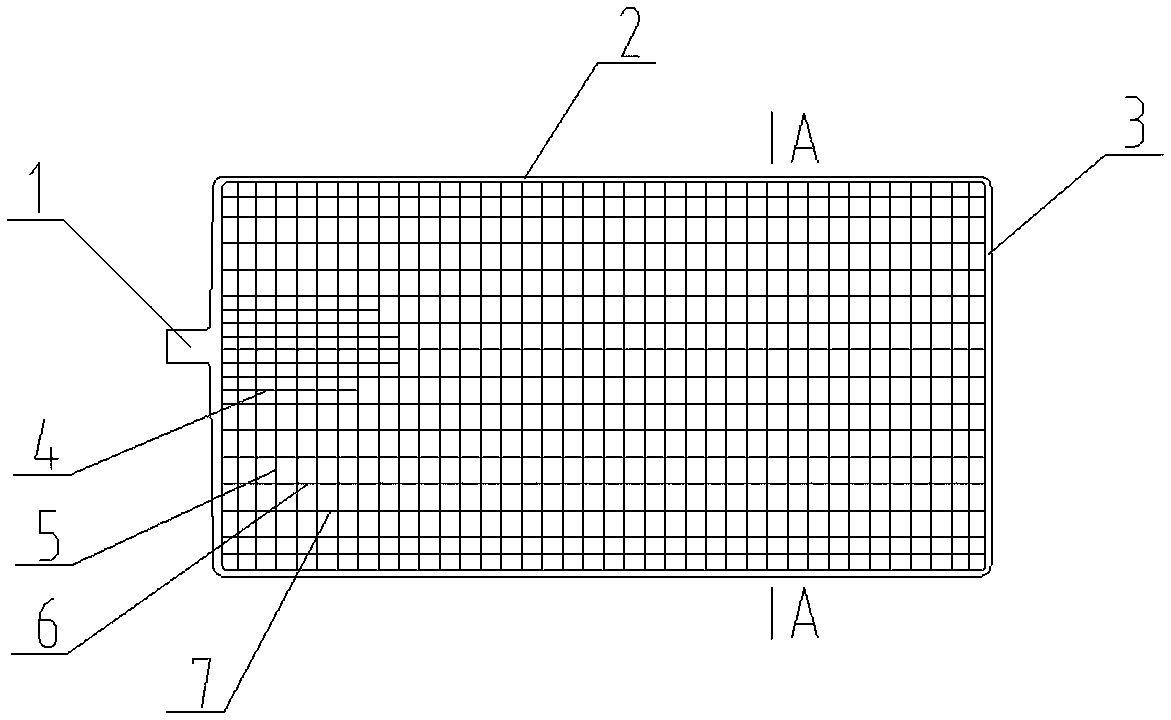

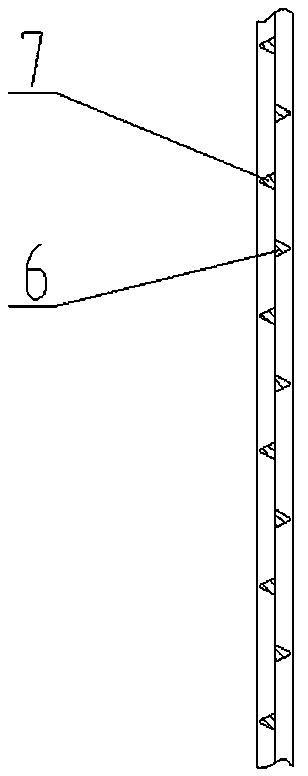

[0016] figure 1 The lead-acid battery grid with half-ribs arranged in dislocation in front and back is shown as a rectangular sheet-shaped member with dense grids. It consists of tab 1, horizontal frame 2, vertical frame 3, short horizontal rib 4, vertical rib 5, front horizontal rib 6 and reverse horizontal rib 7. In the figure, the outer edge of the vertical frame 3 on the left is provided with tabs 1 . The short transverse rib 4 is a new component whose length is shorter than that of the front transverse rib 6 or the reverse transverse rib 7 . In this embodiment, the short transverse rib 4 is only 1 / 4 of the length of the front transverse rib 6 . The cross section of the short transverse rib 4 is the same as the vertical frame 3 connected with each other, which is short and has equal width on four sides. In the structure, the shor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com